Modern social science and technology have developed rapidly. Unprecedented progress has been made in manipulating image patterns. UV printing came into being to meet users’ needs and give full play to designers’ creative talents. With time, UV print has continuously upgraded and matured. Many friends have been holding a wait-and-see attitude because they are unfamiliar with UV printing. Don’t worry. This article shows you all about UV printing.

What is UV Printing

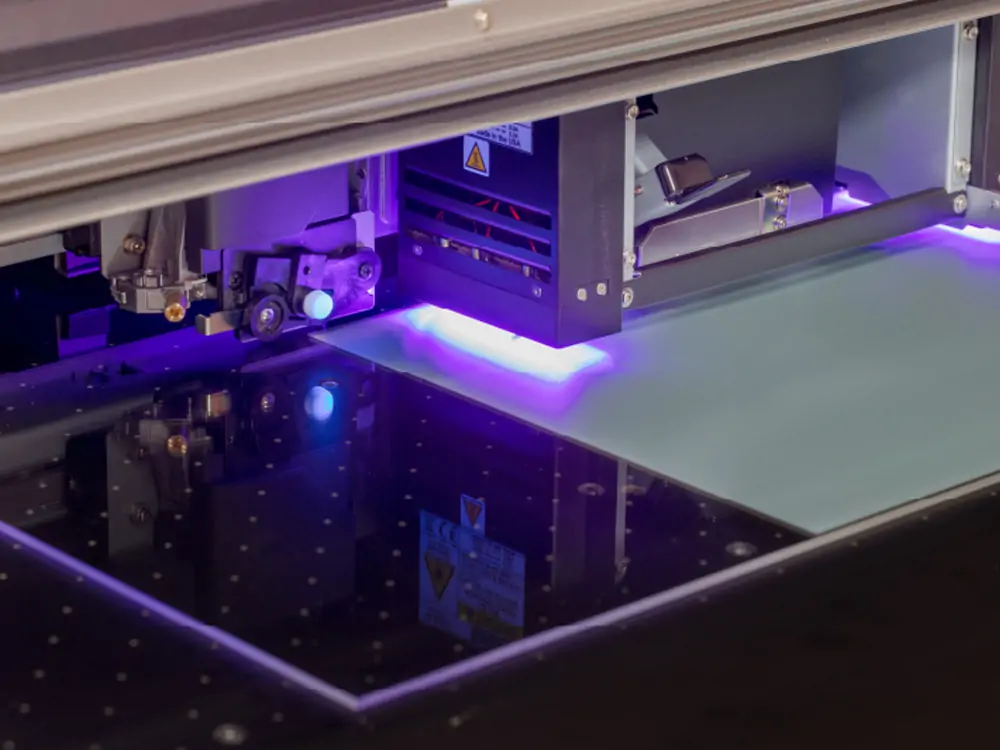

Unlike traditional printers, UV printing uses UV ink, hence the name. The printer is equipped with a UV lamp, which allows sampling of the printed pattern immediately after printing. This feature makes production and proofing very convenient to a large extent. With personalized production methods, UV printing also brings convenience to the processing industry. UV printers can achieve high-precision and high-speed printing, and the accuracy is optional. The working principle of UV printing is that one nozzle is responsible for one color. At least four basic colors of C, K, M, and Y can be used to spray out beautiful patterns.

In simple terms, UV printing is ultraviolet curing printing. Essentially, it is a type of piezoelectric inkjet printing. The effect of concave and convex can be achieved through UV ink printing. Compared with ordinary printing, UV printing has no restrictions on products and materials. UV printing does not require plate making and can realize personalized custom printing according to needs.

Features of UV Printing

- Easy to Use

A computer controls the UV printer. After setting the parameters on the computer, it can be printed automatically. A lot of labor is saved.

- Pollution Reduction

Although the smell of UV ink is also relatively unpleasant, compared with weak solvents, the pungent smell of silk screen printing dramatically reduces pollution. Moreover, the printing process will not generate noise. The whole production process is green and pollution-free.

- Does not contain volatile organic solvents VOC

UV ink is green and environmentally friendly. It cures quickly and is VOC-free.

- Durable

- Rich in Color

- Anti-UV

- Print Images Fast

- Low Energy Consumption

- Efficient

- Wide Range of Applications

Applications of UV Inkjet Printing

UV printers can print a variety of materials. Therefore, a UV printer is also called a universal printer. Following are the industries where UV ink printers can be used.

Applications in Art

Due to the nature of UV printing, it can be applied to art in many ways. The UV printer can print any flat material. It liberates productivity from the previous manual inkjet process and realizes mechanized production.

Application in The Decoration Industry

UV printing plays a vital role in the art field but also significantly influences the decoration industry. The computer completely controls the UV output pattern of UV machine printing. It is this feature that UV printing machines quickly opened up the market in the field of decoration. UV ink printing perfectly suits flat materials such as glass sliding doors, ceramic tiles, carpets, and wood boards. UV machine printing can personalize any interior or exterior building.

Application in Advertising Industry

The appearance of UV printers has brought excellent changes to the advertising industry. In the past, advertising generally used traditional techniques. The problem of small batches and high costs still needs to be resolved. Even thermal transfer printing requires a temperature range that the material can withstand. The UV printing machine prints in a single piece, and the LED is a cold light source suitable for any flat material.

The Working Principle of UV Printer

UV printers are also called UV flatbed printers, UV inkjet printers, universal printers, etc. Below, we will show you how the UV printed machine works.

Printing Principle

UV printers use piezoelectric inkjet printing technology. It does not directly contact the material’s surface but relies on the voltage inside the printhead. The ink in the nozzle hole is sprayed onto the surface of the substrate to achieve the purpose of printing the picture. The nozzle plays a crucial role. Generally, there are thousands of nozzle holes on a small nozzle. These orifices are challenging to see with the naked eye. The nozzle can precisely control the ink output from the nozzle hole.

Solidification Principle

The ultraviolet light emitted by the LED cold light source reacts with the photosensitive curing agent in the UV ink. The pigment molecules in the UV ink are cured on the material’s surface. Thereby realizing the drying of ink. Past printing equipment required baking, drying, and other processes. The UV printed machine is entirely different from previous printing equipment. It increases productivity while reducing unnecessary equipment and personnel expenses.

Positioning Principle

The UV printer can precisely control the equipment to print patterns on different materials, volumes, heights, and shapes. The positioning of the X-axis mainly depends on the raster decoder to direct the horizontal printing of the equipment. On the Y axis, the length of the printing material is mainly controlled by the drive of the servo motor. Height positioning primarily depends on the lifting function of the machine head.

Future of UV Printing

Most people are very concerned about this issue. The prospect of UV ink printing is up-and-coming. UV-printed machines have been developed for more than ten years. And UV flatbed printer is widely used. Secondly, the flatbed UV printer has a few limitations. There are few restrictions, whether it is the field technicians or the scale to develop the business. UV-printed machines are simple, flexible, low-cost, and high-return, allowing rapid development and continuous continuation.

How to Choose The Best UV Printer

Many friends think that choosing affordable UV printers is a straightforward matter. But that is not the case. UV printers are widely used, and the market demand is enormous. If you plan to buy UV machine printing, you should continue reading.

Meet Your Own Needs

Consider your capital budget, the production scale of your factory, and your business type.

Reliable UV Printer Manufacturer

First, you can find the manufacturer’s information online and understand the supplier’s reputation. Secondly, it is recommended to visit the manufacturer on-site to check the manufacturer’s production scale, technical team, and service attitude. Third, go to the manufacturer’s site for field testing and proofing and observe the equipment’s control system and the price of the fuselage. Fourth, ask for a price. Be sure to meet your budget on the premise of ensuring quality. Finally, ask after sales. Find out how the service team of UV flatbed printer manufacturers is configured and whether they can answer questions promptly.

Conclusion

When we learn more about UV inkjet printing, we find that it is not just a printing method but a catalyst that pushes the boundaries of creativity and design. The emergence of UV printing has brought new possibilities to all walks of life. Its applications are everywhere, from the packaging industry to interior decoration to the field of personalization.

Through this article, you already have enough understanding of UV printing. UV printing is one of the most popular printing methods today. HANTENCNC has sufficient expertise in UV printing. If you have any questions about UV flatbed printing, please get in touch with us in time. At the same time, we also have advanced UV flatbed printers. Feel free to contact us if needed.