Connecting the battery cells is one of the most important steps in making batteries. This method has been used extensively in the EV, energy storage, and consumer electronics businesses. A battery pack is made up of many smaller cells. Before, people widely used contact welding to connect these cells. Unfortunately, this method does not provide uniform and high-quality welding. So, people have always tried to find a better solution, and finally, thanks to the battery laser welding technology,

Resistance welding is a widely used method for joining battery cells. However, this method does not always provide precision in welding. Unfortunately, it also makes the battery packs less durable and less efficient. Because of this, manufacturers are always looking for better ways to do this. And thanks to the Battery Pack Laser Welding Technique.

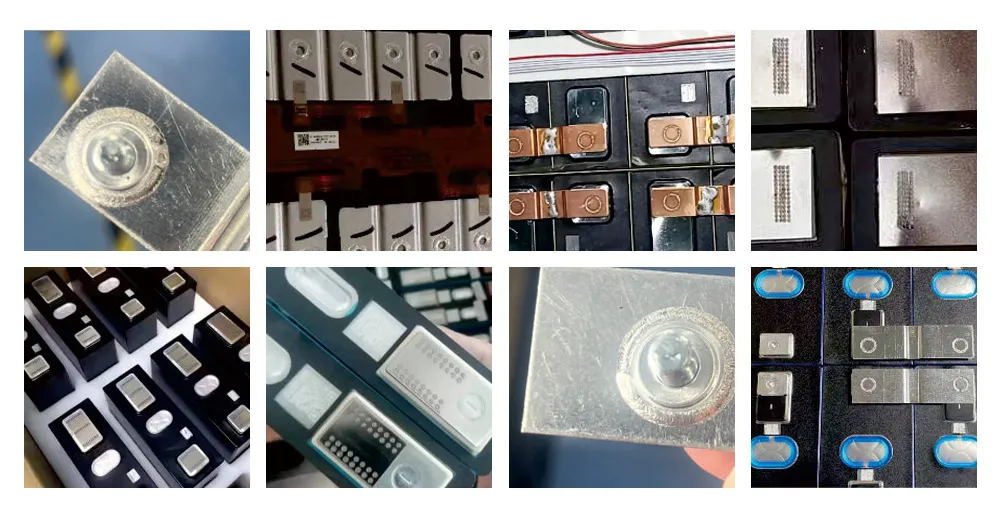

Battery laser welding machines are prevalent because they can make high-quality welds. This device offers better precision, control, and speed. As usual, it uses a highly focused laser beam to do the job. Also, your battery pack will experience less thermal impact.

This article is about battery laser welding. You will mainly learn the limitations of the resistance welding method. After evaluating the limitations, you can find battery laser welding opportunities in the market.

What is a Battery Pack?

Have you opened a battery pack before? If you did, you might know how the battery cells are connected. This connection is mainly done through the welding process.

So, what does a battery pack contain? The major parts of the device are battery cells, connection points, an electronic control board, also known as BMS and a casing. They are all responsible for storing and discharging electric energy in their circuits. In this case, the BMS or battery management system monitors and controls the whole operation.

A battery pack may include other parts besides the above four components. Some high-quality batteries offer enhanced safety features, like thermal management. You may also find a voltage regulator.

Challenges in Contact Welding of Battery Cells

Now comes the question of which welding method is the best: laser or traditional resistant welding? To answer this, we must be familiar with the challenges of the conventional method. Then, we can determine the scope of battery laser welding.

(1) During contact generation, high amounts of heat are generated. It may damage sensitive battery cells. Also, overheating may affect the battery’s performance or even cause failures.

(2) Contact welding is not always the same. If not carefully done, the process can create weak or uneven joints.

(3) Contact welding sometimes struggles with precision. This often happens when you work with small or thin materials. As you know, battery cells are connected using thin metal connectors.

These challenges generally make contact welding less suitable for modern pack manufacturing. They also open the scope of battery laser welding.

Why Use Battery Laser Welding for Battery Pack Manufacturing?

Battery laser welding is continuously growing in modern manufacturing. The highly focused laser beam makes the job possible, whereas the contact method is nearly impossible. This modern welding technique offers several benefits. Some of the crucial benefits are:

Precision and Control

Laser welding is known for its precision. The laser beam is very focused, so it only hits the spot where you want to weld. Laser welding in batteries lowers the chance of mistakes and keeps cells from getting damaged.

Consistent Result

The best thing about battery laser welding is that the products are always identical. Each weld is done with the same amount of accuracy, which makes it possible to create high-quality battery packs. Contact welding, in this case, often produces inconsistent weld.

Also, you must have a professional hand to ensure a good weld with contact welding. Battery laser welding makes you confident, and you don’t necessarily have to be an expert.

Fast Production Speed

Battery laser welding is much faster than the contact welding method. Laser welding is an automatic process. You can complete hundreds of welding tasks in an hour. If it is a fly laser welding machine, you may expect more. Faster production means less cost per product. So, battery laser welding also reduces the production cost.

High-quality Welding

When working with laser welding, defects are less likely to occur. The battery cells and connection are strongly connected since the laser beam melts the metal quickly and evenly.

Minimal Thermal Impact

When you weld, heat is a big problem. Battery cells can have sensitive parts that get damaged by too much heat. Laser welding lowers this risk by focusing the heat on a small area while leaving the rest untouched.

Durable Laser Welding Battery Cell

The laser welding battery cell ensures that everything is linked correctly and can work well for a long time. It lasts longer than the contact welding battery cell.

How Does Battery Laser Welding for Battery Pack Work?

The battery laser welding process is typically similar to other laser welding methods. Both automatic and handheld laser welding are used in battery pack manufacturing.

Before welding, the battery cells are cleaned and positioned correctly. Note that contaminants may interfere with the quality of the laser weld. Next, you aim the laser beam at the spot where you want the cell and connector to join.

When the laser hits the surface, the target area melts. After cooling, the substance hardens and strongly connects the connector and the battery cells. The weld cools quickly due to the laser’s high precision, so the surrounding area doesn’t feel the heat as much.

Three components play a crucial role in laser welding. First, the laser source produces the laser beam. There are both continuous and pulse-type lasers. A pulsed laser beam is widely used for battery laser welding. Second, the optics of focusing mainly amplify and focus the laser beam on the exact spot. Finally, the cooling system manages the heat required for the process.

Tips on Battery Laser Welding for Battery Pack

As you know, a battery pack consists of several battery cells. Accurate laser welding ensures your battery performs well and does not produce excess heat. If you don’t weld properly, the links can weaken, the battery can die, or it can get too hot. For this reason, it is very important to follow the right steps to get the best result.

Tip #1. Select a Proper Way to Clamp

A clamp typically holds the battery cells firmly in place during welding. Thus, choosing the right clamping method is very important. This will ensure no misalignment or weak welds. When this happens, ensure the clamps never put too much pressure on the cells, which could damage them.

Tip #2. Make Sure Cells Are Placed Correctly

Before you weld, you should also ensure the battery cells are lined up correctly. Incorrect alignment is the main reason for bad welds. Eventually, your battery pack may not work as expected, so putting the battery cells in the right place is very important.

Tip #3. Optimize Bush Bar Design

Bush bars are also connectors in battery packs. They are mainly responsible for conducting and distributing current. Overall, busbars ensure reliable power flow. Therefore, optimizing bush bar design before welding is very important.

Copper is an ideal choice for this application. This material is prevalent for many reasons. First, it is lightweight, and second, it has high electric conductivity. However, the bush bar must be thick enough to handle the current.

Tip #4. Making Plans for How to Handle Batteries

Batteries are sensitive and can be easily harmed if not handled correctly. So you can devise a plan for handling the whole packing process. You could initiate a few techniques to do the work more professionally in this case. Safe lifting techniques or professional storage are typical steps you can take during welding. However, if you run a business, ensure everyone is well-trained.

Tip #5. Ensure Proper Quality Assurance in Battery Laser Welding

Finally, QA, or quality assurance, is another key work in battery laser welding. You can ensure quality in several ways. One of the best ways is to do a regulatory inspection. Use appropriate testing methods to evaluate the quality of each weld.

The Best Battery Laser Welding Machine

The Hanten HTW1500 is one of the best laser welding machines for battery backs. This machine is equipped with an articulated galvanometer system. Articulated means moving the laser gun at the X and Y axes. This way, you can control the laser welding at your convenience. Thus, it offers more precision than regular laser welders. Because of this feature, HTW1500 becomes an ideal choice for battery laser welding.

Moreover, the HTW1500 is equipped with a powerful fiber laser source. It can mostly be used with a 220V power supply. However, this device gives you a working area of 900* 400* 1380 mm and weighs only 40 kg.

The HTW1500 is also perfect for small—and large-scale battery welding jobs. It is easy to use and has an easy-to-understand control method. Overall, it’s a flexible option that can be used to make any battery pack.

Final Thought

Battery pack laser welding is continuously in high demand in modern back manufacturing. It is more efficient, creates higher-quality welds, and offers cost-effective solutions. Because of this, battery pack factories can guarantee a higher battery efficiency rate.

Efficiency isn’t just a matter of technology but expertise. You must be careful during laser welding and know how to do it correctly. This article has mentioned five tips on correctly doing battery last welding and the best laser welding machine for batteries.

Contact us if you have any questions or want to know more about our laser machines. Our team of experts is always happy to assist.