Both laser welding and brazing are ways to join different kinds of metals together. They do have many similarities—that’s true! However, their uses have some critical differences; most people get this wrong. Consequently, a big problem arises when picking the correct method. Therefore, the topic “Laser welding vs brazing: What’s the Difference” is crucial to discuss.

Understanding between these two methods is not tricky. You must understand how a welding process works. You can quickly understand their differences if you are already familiar with them. The main difference between these two methods is the use of filler material.

Laser welding works by melting the base materials and joining two separate metals. In this case, the base metals must be similar. Otherwise, the weld strength won’t be enough because of incompatibility. On the other hand, laser brazing only melts the filler to join two separate materials. You can also use dissimilar materials in this case.

This is the main difference between these two fabrication methods. This article will briefly discuss these fundamental differences. We hope this information can help you choose the correct method for your project. Let’s get started!

What is Laser Welding?

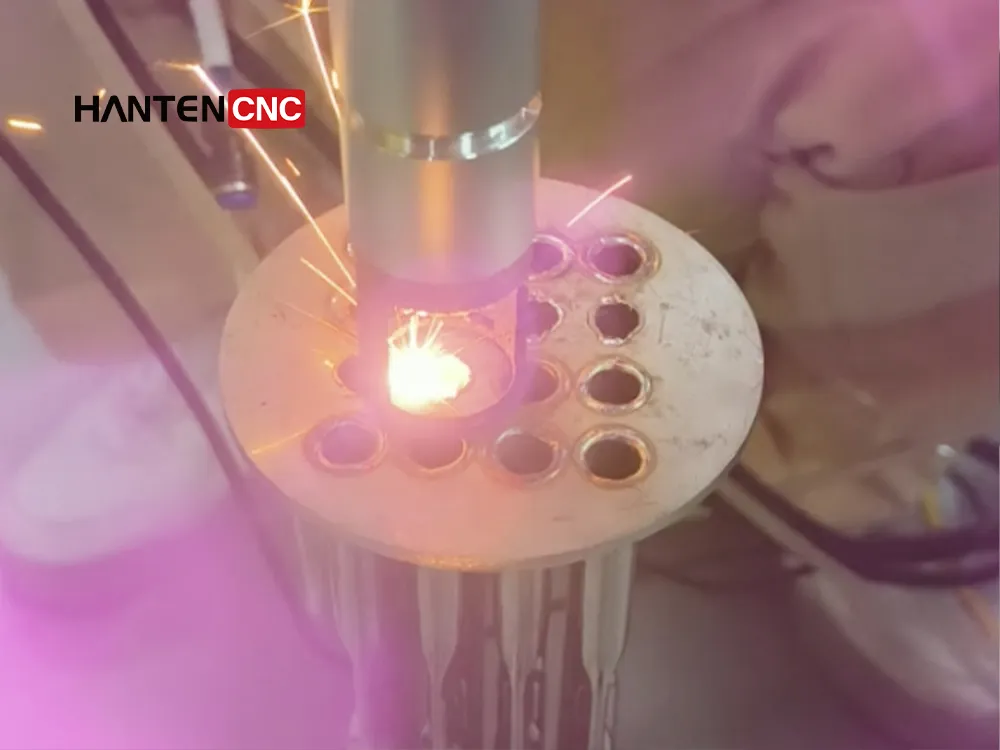

Laser welding is the process of joining metals by melting the mating surfaces. This machine uses a highly focused laser beam to melt the mating surfaces. The molten metal fuses and forms a robust joint when it cools. Since no filler material is used, the joint becomes very strong and durable.

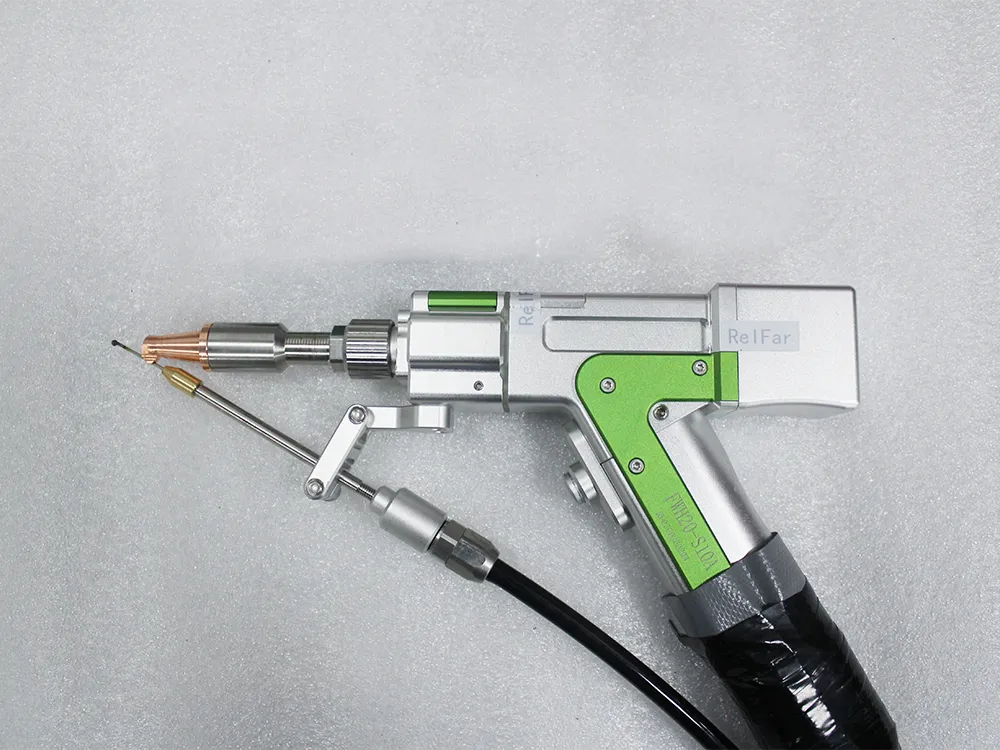

There are various laser beams, but fiber lasers are suitable for laser welding tasks. The laser beam from the laser source reaches the laser gun through optical fibers. Then, with the help of mirrors, these laser beams are focused on a point. This point generally concentrates the heat, which is later used to melt different metals.

The laser concentration level may change depending on the base metals. Therefore, it is critical to maintain the appropriate laser settings. Some metals have a very high melting point, while some have high heat conductivity. Follow the manufacturer’s guide to learn more about the settings.

Advantages of Laser Welding Compared to Laser Brazing

(1) Laser welding can offer you stronger bonds. As you know, this method produces a metallurgical bond between the base metals. Since there is no filler, the joint it produces gains strength, just as the base metal does.

(2) Laser welding is generally faster than laser brazing. The filler materials need not be prepared; it is a plug-and-play process.

(3) The best thing about laser welding is that it creates a less heat-affected zone or HAZ. As a result, you can ensure less distortion and better control of your metal part.

(4) Laser welding offers very high precision. This method makes delicate components such as jewelry, electronics, and medical items.

(5) Finally, the most crucial factor that heavily differentiates laser welding and brazing is the use of filler. Laser welding is generally an autogenous method. Therefore, it doesn’t need any extra filler material to join metals.

Limitations of laser welding

(1) Laser welding machines are generally more expensive than laser brazing machines. However, many laser welding machines come with brazing features. This means you can perform both welding and brazing using the same device.

(2) When you do laser welding, you must ensure the gap between metal parts is as minimal as you can. Laser welding typically requires the parts to be closely aligned. Otherwise, there won’t be enough material to fill the gap. Because of this, you may end up with unfinished welding.

(3) Laser welding is typically not suitable for thin metals. Since the heat is applied directly to the metal, distortion is possible when using thin metal sheets.

(4) Laser welding technically requires a higher heat input near the melting point of the base metal. Because of this, this method sometimes causes thermal stress or warping.

(5) Laser welding can create a spatter, which may require post-processing or extra finishing on the final part.

What is Laser Brazing?

Laser brazing is also a common material joining method. However, in this method, the base materials are not heated. Instead, a filler material is used and melted to join different parts.

A laser brazing machine usually uses a highly focused laser beam to create concentrated or localized heat on the filler. The filler melts and fills the gap between the materials. When it cools, it forms a strong bond.

Advantages of laser Brazing

(1) Laser brazing typically requires less heat input. It uses lower temperatures than laser welding, which reduces the possibility of warping and thermal damage.

(2) Since you use filler to join two separate materials, you can attach almost anything. For example, the copper-based filler is compatible with joining steel, copper, and nickel.

(3) The filler material in laser brazing can fill small gaps. As a result, you can work with complex shapes. Since the base metals do not melt, there is minimal distortion. Because of this, you can technically work with thin sheets or components.

(4) laser brazing generally produces clean and smooth joints. Therefore, you won’t need to worry about post-processing or extra finishing work.

(5) Laser brazing machines are generally cheaper than laser welding machines. This could be a better choice if you are looking for a cost-effective solution.

Limitations of Laser Brazing

(1) The main problem with laser brazing is the bond strength. This method can not offer you with stronger bonds. Because of this, this method is not suitable for high-stress applications.

(2) This method entirely depends on the filler material. Therefore, you may need to count more operational costs.

(3) Since laser brazing can not offer as strong a bond as laser welding, this method is not ideal for thick metal parts.

(4) Laser brazing is limited to certain materials. You can work with all materials. Some metals do not bond well with common brazing fillers.

(5) Laser brazing is generally slower than laser welding. Although this process could be automated, manual brazing takes longer than welding. Note that the need for precise filler material use can slow down production.

Laser Welding vs Brazing: What’s the Difference?

You have gone through the pros and cons of each type of laser bonding method. Let’s summarize what you learned from the previous two sections. The following table summarizes the main content of “laser welding vs brazing.”

| Feature | Laser Welding | Laser Brazing |

| Process | Fusion-based, melts the base metal | Adhesive-based, only melts the filler metal |

| Heat Input | High and localized heat | Low and more widespread heat |

| Bond strength | A higher and more powerful bond | Moderate and depends on the filler |

| Materials | Mostly metals, including steel, aluminum, and titanium | Wide range of metals, ceramics, and dissimilar materials |

| Joint type | It needs tight fit-up and minimal gap | It can bridge gaps and is highly suitable for dissimilar materials |

| Finishing | It needs post-processing for a smooth finish | Typically produces a smooth and finished surface |

| Application | High-precision welding, automotive, and medical devices | Plumbing, electronics, HVAC, and some aerospace equipment |

| Cost | Higher equipment cost and lower operation cost | Lower equipment cost but higher material cost |

Laser Welding vs Brazing: What are the Opportunities?

You have already learned in detail about these two methods (laser welding vs brazing). You have also learned about their differences. Now, let’s learn about their uses and vast possibilities.

First, let’s start with laser welding. As you know, this method melts the mating surfaces of the base metals and joins them. This makes the joint very strong and durable. This facility is used in various industries, such as battery manufacturing factories.

Lithium battery tabs and components are attached in battery factories using laser welding machines. In this case, you do not need any filler.

Also, you will see the wide use of laser welding in jewelry factories. Tiny jewelry parts that are very difficult to attach to the naked eye are challenging. Laser welding machines can do it very quickly.

In addition, laser welding can also be used in the automotive, aircraft, electronics, and medical industries. Products such as car body panels, exhaust systems, fuel tanks, surgical tools, and PCB components are popular in these industries.

Laser brazing, conversely, shines in the automotive, HVAC, electronics, and other industries. People use laser brazing in the car industry to create car roofs, doors, and body panels. You can use this method in the HVAC system to join copper and aluminum heat exchangers. Besides, joining electrical connections, terminals, and small metal components is noteworthy in the electronics industry.

Expert Advice

Hopefully, you have already understood the difference between laser welding and brazing. You may already understand which method you should choose. Let’s take a look at it again.

When you are choosing between these two methods, there are some things that you must consider.

(1) First, see what kind of metal you will be working with or doing. If you need to join dissimilar metals, then definitely choose the laser brazing method. If you are looking at similar metals, then laser welding is the best method.

(2) The second thing that comes to mind is the strength of the joint. Where will you use this joint? Is there frequent stress in the place where you will use it? You should choose the laser welding method if there is such a situation.

(3) Consider heat sensitivity. Laser brazing is the best option for heat-sensitive materials to avoid warping.

(4) Consider gap size. If your parts have gaps, laser brazing can fill them. However, if you want to use laser welding, you must ensure a tight fit.

(5) Consider your project budget. Laser brazing machines are generally cheaper but have higher operation costs. On the other hand, laser welding machines are usually expensive but have lower operation costs.

If you have any questions, feel free to reach out to the HantenCNC customer support team.