A smart mirror laser engraving machine is a kind of equipment specially designed and developed for the mirror manufacturing industry. With the development of technology, consumers are more and more interested in smart home products. Smart mirrors have begun to be recognized by the market and become part of high-end home decoration.

The production of smart mirrors is inseparable from the processes of paint removal and sandblasting. In contrast, the traditional mirror paint removal and sandblasting process is complicated and requires many consumables. Laser equipment does not require any consumables, only computer typesetting and one-time molding, which is much faster than traditional methods.

Therefore, the demand for smart mirror laser engraving machines is increasing daily.

What is smart mirror laser engraving machine?

The introduction of smart mirror laser engraving machine

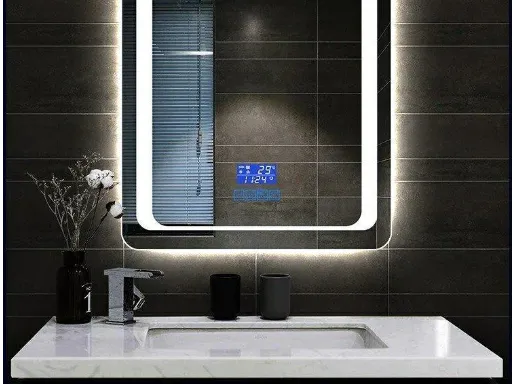

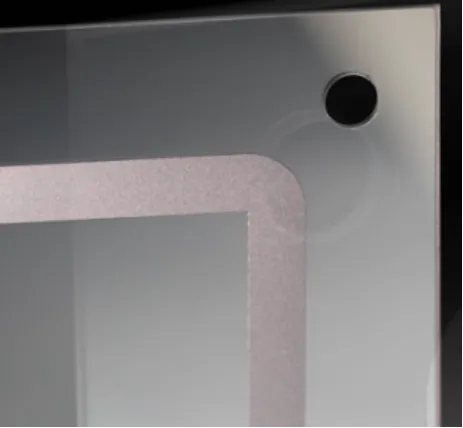

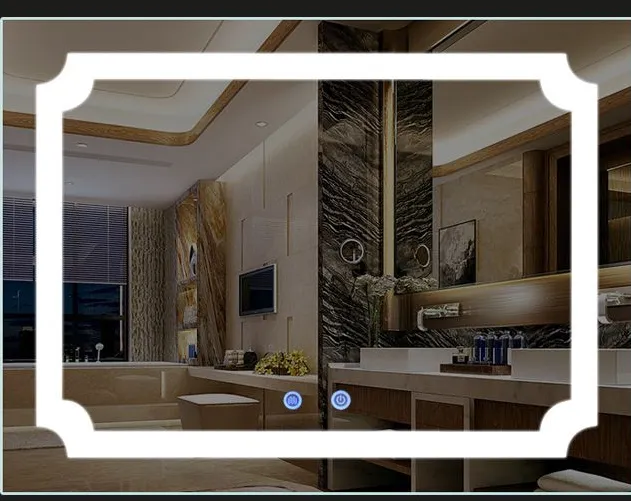

A smart mirror is a device that integrates mirror and smart display technology. It not only provides the function of a regular mirror, but also provides the ability to interact with people and display information, which can be combined with cloud services and has broad application prospects. The texture patterns on smart mirrors can be designed according to your preferences, including transparent areas, mirror buttons, and texture patterns. Simple mirrors can be transformed into eye-catching works through laser engraving, providing personalized customization services.

The smart mirror laser engraving machine is an essential tool for the personalized development of smart mirrors. By adopting high-precision and non-contact processing technology, traditional processes such as coating, marking, paint removal, and sandblasting have been simplified, and processing requirements can be completed in one process, significantly improving production efficiency.

How does it work?

The core component of the smart mirror laser sandblasting machine is the laser, which can generate a high-energy laser beam. By controlling the energy and focal position of the laser beam on the glass surface, the focused laser beam irradiates the glass surface with extremely high power density, rapidly heating, evaporating, or melting the material on the glass surface, forming small pits to achieve matte or textured effects.

Alternatively, the glass can be instantly heated and melted or vaporized to create cutting lines or high-precision markings. Laser removal of reflective material on the back of the smart mirror will produce a transparent effect for lighting design using light strips.

Types of smart mirror laser engraving machines

Smart mirror laser engraving machines can be divided into two types according to their functions: single function and multi-function. Single function only has one function, such as drilling, surface marking, sandblasting, or back paint removal, which is suitable for specific processing needs. Multi-function is to integrate the above single functions, which are divided into 3-in-1 and 4-in-1. The following is a detailed introduction to them:

1. Laser markingmachine for smart mirror

Smart mirror laser marking machine is a device specially used to mark the surface of smart mirrors and engrave brand logos and decorative patterns. The marking content can include text, patterns, barcodes, QR codes, etc.

2. Laser sandblasting machine for smart mirror

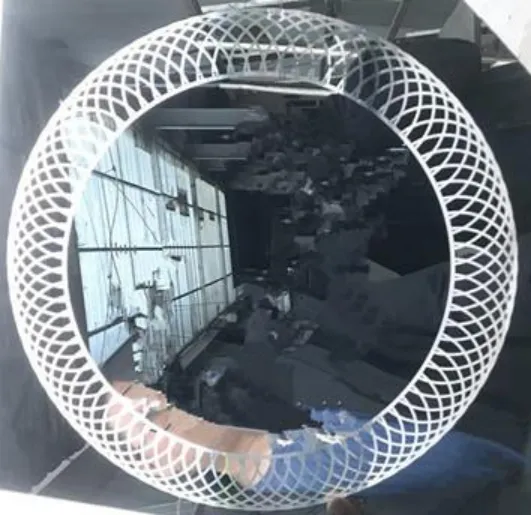

Smart mirror laser sandblasting machine is a device specially used for artistic sandblasting on mirror surfaces to form unique decorative patterns. It can achieve a uniform and consistent sandblasting effect on the mirror surface.

3. Laser paint removal machine for smart mirror

Smart mirrors laser paint remover is a device specially used to remove the coating on the back of smart mirrors. It can form a light-transmitting area and achieve a backlight decorative effect. Laser paint removal does not require chemicals, is environmentally friendly and safe.

4. Laser drilling machine for smart mirror

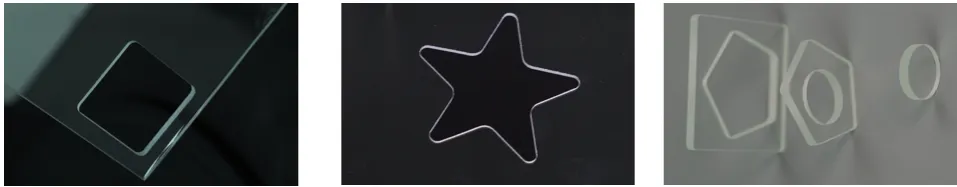

Smart mirror laser drilling machine is a device specially used for drilling holes on smart mirrors. Laser drilling is not limited to circular holes, but can realize holes of various shapes to meet different design requirements.

5. 3-in-1 laser engraving machine for smart mirror

The 3-in-1 smart mirror laser engraving machine can perform surface marking, sandblasting, and back paint removal for the smart mirror. This is currently the most common model in the Chinese market.

6. 4-in-1 laser engraving machine for smart mirror

This 4-in-1 smart mirror laser engraving machine has an additional laser drilling technology compared to the 3-in-1.

It can complete laser marking, sandblasting, paint removal, and drilling on the same device, reducing downtime and conversion time. The seamless switching between different functions simplifies the operation process. It has advantages such as high integration, high efficiency, simple operation, and stable reliability. Suitable for large-scale production.

Advantages and disadvantages of smart mirror laser engraving machines

Advantages

1. Non-contact machining

Laser processing does not cause physical contact, resulting in minimal material loss and avoiding material fracture or damage, thus avoiding the problems of material wear and waste in traditional processing. Especially suitable for processing brittle materials, such as glass and ceramics.

2. Strong controllability

The smart mirror laser sandblasting machine can accurately adjust the laser’s power output. During processing, the laser parameters can be dynamically adjusted based on real-time feedback to adapt to different materials and processing needs, improving the flexibility and quality of processing.

3. Low loss

The smart mirror laser engraving machine reduces material loss and waste caused by wear and tear and does not produce a large amount of metal shavings or chemical waste. Compared with traditional mechanical processing equipment, laser sandblasting can usually complete the same processing task in a shorter time, thereby saving energy costs.

4. Customized services

The smart mirror laser sandblasting machine can achieve highly personalized processing patterns and designs according to customer requirements and design needs. Any texture or image can be created by removing the coating from the mirror, and the area where the coating is removed is like transparent glass. It can use lighting for backlighting, making it more attractive.

Disadvantages

1. High initial investment

The high initial investment is a significant disadvantage of smart mirror laser engraving machines in the market. As a high-tech equipment, its manufacturing cost and technical investment are relatively high. In addition to the purchase cost of the equipment itself, the regular maintenance and upkeep of components such as lasers, optical systems, and automation control systems further increases operating costs.

2. High technical requirements

There are indeed some challenges in terms of technical requirements for smart mirror laser sandblasting machines. Operators must be familiar with laser technology, CNC systems, material characteristics, and the adjustment and optimization of processing parameters, and have a rigorous work attitude and precise operating skills.

3. Material limitations

The smart mirror laser engraving machine has certain limitations in processing materials, which are mainly determined by its working principle and laser characteristics. For example, materials with high reflectivity or thermal conductivity (copper and aluminum) may reflect laser or dissipate heat too quickly, resulting in poor sandblasting effects.

4. Size limitations

Smart mirror laser engraving machines usually have a fixed processing area range. For larger workpieces, the laser beam’s processing range may not be fully covered, and the equipment’s workbench size is limited. For ultra-large workpieces, segmented processing may be required, increasing the process’s complexity.

Application fields of smart mirror laser engraving machines

What materials can it be used for?

Smart mirror laser engraving machine is an advanced equipment that can be applied to a variety of materials. According to the different glass materials, it can be divided into float glass, tempered glass and photovoltaic glass.

Float Glass

Tempered Glass

Photovoltaic Glass

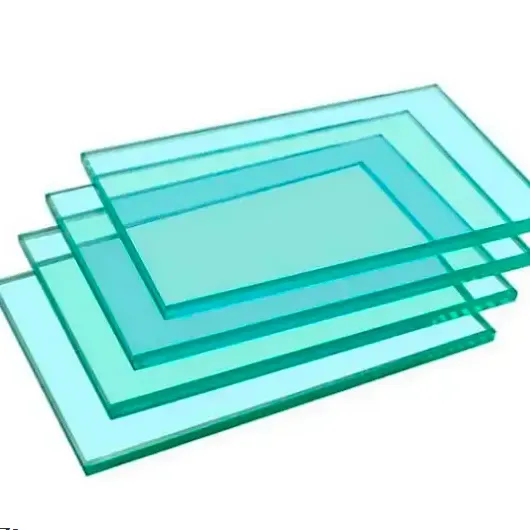

- Float glass is conventional glass with a flat surface, uniform thickness, and high transparency.

- Tempered glass has strong impact resistance and good heat resistance.

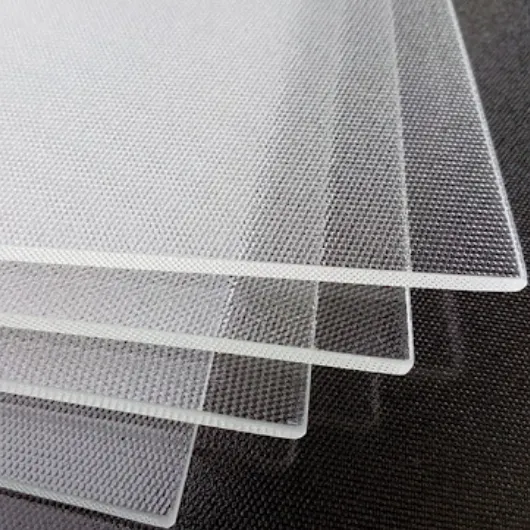

- Photovoltaic glass, also known as ultra white glass, is a type of silicate glass with low iron content, high transmittance, and good optical properties.

The smart mirror laser engraving machine has a wide range of applications and can be used to process the above three types of glass materials.

Also, the smart mirror laser marking machine can be applied to mirrors with various coatings such as silver, aluminum, indium tin oxide (ITO), aluminum oxide, silicon dioxide, and zinc oxide.

In summary, our smart mirror laser engraving machine can process float glass, tempered glass, and photovoltaic glass, and can be used on mirrors with a variety of coatings.

What industry can it be used for?

Smart mirror laser engraving machine has the advantages of high processing precision, high production efficiency, no pollution to the environment, etc., which can meet various complex shapes and personalized needs. It is widely used in glass industry, mirror industry, building manufacturing industry and smart home industry.

It is mainly used in the processing of smart mirrors and will become the preferred method for smart mirror processing.

HANTENCNC’s smart mirror laser engraving machines

The functions of 4-in-1 smart mirror laser engraving machine

Most smart mirror laser engraving machines on the market only have three functions: laser sandblasting, laser marking, and laser paint removal.

HANTENCNC has launched the HT6090 Pro+ high peak laser engraving machine, which is capable of performing multiple processes in one go, including mirror sandblasting, paint removal, glass drilling, and pattern marking.

Laser sandblasting

Laser marking

Laser removing paint

Laser drilling

Laser sandblasting

Smart mirror laser sandblasting utilizes a high-energy density laser beam to irradiate the glass surface. Control sandblasting time and intensity to produce a matte texture on the glass surface. Laser sandblasting can create various exquisite patterns and textures, achieving a mirror sanding effect. The sandblasting effect is delicate, with neat edges, no seams, and uniform and soft light transmission.

Laser marking

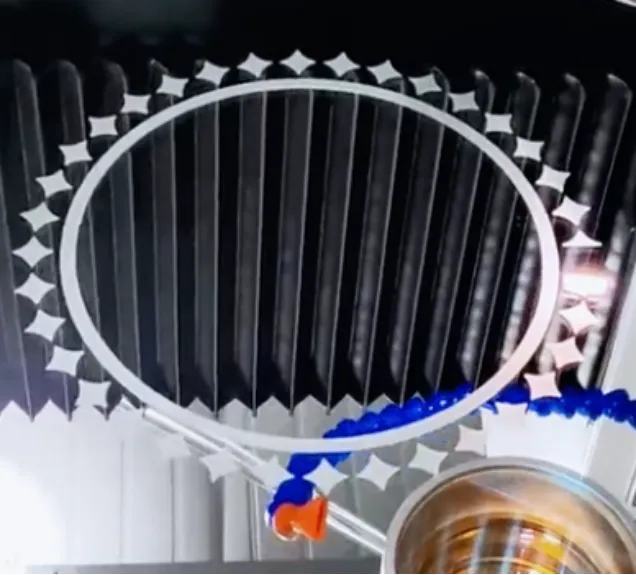

Laser marking can create exquisite patterns or geometric designs on the surface of smart mirrors, customize artistic patterns, perform functional labeling, promote slogans or brand stories, and increase brand communication channels.

Laser removing paint

Smart mirror laser paint stripping is an advanced surface treatment technology that achieves a clean and residue-free paint stripping effect, causing no damage to the mirror surface. The display area after laser paint removal can form one or more transparent areas due to the lack of coating obstruction.

Laser drilling

Smart mirror laser drilling can create decorative patterns and designs on the surface of the mirror, drill holes on the frame or edge of the mirror for wall installation and fixation, reserve installation holes for LED lights, and provide a backlighting function. The specific size and position of the hole can be adjusted as needed.

The HT6090 Pro+can not only drill circular holes in ordinary glass but also waist-shaped holes, irregular holes, square holes, etc. However, due to the lack of power following the speed function in current control, it cannot achieve cutting at right angles and sharp angles.

The price of smart mirror laser engraving machine

When choosing a smart mirror laser engraving machine, you may find that the prices of other brands on the market are dazzling and irregular. This is because of its functionality, which is the single function and multi-function mentioned above. The price of the product will naturally be different if the function is different, and the price will increase with the increase of functions.

Secondly, many brands will make a fuss about the price, pricing too low and adding hidden fees. But we promise that all prices are transparent and there are no hidden fees.

The price of 4-in-1 devices on the market is mostly around $49,999.00, which is expensive. The price of 3-in-1 is also around $36,450.19, and it lacks a drilling function and has limited functions. HANTENCNC’s 4-in-1 smart mirror laser engraving machine is not only powerful but also cheap. Not only can you save money, but you can also enjoy higher-cost performance and better service.

The price of HANTENCNC’s smart mirror laser engraving machine is $44117-$51470, which supports customization. You can choose different configurations according to your needs.

The features of smart mirror laser engraving machine

1. Efficient coating removal

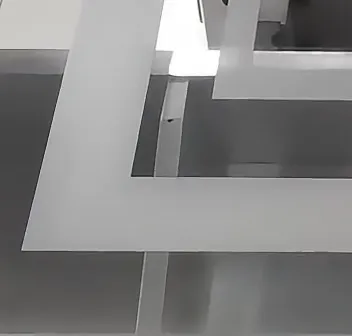

Our machine HT6090 adopts the latest four axis linkage control system. When the XY ammeter swings and emits light, the gantry drives the laser to move within the processing range, greatly improving the processing speed.

It can proficiently use 120kHz and 85% power to remove the coating on the back of the mirror, while maintaining the smoothness and integrity of the mirror surface.

2. High speed galvanometer system

The HT6090 galvanometer motor is designed as a dynamic magnetic structure and was developed using military grade technology and technological level. It has the characteristics of good stability, high positioning accuracy, fast marking speed, and strong anti-interference ability.

The machine uses a large 14-spot galvanometer to receive lasers in a wider range. The larger the incident laser spot, the finer the processed lines.

3. Advanced fiber laser technology

Our laser has the characteristics of high performance, strong stability, and resistance to high reflection. It has a wide range of applications, including glass drilling (Pro+large holes), surface treatment, laser cutting, laser marking, smart mirror paint stripping, and sandblasting.

4.Precision and safety integrated

Adopting high-performance control systems and software to achieve high-precision positioning. Integrating smart sensors and monitoring systems ensures the safe and stable operation of equipment while also protecting the safety of operators.

Smart mirror laser engraving machine technical parameters

| Model | HT6090 Pro+ |

| Laser Power | 120W |

| Central Wavelength | 1060-1080nm |

| Maximum Peak Power | >100KW |

| Power Turning Range | 0-100% |

| Frequency Turning Range | 1-3000KHZ |

| Laser Switching ON/OFF Time | <20μs |

| Pulse Width | 2-20ns |

| Beam Quality | M²<1.4 |

| Resist High Reaction | Yes |

| Indicator Red Light | 0.3-2MW |

| Collimated Beam Diameter | 10-12mm |

| Cooling Method | Water Cooling |

| Control Software | Own Research And Development |

| Scanning Galvanometer | =Φ14mm |

| Operating Temperature | 0-40 Degrees |

Buying considerations

When purchasing a smart mirror laser engraving machine, please ensure that the machine meets your requirements:

- Ensure that the machine can handle the materials you will be using, such as glass, mirrors, etc.

- Ensure that the power and intensity of the laser match your application requirements.

- Choose machines with a good market reputation and user feedback to ensure product quality and service.

- User friendly control system and interface, reducing operational complexity and improving work efficiency.

- Choose the equipment with the highest cost-effectiveness within the budget range.

About HANTENCNC

HANTENCNC is a company focused on the research and development, manufacturing, and sales of laser equipment, with an experienced engineering team and technical support team. We have over 19 years of professional knowledge in designing and manufacturing laser machines. Our products have obtained multiple certification certificates and have been exported to over 100 countries, providing multilingual support services. We are committed to collaborating with excellent partners from all over the world, with multiple agents on a global scale, to provide customers with localized sales support and technical services.

Our products include laser cleaning machines, welding machines, laser marking machines, laser cutting machines, and UV printers. You are welcome to contact us for more details or to arrange product demonstrations and consultations. We look forward to working with you!

Conclusion

With the rise of smart homes and personalized, customized products, the application of smart mirrors in home decoration, smart bathrooms, and commercial displays is becoming increasingly widespread, which has driven the rapid development of the smart mirror laser engraving machine market. As an advanced manufacturing equipment, the smart mirror laser engraving machine has broad development prospects, with multifunctional integrated design, sandblasting, marking, repainting, and drilling, achieving multi-purpose and significantly improving production efficiency.

Contact Us:

Whatsapp: +8613256727251

Email: [email protected]

Company Address: 402B, Building 16, Xingfu Liancheng Photoelectric Innovation Park, No. 1287, Kejia Road, Gaoxin Zone, Jinan City, Shandong Province, China