In the long history of human industry, there have been many cleaning methods. Such as dry ice blasting and chemical cleaning. There are also traditional cleaning methods such as mechanical grinding and sandblasting. But with the improvement of people’s environmental protection and safety awareness. People are in urgent need of a cleaning method that is environmentally friendly, safe and does not damage materials. Thus, laser cleaning was born.

What is laser cleaning?

The principle of “laser” was first discovered by the famous physicist Einstein in 1916. It refers to “light emitted by stimulated atoms”. According to the wavelength of light, the laser is divided into fiber laser with a wavelength of 1064nm. 10640nm wavelength CO2 laser. There are also ultraviolet lasers with a wavelength of 355nm. Then all kinds of laser equipment widely entered into the life of human beings. Laser cleaning is one of the very common applications.

The principle of laser cleaning

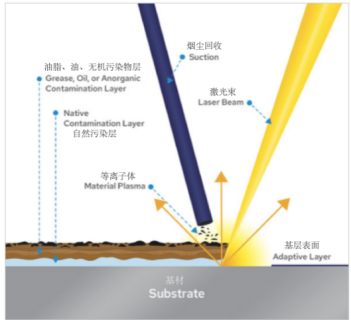

Its principle is the process of removing impurities by irradiating the surface of the cleaning material with a laser beam. Impurities on the surface of the material absorb the high-frequency energy of the laser and then heat up. It is then evaporated or sublimated. Finally, the surface of the material to be peeled off.

Advantages of laser cleaning

Compared with traditional cleaning methods. What are the advantages of laser cleaning produced by HANTENCNC?

- Laser cleaning belongs to non-contact processing. Compared with mechanical processing, it has the advantage of no cleaning dead angle. Its operation is simpler.

- Compared with dry ice cleaning, laser cleaning has no expensive consumables. It only needs to use electricity, so laser cleaning is less expensive to use.

- Compared with chemical cleaning methods, laser cleaning only produces physical reactions. No pollutants are produced. So it’s much cleaner.

- Compared with sandblasting cleaning, the smoke generated by laser cleaning is easier to recover. No pollution to the environment.

Although laser cleaning has many advantages, it is not a panacea (mainly due to the limitation of the current technological level). Before confirming the use of laser cleaning, it is best to carry out corresponding tests.

Classification of laser cleaning machines

Laser cleaning machines can be divided into the following four types according to the type of laser. They are: continuous laser cleaning machine, pulse laser cleaning machine, and compound laser cleaning machine.

Continuous laser cleaning machine

Continuous laser cleaning machine is the latest product launched by HANTENCNC in recent years. It uses a CW laser that is commonly used in cutting or welding machines. Commonly used laser power is 1000 watts, 1500 watts, 2000 watts, 3000 watts, etc. The advantage of this device is that the machine cost is low. High cleaning efficiency and simple operation. It is often used to clean some materials that do not require much cleaning surface. Such as truck paint removal, pipe rust removal, etc.

Disadvantages of continuous laser cleaning machines:

- Due to the use of continuous lasers, it is impossible to precisely control the residence time of the laser on the surface of the material. The laser burns continuously on the surface of the material, which easily deforms some metals.

- The continuous laser cleaning machine needs to replace the protective mirror every week. Improper operation may cause damage to the cleaning head or laser.

- The volume of the machine is large, and the laser and cleaning head need to be cooled by water, so it is not suitable for working outside.

- The power consumption is large, and the power of the whole machine is greater than 7 kilowatts, which is not suitable for home use.

Pulse laser cleaning machine

The second is the pulse laser cleaning machine. The earliest laser cleaners used pulsed lasers. Its common power is 100 watts, 200 watts, 300 watts, 500 watts, 1000 watts, etc.

Pulse laser cleaning machines are divided into single-mode lasers and multi-mode lasers according to the beam quality of the laser. So the pulse laser cleaning machine is also called Gaussian light and flat top light laser.

Single-mode lasers have a thinner core and better beam quality than multimode lasers. The energy distribution is strong in the middle and gradually decreases on the sides. Gaussian distribution, so called Gaussian light.

Multimode lasers have thicker cores than singlemode lasers, so the beam quality is poorer. The energy distribution is more even than single mode. The 3D plot of the energy distribution is steeper.

Gaussian beams have high energy density at the center and low energy density at the edges. Therefore, it is easy to cause the energy density of the center to be greater than the matrix damage threshold during cleaning. Easy to damage the substrate. The edge is below the cleaning threshold for contaminants, resulting in no contaminant removal at the edge.

Top-hat beams have the same energy density at the center and at the edges. Therefore, the problem of Gaussian beam generation can be better solved. There is little or no damage to the substrate during cleaning.

Single-mode laser cleaning machines are mainly used to clean rust on metal surfaces, or other oxides, as well as metal homogeneous materials. A common application is weld seam cleaning of metals. Weld cleaning can be done with a 100W 1.5mj.

Multimode lasers are often used to clean oil, paint, and other non-metallic pollutants on metal surfaces. The most classic application is tire abrasive cleaning. For example, the laser cleans off the rubber residue on the surface of the tire abrasive tool without causing damage to the tire mold. This application is typically done with a 500W 50mj laser.

Is there a machine that can remove rust, oil and paint without damaging the cleaning substrate?

According to the conclusion that single-mode lasers with the same power are stronger than multi-mode lasers. If the multimode laser reaches a certain power, it should be equipped with a lens with a smaller focal length. It is also an application that can simulate a single-mode laser cleaner. For example, for a 500W 50mj multi-mode laser, using the F160 focusing lens, the laser can at least reach the intensity of a single-mode laser of about 200W. However, the cost of a 500W 50mj laser is relatively high for some small businesses or individual buyers. So now you have a 200 watt 300 watt 5mj laser. Different cleaning effects can also be achieved with different focusing lenses.

So what are the differences in parameters between single-mode lasers and multi-mode lasers?

| single mode | multimode | |

|---|---|---|

| single pulse energy | 1.5mj ,2mj | 5mj,12.5mj,50mj |

| Laser power | 100W, 200W, 300W, 500W | 200W, 300W, 500W |

| cooling method | Up to 300 watts is air-cooled, 500 watts is water-cooled | 200W and 300W have air-cooled options, others are water-cooled |

By understanding the differences and parameters of the pulse laser cleaning machine shown by the above HANTENCNC engineers. Combined with their own requirements for laser cleaning. You can know what type of laser cleaning machine you need to use.

Compound laser cleaning machine

The third is the compound laser cleaning machine.

The composite laser cleaning machine is a cleaning method generated by the interaction of pulsed lasers and continuous lasers. It can effectively avoid the deficiency of a single cleaning method. It not only ensures the cleaning effect but also greatly improves the cleaning efficiency.

The composite laser cleaning machine is mainly used for cleaning thicker non-metallic coating materials. For example, anti-corrosion materials on the surface of aircraft or ships. However, the cleaning efficiency of traditional pulse laser cleaning machines is too low. The continuous laser cleaning machine will cause damage to the hull. So compound cleaning shines in this industry.

The above are the three main laser cleaning methods now. HANTENCNC has 18 years of experience in laser equipment production. The laser cleaning machines produced are sold to more than 30 countries in the world, and are widely praised by users. We not only produce laser equipment, we provide customers with more suitable and efficient cleaning solutions.