What is a galvo laser welding machine?

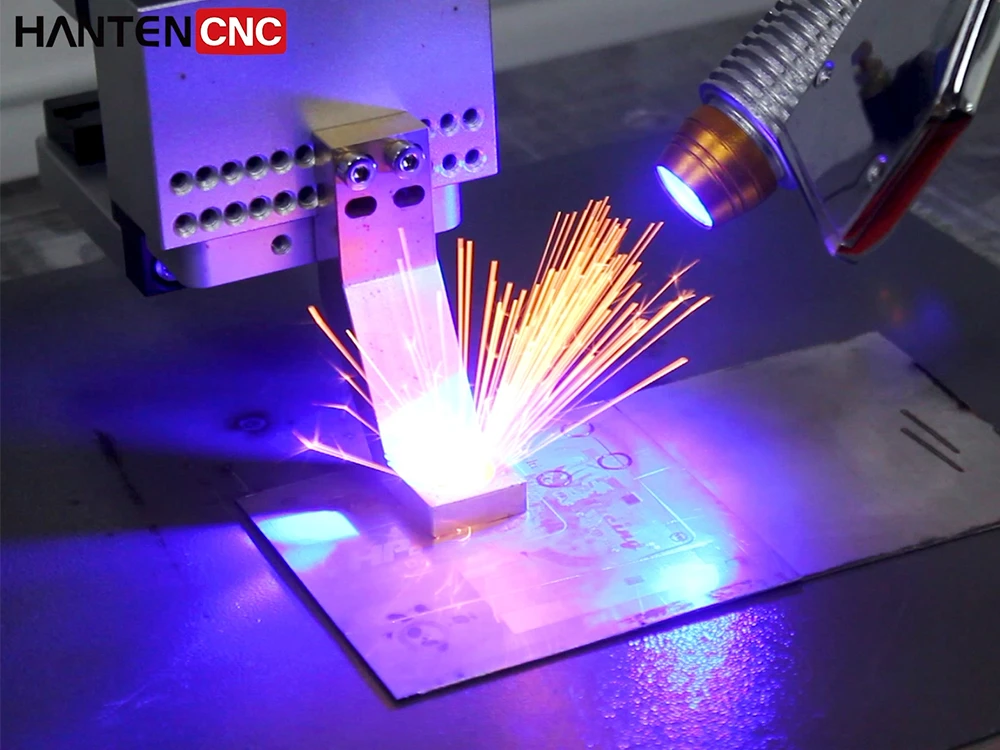

Before understanding the application of the galvanometer laser welding machine, many people will ask, what is the galvanometer laser welding machine? It is a high-precision welding equipment that can be used for metal material processing. It can precisely weld metal materials together to ensure welding quality.

The principle of the galvanometer laser welding machine: First, the laser source will generate a beam of intense laser light. The laser beam passes through a galvanometer system and is then focused onto the metal material, which is burned by the laser. When the laser heats up to a certain temperature, the two metal materials fuse together. Form a complete weld.

The galvanometer laser welding machine is like a magical hand with magical abilities. It seamlessly “glues” two pieces of metal together. The galvanometer laser welding machine is a major breakthrough in the development of welding technology today. Improve our product quality and make our life more convenient.

Advantages and disadvantages of galvanometer laser welding machine

Advantages of galvanometer laser welding machine

So compared with ordinary welding methods, what are the advantages of the galvanometer laser welding machine? Take a look at the galvanometer welding machine of Hanteng CNC, it has the following advantages:

- High precision:

Galvanometer technology enables high-precision laser welding. The accuracy of solder joints can reach 0.1mm. - High speed:

The galvanometer laser welding machine adopts high-speed galvanometer scanning. High-speed welding can be realized, and the production efficiency is many times higher than that of traditional welding methods. - High efficiency:

The laser beam of the vibrating mirror laser welding machine is directly irradiated on the surface of the workpiece for welding. Greatly improved welding efficiency. - Low temperature deformation:

Laser welding can concentrate energy, weld quickly and reduce heat input. Thereby reducing temperature deformation and ensuring welding quality. - Various materials can be welded:

Laser welding can weld various metals and their alloy materials. It is also possible to weld non-metallic materials by adjusting the laser power. - Environmental protection and energy saving:

Laser welding does not require the use of flux, which reduces environmental pollution and saves energy.

In summary, it can be seen that the vibrating mirror laser welding machine not only saves time and effort, but also has high efficiency. It is a rare welding tool. If you have welding equipment like HANTENCNC, I believe it can save you a lot of cost and time.

The galvanometer laser welding machine also has the following disadvantages

- Suitable for large-scale production:

The galvanometer laser welding machine is more expensive. Compared with automatic welding methods such as manual welding, it is more suitable for large-scale production and mass production. It may not be the most economical option for small to medium batch production. - High environmental requirements:

The beam produced by the laser will have a certain impact on the environment. Special fire protection measures and protective equipment are required. - The impact of laser glare on human eyes:

The glare generated by the laser is harmful to the human body, and protective measures must be taken. Workers need to wear protective glasses and other protective equipment. - High requirements on the surface of the workpiece:

Laser welding requires a certain reflective surface of the material. There should be no defects such as oxide layer. If the surface quality of the workpiece is not good, it will affect the quality of laser welding.

HANTENCNC engineers remind you:

Although the galvanometer laser welding machine has many advantages. However, the above disadvantages need to be considered in actual use. And the requirements of laser welding on material processing, circuit design, energy consumption, etc. To ensure its efficient and stable operation.

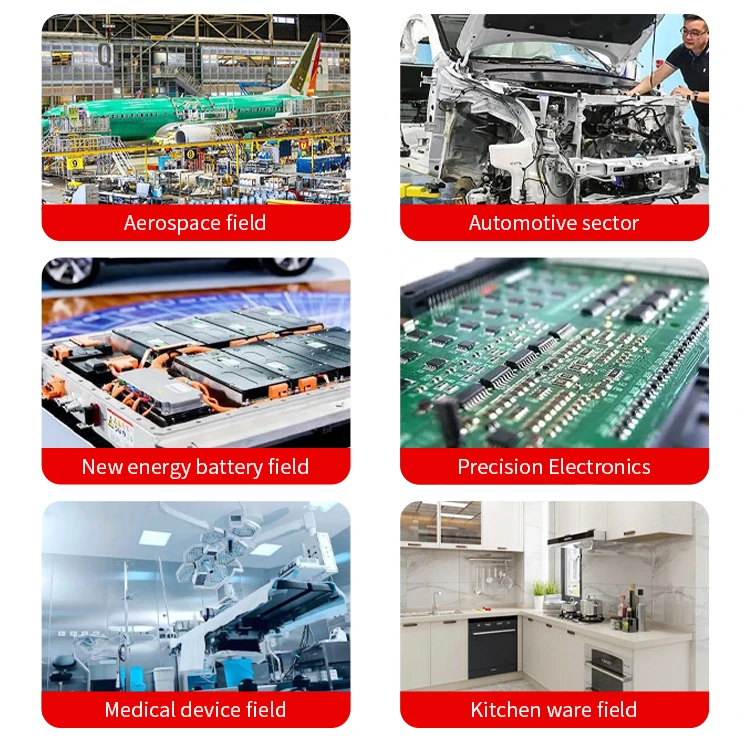

Application industry of galvanometer laser welding machine

The vibrating mirror laser welding machine has the advantages of high efficiency and high precision. Therefore, it is widely used in many industries, including but not limited to the following fields:

- Automobile manufacturing industry:

Such as car wheels, body welding, etc. - Electronic manufacturing industry:

Welding of stainless steel shells, battery covers and other smart phones, TVs and other product components. - Metal manufacturing industry:

Such as welding and repairing of metal parts in aerospace, machinery manufacturing and other fields. - Medical device manufacturing industry:

Welding of stainless steel parts for dental instruments, scalpels and other products. - Household appliance manufacturing industry:

Welding of kitchen and bathroom equipment, stainless steel stove, gas stove and other products. - Aluminum alloy product manufacturing industry:

Such as aviation aluminum alloy parts, sports equipment and other products welding. - New energy industry:

Connector welding, lug welding, soft package series welding, clamshell welding, spot welding, cover plate welding, sealing nail welding, pole welding. - Hardware industry:

Radiator welding, water-cooled air-cooled edge welding. - Kitchen and bathroom industry, home appliance industry, stainless steel doors and windows, advertising industry, mold industry, etc.

In short, galvanometer laser welding machines are widely used in many industries. It can improve production efficiency and reduce costs. At the same time, it also provides a guarantee for product quality. If you have such a device, you can use it not only in your own industry. It can also be rented to other industries, which is also a very cost-effective way.

Purchasing a galvanometer laser welding machine can bring the following benefits

- Efficient production:

The galvanometer laser welding machine uses laser technology. It can complete high-quality welding work in a short time and improve production efficiency. - Excellent welding quality:

Laser welding can reduce heat input, thereby reducing deformation and stress on the workpiece. The surface precision of the welding workpiece is high. No uneven defects. - Extremely high precision and stability:

The laser beam can position the solder joints very precisely. The galvanometer controls the laser beam to confine the solder joints to within a few hundred microns. Make welding more accurate, stable and reliable. - Handling multiple materials:

Laser welding machines can weld a variety of materials. Such as steel, copper, aluminum, zinc and other materials. With greater flexibility. - Environmental protection and safety:

During the laser welding process, no chemical substances are emitted. Can reduce environmental pollution and occupational health risks. - Save time and effort:

Laser welding requires only a few people to operate. Greatly save labor cost and time cost.

If you need efficient, high-precision, high-quality welding solutions. Then the galvanometer laser welding machine of HANTENCNC is a good choice. Especially for enterprises that produce in large quantities or require intensive welding, and have high requirements on cost and production efficiency. Purchasing a galvo laser welding machine can increase productivity and profit levels. If necessary, you can contact online customers at any time. HANTENCNC is willing to provide you with the best quality service.

There are essential differences between ordinary welding machines and galvanometer laser welding machines in the welding process. There is also a big difference in performance.

For example, the welding accuracy of ordinary welding machines can only reach the millimeter level. The welding accuracy of the galvanometer laser welding machine can reach the micron level.

In addition, the welding speed of ordinary welding machines can only reach the general level. The welding speed of the galvanometer laser welding machine can reach extremely fast. The speed of the former is like jogging, and the speed of the latter is like a rocket.

For another example, the welding quality of ordinary welding machines can only reach a moderate level. The welding quality of the galvanometer laser welding machine can reach a very high level. The quality of the former is like an ordinary car, and the quality of the latter is like a luxury car.

In short, the galvanometer laser welding machine has stronger advantages than ordinary welding machines in terms of welding accuracy, welding speed, and welding quality. It can be said that it is ten times or a hundred times that of ordinary welding machines. It can be seen that the appearance of the galvanometer laser welding machine has undoubtedly greatly improved the level of welding technology. It has brought great convenience to our work.