The fiber laser cutting machine is one of the more popular metal cutting models. It utilizes a fiber laser source to achieve perfect cutting results. Fiber laser cutter machines are becoming increasingly popular in the metal cutting industry.

But for some customers, metal fiber laser cutters are still relatively unfamiliar. Because people have yet to operate and use machines, rhetoric easily deceives them. So, what do customers need to know before buying a fiber laser cutting machine for themselves? In this article, we will give you some helpful advice.

Consider Your Own Needs

Before buying, we must evaluate our business scope, the thickness of the cutting material, which materials need to be cut, and other factors.

What Working Size Do You Need?

The standard size on the market is 1500*3000mm. In addition, there are smaller 1300*2500mm or larger 2000*3000mm. For some customers with an enormous business scope, the requirements for the scale of work are also higher. They wanted the machine to be as big as possible.

What Material Need To Be Cut?

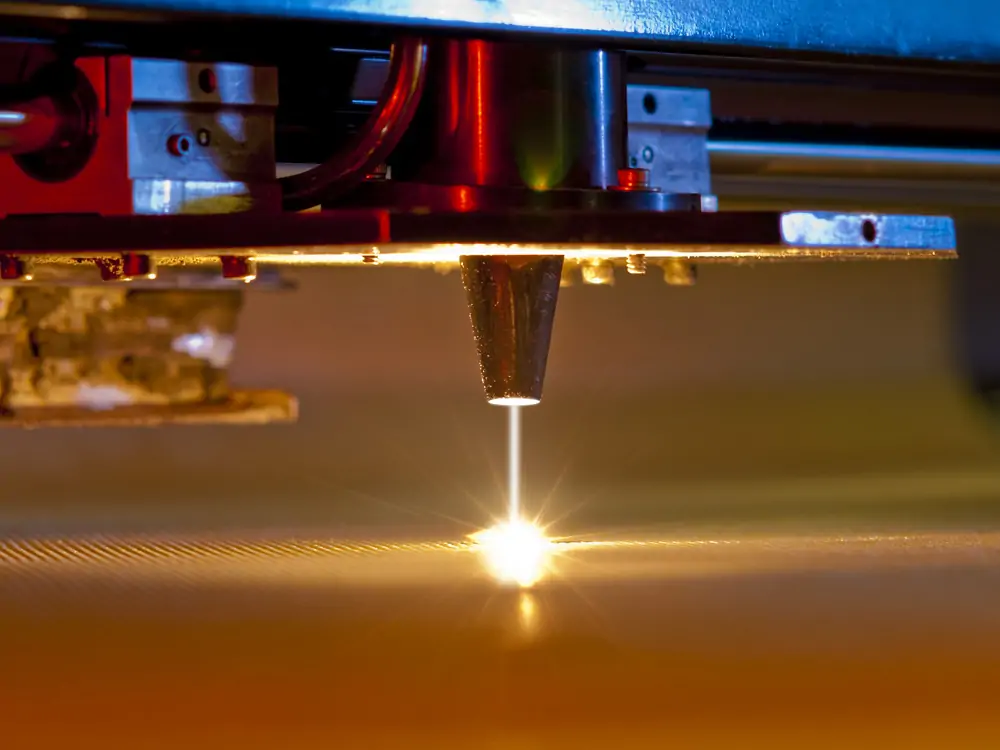

The metal fiber laser cutter can cut carbon steel, stainless steel, aluminum, gold, silver, and other metal materials. A fiber cutting laser machine uses light to cut metal. The light is focused on a single point, which can pierce and cut through metal. For different materials, there are different laser sources. We’ll go into more detail later in the machine factor section.

What is The Maximum Thickness of The Metal Being Cut?

As we all know, the laser power of fiber laser cutter is different, from low power, such as 500w and 1000w, to high energy, such as 10000w, 20000w, and 30000w. Foreign laser powers target different thicknesses. The higher the power, the thicker the material that can be cut.

Fiber Laser Cutting Machine Configuration

Fiber laser cutting machine is essential equipment in various industries. This cutting equipment ranges from tens to hundreds of thousands or even millions. To purchase a high-quality small fiber laser cutter, consider the following points.

Power

The power of fiber laser cutter machines is 1000w, 1500w, 2000w, 3000w, 6000w, etc. The higher the power, the more expensive it is. Generally speaking, for common metal materials, 3000w is enough. It would be best if you chose the appropriate power according to the material hardness of the product.

Speed

We chose the metal fiber laser cutter because it is fast enough. That is, we focus on processing efficiency. Start on the premise that the power can reach the standard. The sooner, the better. At the same time, it is necessary to consider the machine’s service life. One of the critical aspects is the configuration of machine operating parameters. Manual low speed and manual high speed affect the machine’s running speed in a manual state. Hardness comprehensively considers the overall performance of the laser cutting machine and the processed material. The machine should be set as large as possible to improve efficiency.

Precision

The cutting accuracy of fiber laser cutting machines is related to many factors, but most are mainly associated with the assembly technology of laser and laser cutting machines. For details, please consult the professional staff of the supplier.

Fiber Laser Cutter Machine Parts

When choosing a fiber laser cutting machine, pay special attention to the core components of the machine. These core components will directly affect the cutting accuracy and speed of the equipment.

Fiber-optic Laser

The fiber laser is the core part of the fiber laser cutter. Laser generation relies on fiber lasers. The life, cutting speed, and cutting quality of a piece of equipment largely depend on it.

Machine Tool

Machine tool structure is essential to cutting accuracy, stability, and durability. The size of the machine tool determines the workload of a one-time job. Once the size of the machine tool is determined, it cannot be changed. Be aware of the amount of cutting work to be done before choosing the size of the machine tool. You can choose a significant machine tool if you need mass production and the plate is enormous. Large-format machine tools can save loading and unloading time, improving production efficiency.

Servo Motor

The servo motor is the driving force for the fiber laser cutting equipment, affecting the cutting accuracy. The motor that controls the mechanical operation of the servo system is the motor indirect transmission device. An excellent servo motor can increase the working speed of fiber laser cutting equipment.

Cooling Device

The fiber laser cutter machine generates a lot of heat when it works. To ensure service life, a professional cooling device must be selected. The cooling device must have safety alarm prompt functions such as ultra-high temperature alarm, flow protection, and water level protection. Only in this way can we ensure that the fiber-cutting laser machine works at a constant temperature and prolongs the machine’s life.

Fiber Laser Cutting Machine Manufacturer

After determining the demand, you can first understand the market conditions. You can go to the supplier’s factory to see the performance and basic parameters of the machine. Choose a powerful manufacturer for early communication. In the later stage, on-site inspection of the qualification and strength of the manufacturer can be conducted. Learn more about equipment prices, post-training, payment methods, assembly processes, after-sales service, etc., in more detail.

In addition, the after-sales service of each manufacturer varies greatly, and the warranty length is also uneven. After-sales service depends on whether the manufacturer has a professional training system and ensures the manufacturer’s response to problems during use timeliness. No matter how good the quality of the equipment is, there may be problems in daily operation due to uncertain factors such as operation or maintenance. At this time, whether the manufacturer can respond in time and provide a solution is particularly important. It is also an essential factor when purchasing a fiber laser cutting machine. After all, timely response and resolution of faults are also a guarantee for improving efficiency.

Conclusion

These are critical factors to consider when purchasing a new fiber laser cutter. Choosing suitable fiber laser cutting equipment is a challenging task. Studying a machine’s characteristics and technical parameters can be difficult. Especially when there are countless options in the market, knowing the basic needs before buying will help you make an informed decision and choose the suitable fiber cutting laser machine.

Completing customer orders, maintaining a corporate reputation, and enhancing corporate competitiveness is also arduous for every supplier. Therefore, purchasing processing equipment with stable performance is the premise and basis. You try to choose a brand with a high market share and a sound after-sales service system. No matter if you buy any product, you need after-sales service. High-quality after-sales service reflects this common reputation and brand image. HantenCNC has nearly 20 years of experience in laser product manufacturing, providing laser equipment installation and services for dozens of users worldwide. Believe that HantenCNC will bring you different surprises.