Laser welding machine is a high-tech welding equipment widely used in manufacturing and industrial production. It plays an important role in modern industrial production. HANTENCNC laser welding technology has the following advantages:Efficient,High precision,High quality,Environmental protection, etc.

HANTENCNC will introduce the laser welding machine in detail in this article. Including its structural performance, specific application, operation and use.

Laser welding machine details

Machine structure

The structure of the laser welding machine mainly includes laser generator, beam transmission system, welding head, control system and other parts. Each part will be described in detail below.

- Laser generator

The laser generator is the core component of the laser welding machine. It is mainly composed of laser tubes, mirrors, pump sources and other parts. The laser tube is filled with a laser medium, and when electrified, the atoms or molecules in the laser medium will be excited to emit photons, thus forming a laser beam. Mirrors reflect the laser beam into the beam delivery system. The pump source is mainly used to provide energy to excite atoms or molecules in the laser medium.

- Beam delivery system

The beam delivery system is the device that transmits the laser beam from the laser generator to the welding head. The beam transmission system is mainly composed of laser beam guide rails, mirrors, lenses and so on. It can precisely control the transmission path and spot size of the laser beam to meet the needs of different welding tasks.

- Welding head

The welding head is the part that focuses the laser beam onto the welding point. It usually consists of lenses, mirrors, cooling systems, etc. The welding head is able to focus the laser beam to a very small spot, enabling high-precision welding.

- Control system

The control system is the brain of the laser welding machine, which can control the movement and operation of the laser generator, the beam transmission system, the welding head, the workpiece clamping device and other components. The control system usually consists of computers, controllers, sensors, etc. It can realize the functions of welding parameter setting, data collection and analysis, system fault diagnosis and so on.

Machine parameters

| Model | HTW1000/1500/2000/3000 |

|---|---|

| Laser wavelength | 1080nm |

| Fiber length | 10M/Maximum 15M |

| Operating Mode | Continuous Welding |

| Speed range | 0-120mm/s |

| Laser power | 1000W/1500W/2000W/3000W |

| Operating System | Handheld Welding System |

| Cooling water chiller | Industrial chiller |

| Working environment temperature range | 15-35℃ |

| Humidity range Operating environment | < 70% non-condensing |

| Welding gap requirements | ≤0.5mm |

| Working voltage | 1000W-2000W is 220V/2P 3000W is 380V/3P |

Understand the function of laser welding machine

Application industry

A laser welding machine is a device that uses a laser beam to weld two or more metal pieces together. It is a device that uses laser beams for welding, and its high energy density and high welding speed make it widely used in many industries. The following are the common application industries of HANTENCNC laser welding machine:

- Automobile manufacturing industry: Laser welding machines are widely used in automobile production lines. Such as welding body, chassis and engine components. It can effectively improve welding speed and quality, reduce cost and waste.

- Electronics industry: Laser welding machines are used for welding electronic components. Such as mobile phones, computers, TVs, digital cameras, etc. Can effectively improve production efficiency and product quality.

- Aerospace industry: Laser welding machines are used to produce aerospace components such as engines, wings and suspension systems. Can effectively improve product quality and production efficiency.

- Metal manufacturing industry: Laser welding machines are widely used in the field of metal processing. Includes welding of metal pipe, steel, aluminum and copper.

- Medical device industry: Laser welding machines are used to produce medical devices. Such as surgical instruments, dental instruments, artificial joints and implants, etc. It can effectively improve the precision and quality of the product.

Machine function

- Welding

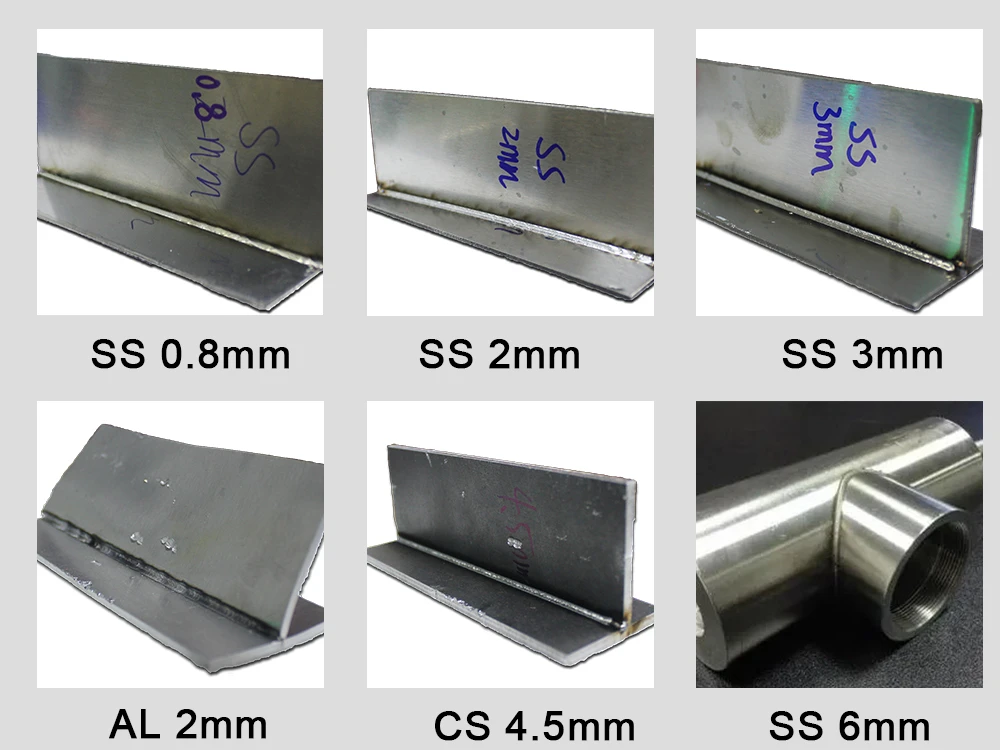

The primary use of a laser welding machine is undoubtedly welding. It can not only weld thin-walled metal materials such as stainless steel plate, aluminum plate, galvanized plate, etc., but also can be used for welding sheet metal parts.

- Such as kitchen utensils, suitable for welding of any shape such as plane, straight line, and arc.

- Widely used in precision machinery. Such as: jewelry, electronic components, batteries, watches, communications, handicrafts and other industries.

Laser welding machines can weld well in various complex environments. High production efficiency, compared with traditional argon arc welding, electric welding and other processes, it has more obvious advantages.

Using laser welding machine, the weld width is small, the depth is large, the thermal shock area is small, and the deformation is small. The welding seam is smooth and beautiful, and the welding quality is high. No porosity, accurate control, stable welding quality, no need to deal with or simple treatment after welding.

- Repair

The use of the laser welding machine is not limited to welding, but also to repair the wear, defect, scratch of the mold, and the sand hole, crack, deformation and other defects of the metal workpiece.

The mold will wear out after a long time of use. If it is directly discarded, the loss will be large. The problematic mold can be fully utilized again by repairing the problematic mold through the laser welding machine, especially when repairing the fine surface, avoiding the two problems of thermal strain and post-welding treatment. One process, greatly saving production time and production costs.

- Cutting

Laser cutting is a new cutting method. Materials such as stainless steel, copper, aluminum, zirconium and their alloys can be cut by using a laser welding machine.

In addition, it can also cut plastic, rubber, wood and other non-metallic materials. It is another important application of laser welding machine in material processing.

- Clean

With the continuous reform and upgrading of laser welding machines, there are more and more functions. Not only for welding and cutting, but also for cleaning and rust removal. Cleaning with a laser welding machine has the characteristics of non-contact, does not require cleaning fluid, and can replace professional cleaning equipment.

What are the advantages of laser welding?

- High precision: The fiber laser welding machine uses high-energy-density laser beams, which can perform precise welding at the micron level, ensuring the accuracy and quality of the welding parts.

- High efficiency: The speed of the fiber laser welding machine is fast, and it can complete a large amount of welding work in a short time to improve production efficiency.

- High stability: The fiber laser welding machine can maintain a stable working state in different working environments, and is not affected by factors such as ambient temperature, humidity, and air pressure.

- Energy saving and environmental protection: The fiber laser welding machine adopts high-efficiency fiber laser, which can save energy and will not produce waste gas, waste water and other pollutants. It is an environmentally friendly welding equipment.

- Versatility: The fiber laser welding machine is capable of welding different materials, such as metal, plastic, ceramics, etc., and has a wide range of application fields.

Are laser welded products strong?

Laser welding can be very strong, depending mainly on the type of material being welded, the quality of the welding process and the skill level of the operator.

Laser welding is a high energy density welding method. By focusing the laser beam on the material to be welded, it melts instantly and forms a weld. Due to the low heat input of laser welding, overheating and deformation can be avoided, while also maintaining high welding speed and small heat-affected zone.

This makes laser welding very popular in many fields, including automotive manufacturing, aerospace, electronics manufacturing, and more. In these fields, welded joints need to withstand high-intensity forces and vibrations, so the welding quality and strength of laser welding are particularly important. Laser welding can achieve very strong welded joints if the welding process and quality control are done properly.

Is the laser welding machine easy to operate?

The operation of the laser welding machine requires certain skills and experience. But compared with the traditional manual welding method, its operation is relatively simple.Operating a laser welding machine requires the following steps:

- Preparatory work: First of all, a safety inspection must be carried out, and the equipment must be correctly set and calibrated.

- Debugging equipment: It is necessary to debug the equipment according to different welding tasks. Such as setting laser power, welding speed, welding distance and other parameters.

- Position the workpiece: fix the workpiece to be welded on the workbench of the equipment. And make sure that the positioning of the welding area is accurate.

- Start welding: The operator starts the laser beam through the control panel or computer software. Focus it on the weld area to weld.

Overall, the operation of laser welding machines is simpler than traditional manual welding methods. Because it can not only control the welding process through computer programs or automatic control. It can also reduce the difficulty and risk of manual operation. However, certain expertise and skills are required. For example, understand the nature and characteristics of lasers, and master the operation skills of equipment.