Advantages Of Color Laser Marking Machine

1. High quality imported galvanometer with high marking accuracy, fast speed, and strong anti-interference ability.

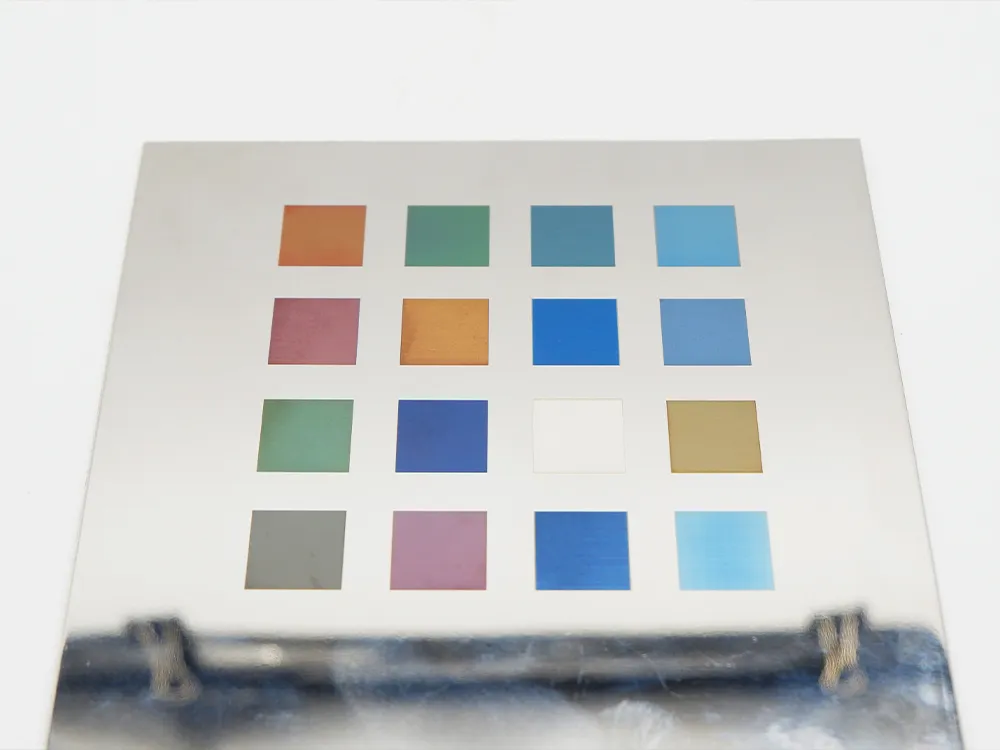

2. JPT MOPA laser, can be used for color marking on stainless steel and other metal surfaces.

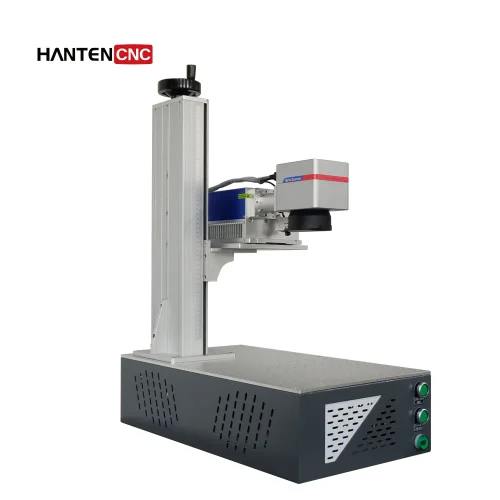

3. The color laser marking machine has a small size, light weight, and adopts a low-power design, which is energy-saving and environmentally friendly.

4. Adopting an air-cooled system, it can quickly control the temperature of the laser marking machine metal and maintain long-term stable operation of the equipment.

MOPA Color Laser Marking Machine Demonstration Video

MOPA Color Laser Marking Machine Display

MOPA Color Laser Marking Machine Component

MOPA Color Laser Marking Machine Dimensions

MOPA Color Laser Marking Machine Parameters

| Model | HTF-20 | HTF-30 | HTF-60 | HTF-100 |

| Net weight | 35kg | 35kg | 35kg | 35kg |

| Machine size | 350*600*830mm | 350*600*830mm | 350*600*830mm | 350*600*830mm |

Laser Parameters |

||||

| Power | 20W | 30W | 60W | 100W |

| Laser source | JPT/GZTECH | JPT/GZTECH | JPT/GZTECH | JPT/GZTECH |

| Marking area | 110-300mm | 110-300mm | 110-300mm | 110-300mm |

| Beam quality | <1.4m² | <1.4m² | <1.5m² | <1.6m² |

| Average output power | >20W | >30W | >60W | >100W |

| Power consumption | <110W | <150W | <330W | <440W |

| Central wavelength | 1064nm | 1064nm | 1064nm | 1064nm |

| Supply DC voltage (VDC) | 24V | 24V | 24V | 24V |

| Beam diameter | 7±0.5mm | 7±0.5mm | 7±0.5mm | 7±0.5mm |

| Cooling method | Air cooled | Air cooled | Air cooled | Air cooled |

MOPA Color Laser Marking Machine Details

High Quality Lens

The MOPA color laser marking machine adopts high transparency lenses, with low laser loss and precise CNC machining of the casing, which can achieve very high processing accuracy.

Our marking lens design focuses on efficiency and stability, accurately controlling laser energy and marking parameters to maintain consistent marking effects during long-term operation.

Manual Lifting Column

The manual lifting column design is simple and intuitive to operate, and the height can be adjusted by simply rotating or pulling the handle; No need for electric drive, avoiding the risk of faults that electric systems may bring.

Compared to electric lifting systems, manual lifting columns have lower manufacturing and maintenance costs, are environmentally friendly, energy-saving, and convenient to maintain.

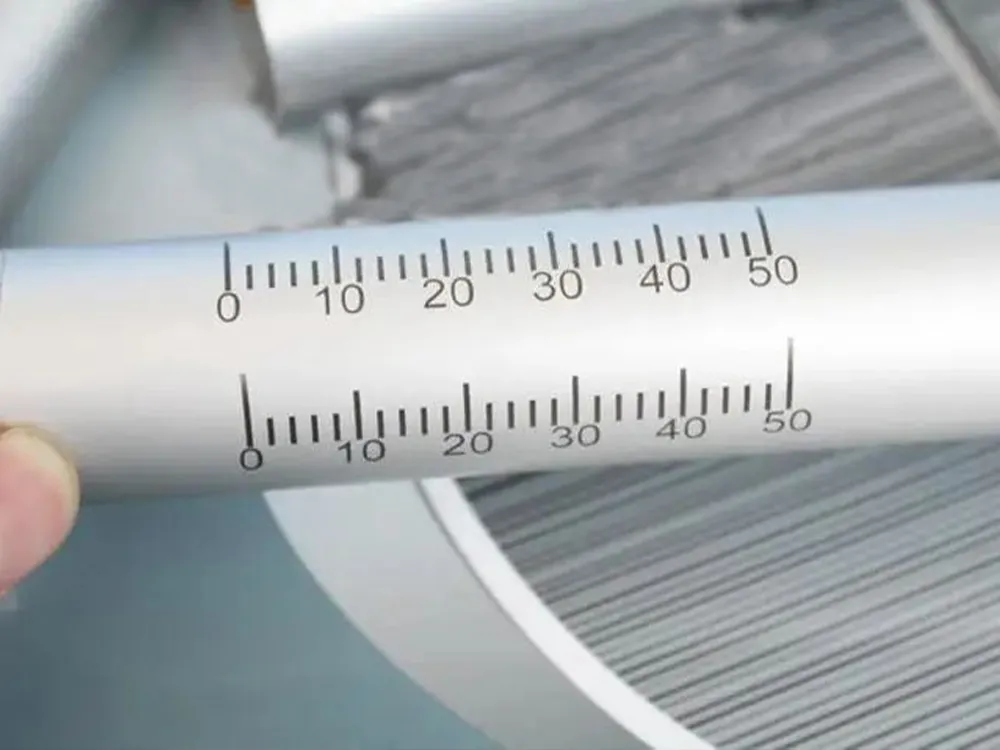

Graduated Lifting Column

The lifting column of the color laser marking machine is usually made of high-quality materials and precision processing technology. You can precisely adjust the height of the laser head by reading the scale, which improves operational efficiency.

The laser marking machine metal equipped with a graduated lifting column can provide high-quality and high-precision marking effects, improving the overall quality of the product.

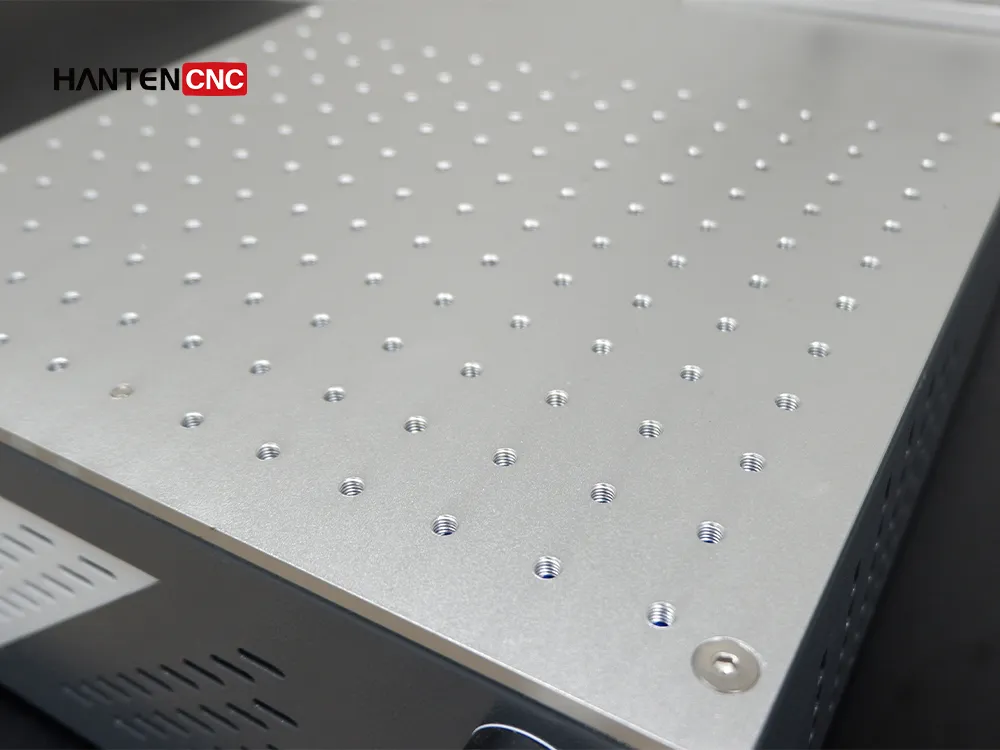

Aluminum Material Workbench

Aluminum material has good vibration resistance, which can effectively reduce the vibration that may occur during the laser marking process, ensuring the stability and accuracy of the marking process.

Aluminum material has strong durability, good wear resistance, smooth appearance, is not easy to accumulate dust and dirt, and is easy to clean and maintain.

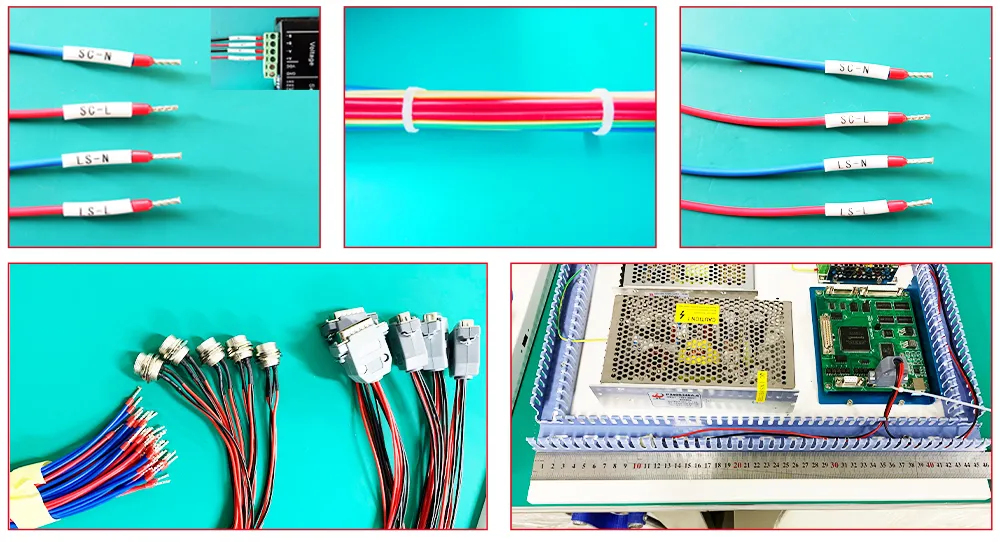

Well-organized Internal Wiring

The organized wiring of HANTENCNC’s color laser marking machine not only facilitates later maintenance, but also reduces the risk of electrical short circuits or malfunctions.

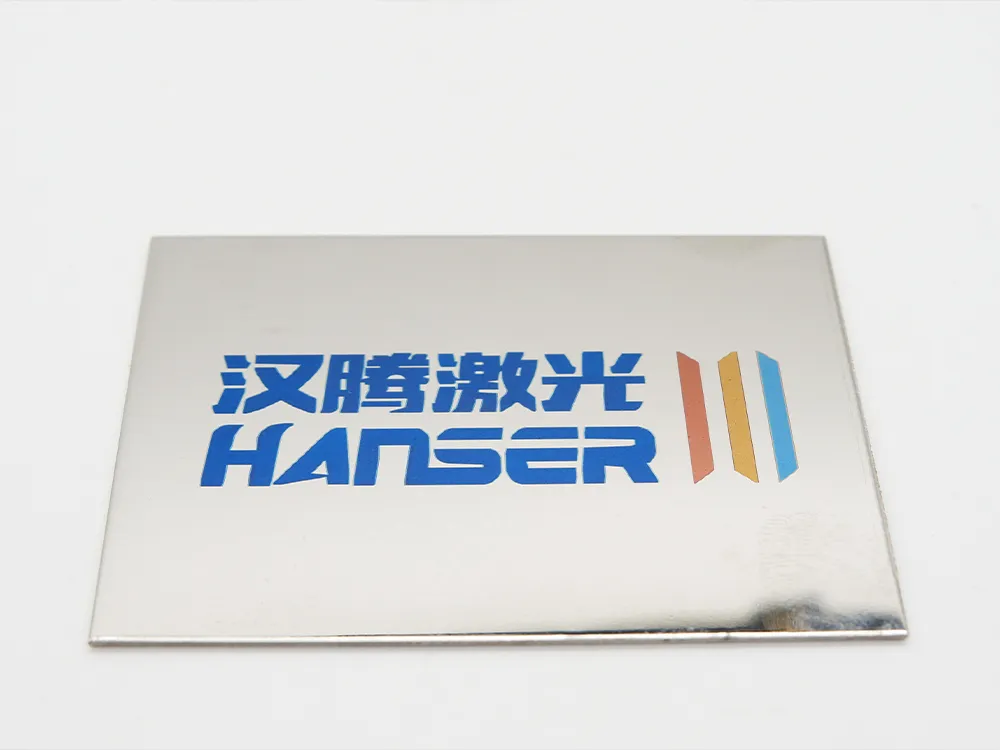

MOPA Color Laser Marking Machine Sample Display

The Jeep MOPA color laser marking machine can be used for marking metals (such as stainless steel, aluminum, copper), plastics (such as ABS, PC, PE), etc.

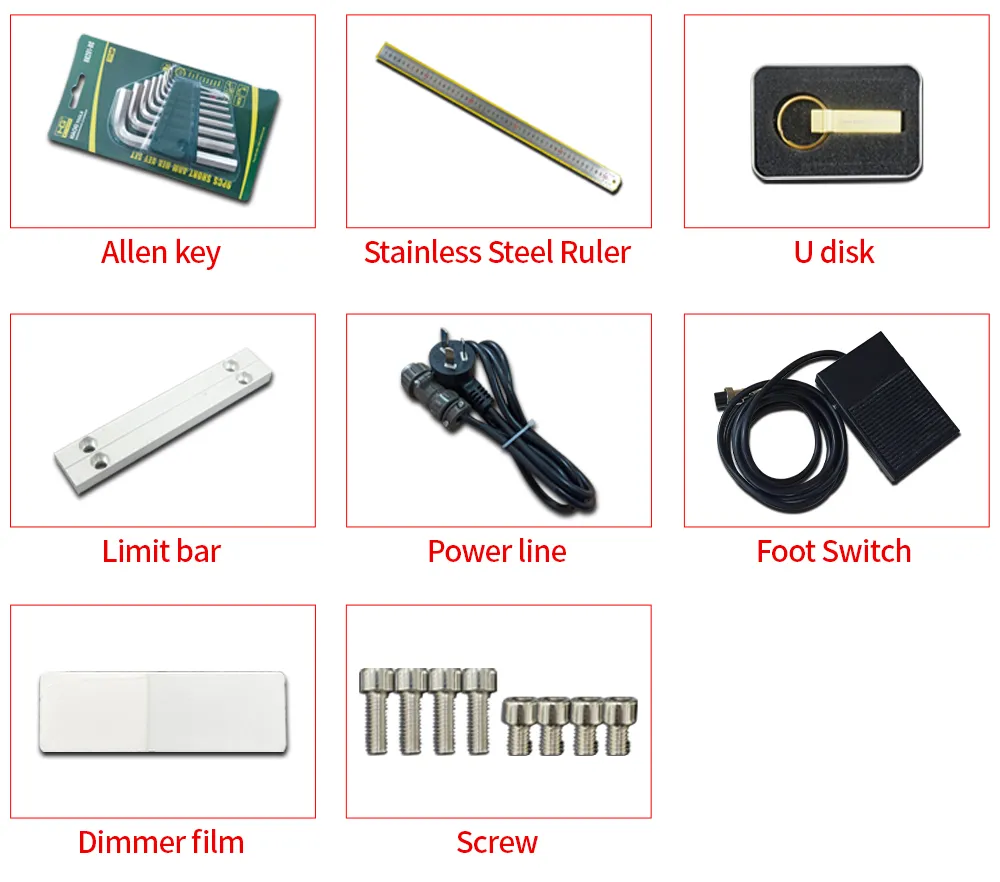

MOPA Color Laser Marking Machine Included Accessories

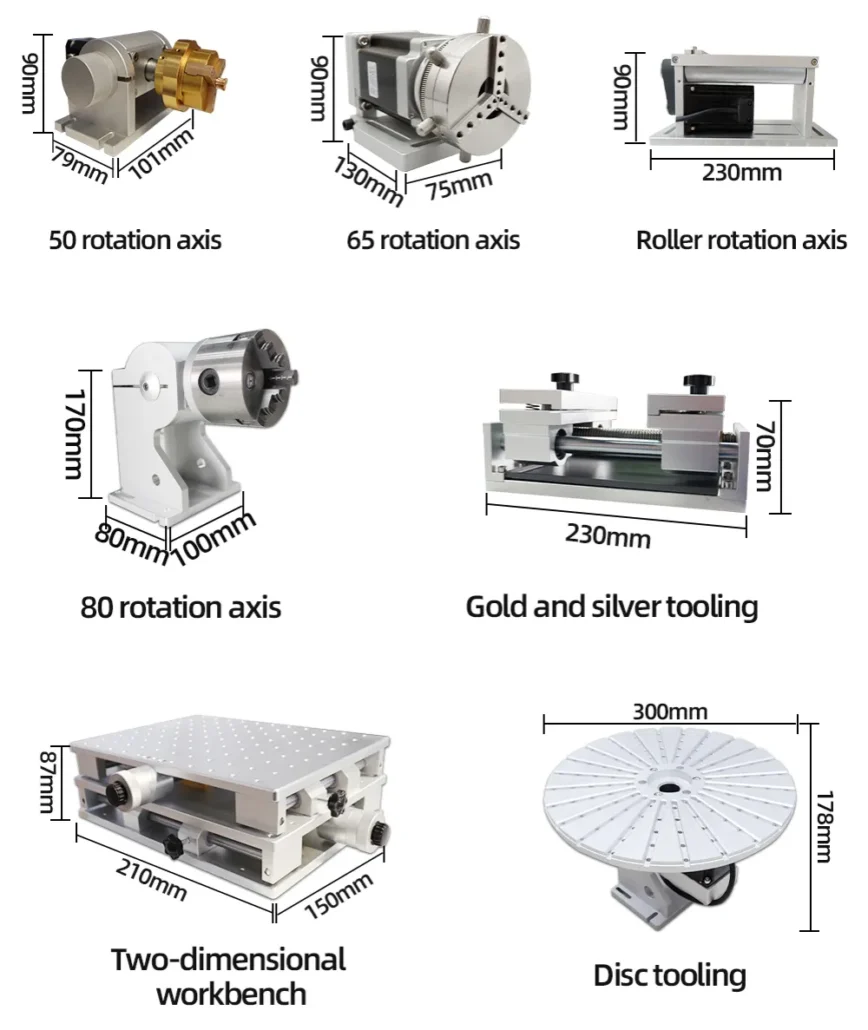

MOPA Color Laser Marking Machine Accessory Selection

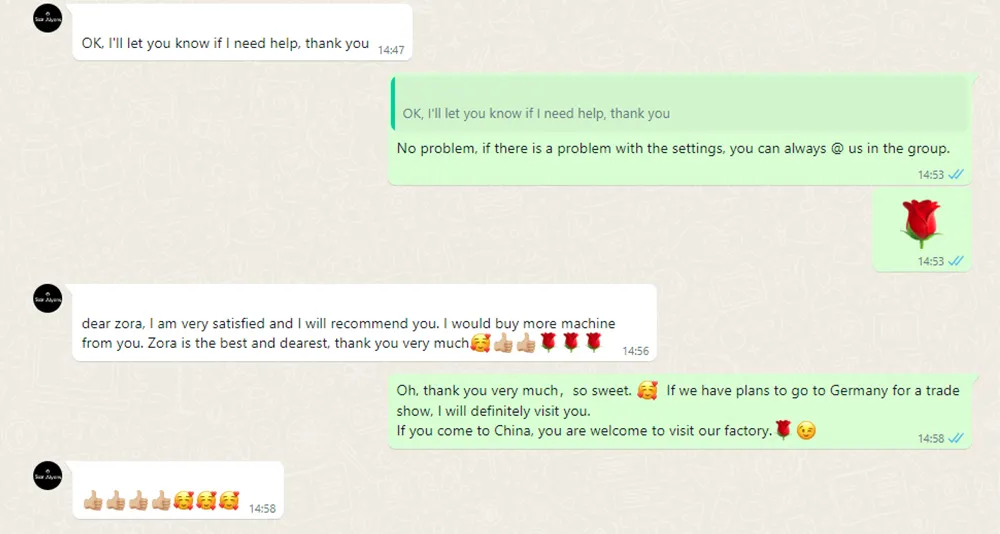

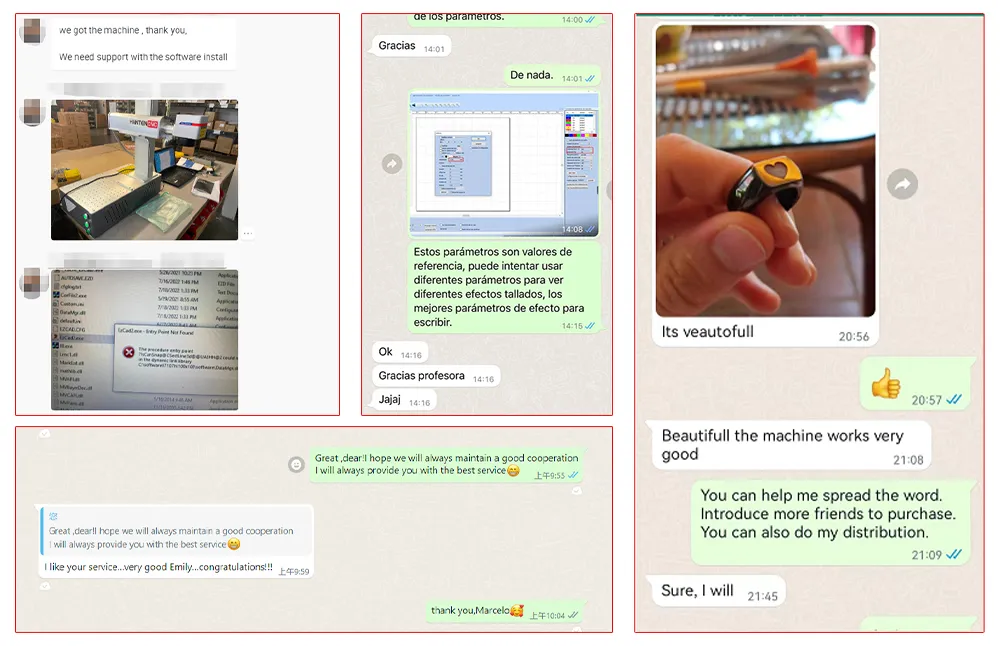

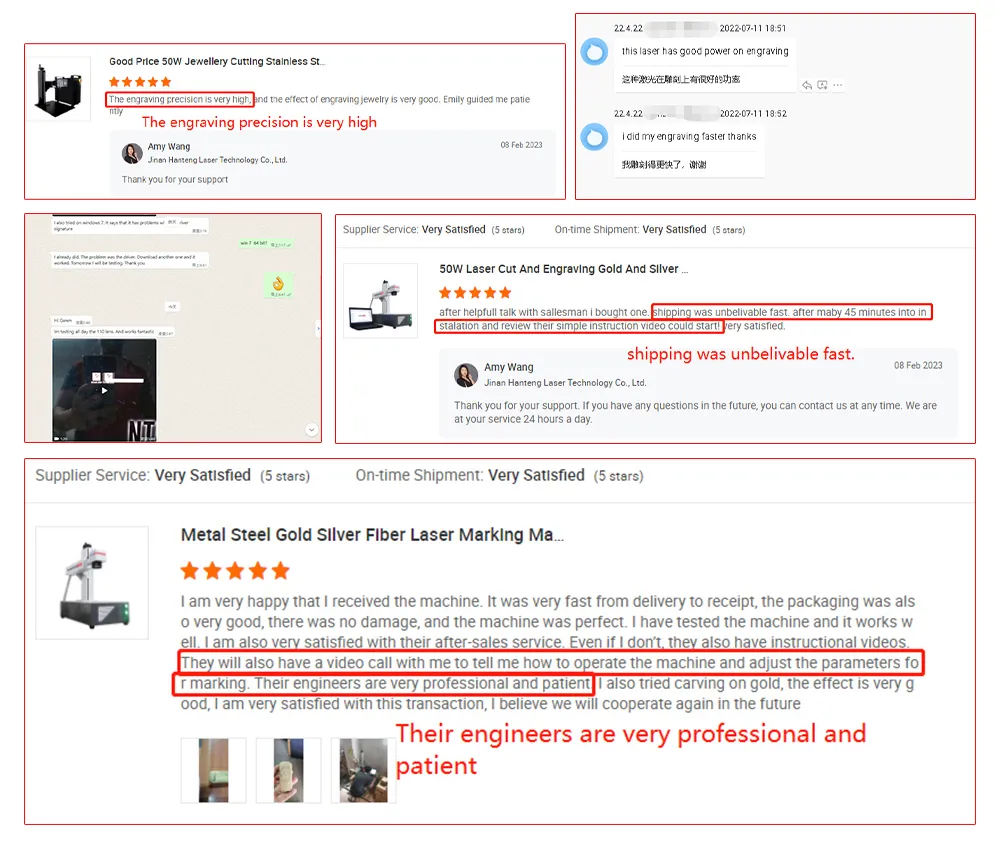

Customer Reviews

Customer Visits

Qualification Certifications

HANTENCNC Partnerships