Traditional marking methods are time-consuming and require labor. However, laser marking saves time, money, and labor. There are a few laser marking machines in the market, and the MOPA laser marking machine is one of the most popular devices.

Today, we will mainly discuss the basics of the MOPA laser and how we can use it to mark things. You can pick the right tool for your job if you understand these basics. We will also explain how MOPA lasers are different from other kinds. Finally, we will highlight some project ideas you can come up with for a MOPA laser marking machine.

What is a MOPA Laser?

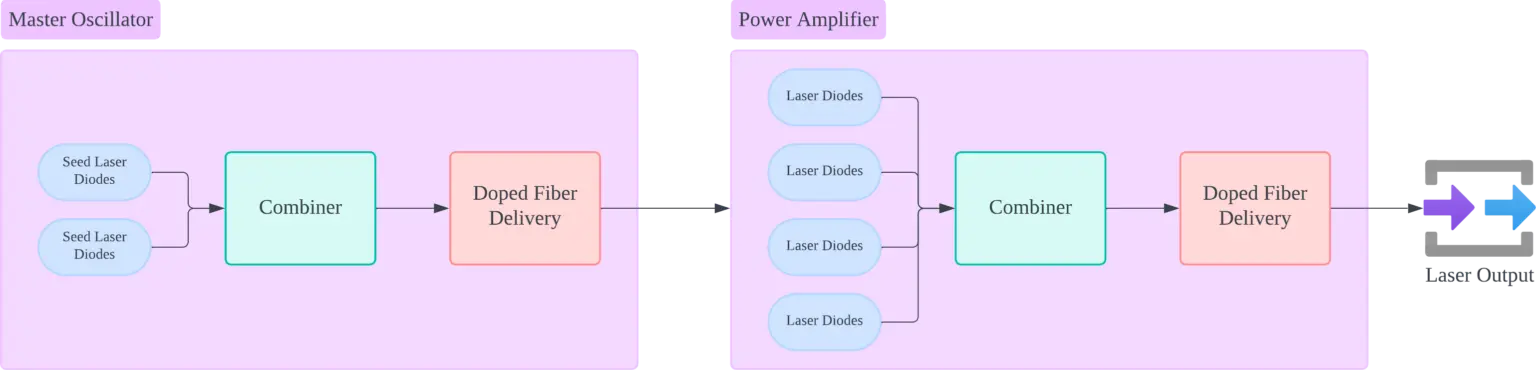

MOPA stands for Master Oscillator Power Amplifier. It is a specialized type of laser system.

The process in MOPA lasers starts with the master oscillator, which makes the first laser pulse. A power amplifier then boosts this pulse, giving complete control over the pulse’s properties. This configuration ultimately leads to a highly flexible MOPA laser.

MOPA lasers provide excellent flexibility. You can adjust the pulse characteristics based on your needs. In addition, this laser can be used for a variety of projects.

MOPA lasers’ adaptability is particularly helpful in laser marking and engraving. In these applications, precision is the key. Unlike CO2 or fiber lasers, MOPA lasers offer superior results. You can even create colors on markings.

However, you can fine-tune parameters with precision. Overall, you can improve the quality of the markings.

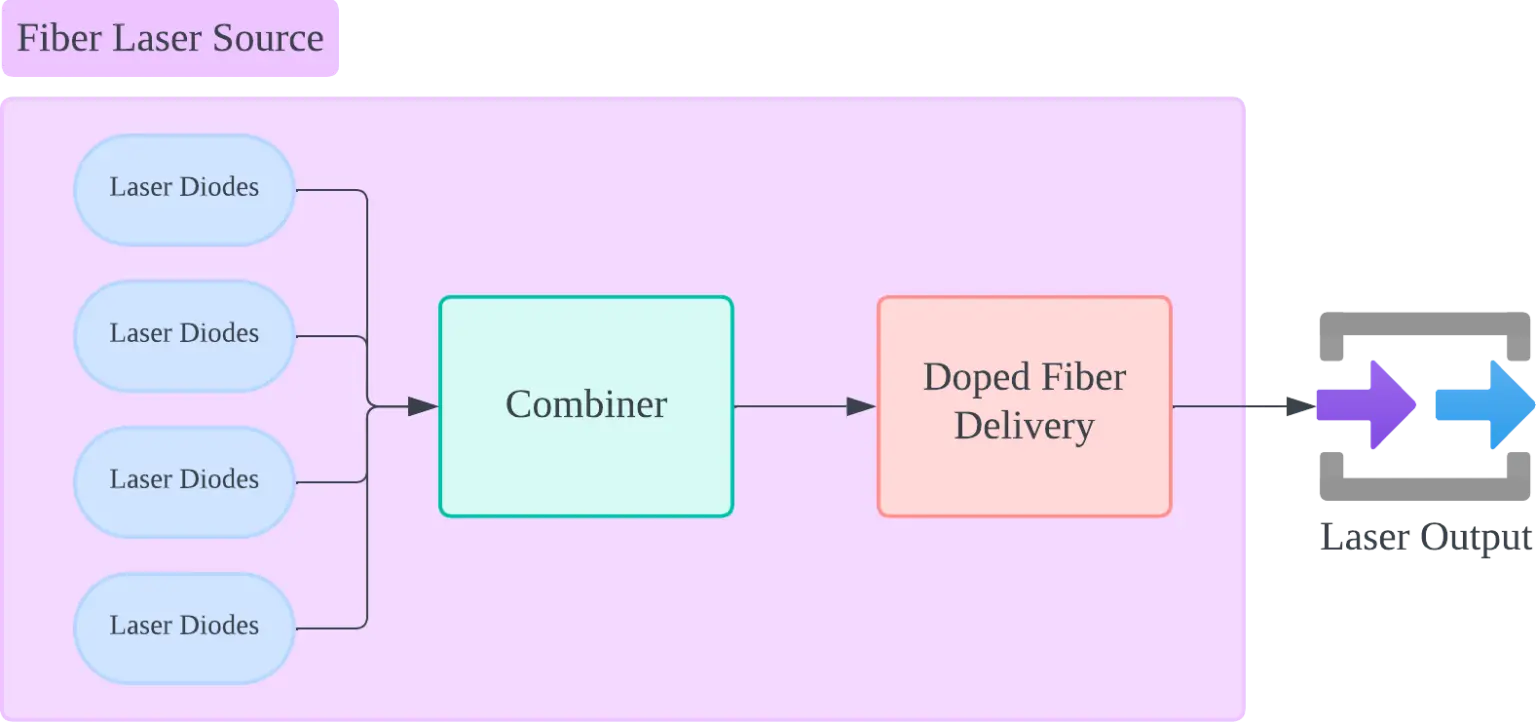

MOPA laser is a specialized type of fiber laser. Both employ optical fibers for amplification. If you look closely at the schematic diagram of the MOPA laser, you will find two main portions. Both portions have a fiber delivery system to amplify the pulses. Because of this, MOPA lasers are called a particular type of fiber lasers.

MOPA Laser VS Fiber Laser

Fiber lasers use optical fibers to amplify light for cutting or welding. They excite rare earth ions within the fiber to emit laser light. The laser beam then travels through the fiber and gains energy as it bounces back and forth. After being boosted, the light emerges from the fiber through a mirror as an intense laser beam. They are excellent for cutting and welding.

On the other hand, MOPA lasers allow for precise control over pulse parameters. As a result, they are great for marking and engraving applications. Let’s check out the following table to learn more about their differences.

| Feature | MOPA Laser | Fiber Laser |

| Operation Principle | Uses a master oscillator and power amplifier | Utilizes optical fibers as the gain medium |

| Pulse Control | Offers greater control over pulse parameters | Generally, it provides fixed pulse parameters. |

| Pulse Duration Range | Offers a broader range of pulse durations | Limited range of pulse durations |

| Peak Power | Typically offer higher peak power | Peak power may vary based on specific configuration |

| Pulse Energy Stability | Generally, it provides better pulse energy stability | May exhibit variations in pulse energy |

| Beam Quality | Typically offers higher beam quality | Beam quality may vary depending on specific factors |

| Applications | Suitable for precision marking and engraving | Widely used in cutting and welding |

| Cost | More expensive than fiber lasers | More cost-effective than MOPA laser |

What is the MOPA Laser Marking Machine?

A MOPA laser marking machine is a laser device used to create marks on various materials. It consists of a laser source, marking head, and control system.

The laser source generates a high-energy laser pulse. The marking head directs this laser beam on the material’s surface. And finally, the control system allows you to control the operation.

It’s easy to use a MOPA laser marking machine. Laser marking software lets you customize your design. Lightburn or laserGRBL are two common choices in this case. You have to get the plan ready and correctly set the laser. Then, boom! Your MOPA laser marking machine will make the mark instantly.

MOPA laser marking machines are often used in medical, electronics, manufacturing, and the car industry. People mostly use it to identify, name, and serialize products.

MOPA laser marking machines are better than other laser marking machines in many ways. Because of these benefits, MOPA laser engravers are famous in many fields.

- You can precisely control the length, frequency, and power of MOPA laser markers.

- They can create high-quality markings on various materials.

- Indeed, MOPA lasers are high-speed. It ensures increased productivity.

- MOPA laser engravers offer color marking on metals. It is one of the attractive features of this laser device.

What Can You Do with A MOPA Laser Marking Machine?

A MOPA laser marking machine can do many things. Its features open a world of possibilities for various projects. Let’s delve into some practical tasks you can accomplish with it.

Product Identification

Using a MOPA laser marking machine, you can engrave text on various products. This can include the name and description of the product or safety guidelines. You can also engrave barcodes or serial numbers, which helps keep track of goods.

Branding and Logo Marking

You can make nice-looking branding items with a MOPA laser marking machine. You can mark on any items, such as consumer goods or promotional items.

Laser marking generally improves your brand visibility. People can quickly identify your company and product.

Personalizing Items

With a MOPA laser marking machine, you can customize your items. You can engrave your name, initials, or messages on various materials.

Customized items are popular for gifting. It is also very famous for promotional campaigns.

Signage

You can create various signage boards with text, logos, and designs. One interesting fact about the MOPA laser is that it works on multiple materials. You can use metals, acrylic, wood, or even plastics.

Signage plays a crucial role in branding, advertising, and wayfinding.

Various Laser Marking Business Ideas

It’s easy to start a business with the MOPA laser marking device. Imagine things happening, and it helps you make them happen. The table below shows some more business ideas you might want to consider.

| Business Idea | Description |

| Laser Etch QR Codes | Wi-Fi access, food menus, payment options, and table booking |

| Custom Jewelry Engraving | Rings, bracelets, and necklace |

| Firearms Engraving | Personalized designs or compliance markings for gun owners |

| Glass Etched Products | Wine glasses or bottles with laser-etched logos, patterns, or messages |

| Promotional Product Branding | Pens, keychains, or drinkware |

Laser Color Marking: Create More Than Just Marking

As the name suggests, laser color marking uses lasers to leave colored marks on objects. It works by adding a specific layer to the surface of the object. In color laser marking, when the laser hits the object, a colored layer is added to it.

MOPA laser marking machines are unique because they have exact control over the laser pulses. Because of this, you can make different colors on the material’s surface. By changing these points, MOPA lasers can create a range of shades and colors. However, you can color marks on various materials, such as metals and plastics.

Laser color marking is used in artwork, brand names, and unique products. It improves the aesthetic appeal across diverse industries.

How Do You Use A MOPA Laser Marking Machine?

Using a MOPA laser marking machine is simple. All you need to understand is how it works, which involves several steps.

Step 1 Safety Precaution

Before starting, wear appropriate PPE, like safety glasses. Ensure the machine’s safety features are enabled. This step is generally necessary to prevent accidents.

Step 2 Preparation & Design

Clear obstructions and power the machine to prepare the work area. Securely place the material you want to engrave on the platform. Use user-friendly software to customize your design. In this case, you can consider Lightburn or laserGRBL. These two software programs are well-known worldwide.

Step 3 Machine Calibration

Once you customize your image, use the software to change the laser parameters. And then calibrate the machine. In this case, you can adjust the height of the laser gun. Start the red-light test and ensure the image is lined up correctly on the material’s surface. Most of the time, machine calibration is needed to get the marks you want.

Step 4 Marking Process

Initiate the marking process through the software interface. The MOPA laser will precisely etch or engrave the design onto the material. Monitor the process to ensure accuracy and quality.

Step 5 Post-marking Treatment

After marking is complete, inspect the quality of the mark. Do the post-marking treatment based on different materials. For example, if you work with wood, you need cleaning after laser marking. Sometimes, you may also need to apply protective coatings to improve durability.

Expert Advice

MOPA laser marking machines are a particular type of fiber laser machine. They offer precise control over laser pulses and provide better marking results than fiber lasers. Because of this, MOPA laser engravers are widely famous in many applications.

However, you must consider a few points when choosing MOPA laser marking tools. This information can help you select a suitable device for your job.

- Determine the required laser power. Some popular choices are “20w MOPA fiber laser“, “50w MOPA fiber laser“, “60w MOPA fiber laser“, and “100w MOPA fiber laser“.

- Ensure the machine is compatible with the material you want to mark.

- MOPA laser marking machines offer excellent pulse control. All you need to know is the right spec for your project.

- The chosen device must be compatible with the software. Otherwise, you may not get the desired result.

- Ensure the working area is sufficient for your job.

- Check the manufacturer’s customer support.

- Finally, consider the budget.

Contact us today to learn more about our MOPA laser marking machines. Reach out to us for personalized solutions.