Company Profile

HANTENCNC is a national high-tech enterprise specializing in the following fields:

1. Laser cleaning,

2. Laser marking,

3. Laser cutting

4. Laser welding equipment.

HANTENCNC integrates R&D, production, sales and service, the company is located in Jinan City, the capital of Shandong Province. The company adheres to the core mission of “born for quality”, provides customers with high-quality and reliable products, perfect solutions, fast after-sales service, and creating value for customers is the constant pursuit of HANTENCNC.

Laser cleaning machines have a variety of applications in different industries, including:

- Manufacturing:

Laser cleaning machines are used to clean different types of industrial materials such as: metals, ceramics, plastics and composites.They effectively remove rust, oil, dirt and other contaminants from the surface of these materials without damaging them. - Aerospace:

Laser cleaners are used for cleaning:

aircraft parts,

engines and other components to ensure they meet safety and performance standards.They are also used in aircraft maintenance and repair to remove corrosion and other types of surface damage. - Cars:

Laser cleaning machines are used to clean: automotive parts such as engines, brakes and gears, and to prepare surfaces for painting or coating. - Cultural heritage:

Laser cleaning machines are used to clean delicate and valuable artifacts, monuments and statues. They are used to remove dirt, contaminants and other types of surface damage without damaging the underlying material. - Electronic products:

Laser cleaning machines are used to clean delicate electronic components such as printed circuit boards without causing any damage. - Medical care:

Laser cleaners are used to clean medical equipment, implants and surgical instruments to ensure they are free of contaminants and safe for use. - Military:

Laser cleaning machines are used to clean military equipment such as weapons, vehicles, and aircraft. They are also used to remove explosive residues from surfaces.

In general, laser cleaning machines have a wide range of applications and are becoming a popular cleaning tool in more and more industries.

The difference between pulsed laser and continuous laser in cleaning

Pulse laser cleaning machines and continuous laser cleaning machines are two different types of laser cleaning equipment. There are three main differences between them:

- Laser output mode:

The pulse laser cleaning machine outputs the laser beam in the form of pulse to clean the dirt and coating on the surface.

The continuous laser cleaning machine cleans the surface by continuously outputting the laser beam. - Cleaning effect:

The pulsed laser cleaning machine has a short pulse width due to its high energy density. The dirt and coating on the surface can be peeled off in a very short time, so as to achieve a more thorough cleaning effect.

Continuous laser cleaning machines are suitable for some lighter cleaning tasks. Such as removing dust and stains from surfaces. - Scope of application:

Pulse laser cleaning machine is suitable for some fields that require high-precision and high-efficiency cleaning, such as:Electronic component,aerospace equipment,Automobile manufacturing, etc.

The continuous laser cleaning machine is suitable for the occasions that do not require high cleaning effect. Such as household cleaning and some simple industrial cleaning in daily life.

In short, pulsed laser cleaning machines and continuous laser cleaning machines have their own application occasions and advantages. The specific choice of cleaning equipment needs to be determined according to actual cleaning needs and conditions.

Laser rust removal VS traditional rust removal

Laser rust removal is a new type of rust removal technology. Compared with traditional rust removal technology, it has the following significant differences:

- Different principles:

Traditional rust removal is to remove rust and dirt by mechanical or chemical means. Laser rust removal is to directly irradiate the treated surface with a high-energy laser beam, so that the rust and dirt will expand, evaporate or peel off when heated. - Fast speed:

The laser descaling process is fast and can process large-area workpieces in a short time. Traditional rust removal requires manual or mechanical processing, which takes a long time. - High precision:

Laser descaling removes target surfaces with high precision. However, traditional rust removal is prone to scratches or affect the surface finish. - No need to use chemicals: laser derusting does not need to use any chemicals, which avoids the harm to the environment and human health.

- Wide applicability:

Laser derusting is suitable for surface derusting of various materials. However, traditional rust removal methods may have adverse effects when dealing with some special materials.

HANTENCNC machines are shipped with professional user manuals, and engineers can provide one-on-one online guidance. If you have any questions during use, you can contact us at any time, and we provide 24-hour online service.

Laser cleaning machine product introduction

Laser cleaning samples

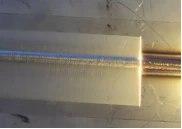

weld cleaning

cleaning oil stains

cleaning oxide

Features

HANTENCNC newly designed laser cleaning machine, non-contact cleaning, has the following characteristics:

- Degreasing

- Rust removal

- Decontamination

- Paint removal

Product description

- HANTENCNC independently developed by Hanteng CNC: the chassis is black and white, which is more high-end.

- The 4 handles on the back of the cabinet are made of thick aluminum alloy, which feels good.

- Lightweight and durable, easy to move.

- The handle is reinforced.

- No edges and corners design, more labor-saving, more convenient to carry.

- The rod-type pulse laser cleaning machine independently developed by Hanteng CNC adopts the design of thickened aluminum alloy rod. There are 4 universal wheels at the bottom of the case, and a portable handle. Make the laser cleaning operation of the mini portable pulse laser cleaning machine more convenient.

- Pulse laser cleaning head independently developed by HANTENCNC: 200W only 0.8g (excluding armored cable) 300W net weight is less than 1.6kg, which is more conducive to long-term hand-held operation.

Technical parameters

| Model | HTCM200 | HTCM300 |

|---|---|---|

| Laser Power | 200W | 300W |

| Pulse frequency range | 110-4000khz | 110-4000khz |

| Maximum pulse energy | 1.8mj | 1.8mj |

| Pulse Width | 10-500ns | 20-500ns |

| Delivery cable length | Factory 5 meters | Factory 5 meters |

| Laser wavelength | 1070nm | 1070nm |

| Welding head | Own brand | Own brand |

| Control System | Own brand | Own brand |

| Scan line diameter | 160mm/210mm/254mm/330mm/420mm(Optional) | 160mm/210mm/254mm/330mm/420mm(Optional) |

| Cooling system | Air cooling | Air cooling |

| Energy consumption | ≤1100 | ≤1100 |

| Anti-reflective protection | Have | Have |

| Power Requirements | 220V | 220V |

| Ambient temperature range | 10-40 Degrees | 10-40 Degrees |

| Package dimensions | 950*740*570mm | 950*740*570mm |

| Gross weight | 85kg | 87kg |

The laser cleaning system independently developed by HANTENCNC has the following characteristics:

Laser cleaning bottom control system and application software

- Built-in database system, which can save and edit 50 sets of process data;

- With online pulse width adjustment function (if supported by the laser),Optimize the process parameters according to the specific conditions on site;

- Optimized galvanometer control, sine wave signal control, effectively reducing the heat generation of the galvanometer and improving the service life of the galvanometer;

- The dual-axis version provides 7 cleaning modes: straight line, rectangle, circle, sine wave, double helix, free mode, and ring, to meet the needs of various application scenarios; the scanning speed is adjustable, up to 30m/s;

Cleaning method

Straight line method,Rectangle mode,Cycle mode,Sine mode,Double helix mode,Free Mode,ring.

Set the system language mode, currently supports

Chinese,English,Traditional Chinese,Russian,Japanese,Spanish,German,Korean,

FrenchAnd so on 9 kinds.

cleaning application

- Laser cleaning before and after aluminum alloy welding

- Metal surface oxide laser cleaning

- Laser cleaning oil and paint

- Laser rust removal

Which machine is more suitable for me?

The deciding factors for choosing a pulsed laser cleaning machine or a continuous laser cleaning machine depend on the type of object you are cleaning, the needs of your cleaning application, and your budget.

Pulsed laser cleaning machines are commonly used to remove dirt, paint or coatings from metal, glass and other hard material surfaces. Pulsed laser cleaning machines are better at removing dirt and coatings that are more difficult to clean, but are slower. Therefore, if you need to clean high-precision, small-batch objects, or need to perform delicate surface treatment and accurate cleaning, a pulsed laser cleaning machine may be more suitable for your needs.

Continuous laser cleaning machines are usually used to clean dirt, grease and dust from the surface of large objects. Compared to pulsed laser cleaners, it cleans faster, but may not clean as well. If you need to clean large quantities of objects, or need to complete cleaning tasks quickly, then a continuous laser cleaning machine may be more suitable for your needs.

Whether you choose a pulsed laser cleaning machine or a continuous laser cleaning machine, you need to consider the budget factor. Pulse laser cleaners are usually more expensive than continuous laser cleaners. If your budget is limited, you can consider some relatively low-priced models.

In the end, whether to choose a pulsed laser cleaner or a continuous laser cleaner depends on your specific cleaning needs and budget. You can also leave a message to us about your budget and needs, and we will recommend a suitable machine to you according to your requirements.