With the development of industrial surface cleaning, composite laser cleaning is becoming a powerful and efficient technology. By integrating the strengths of continuous lasers (or semiconductor lasers) with those of pulsed lasers, composite laser cleaning is an advanced method for cleaning.

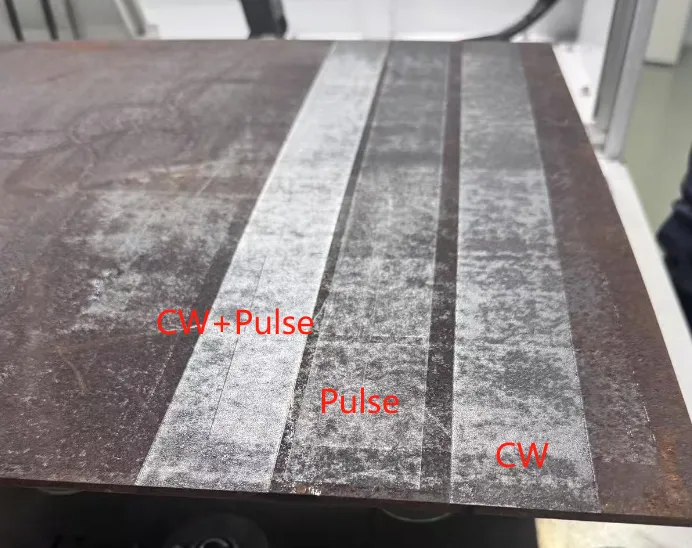

In this article, we will compare the laser cleaning efficiency and quality of the three cleaning methods—composite, continuous, and pulse laser cleaning— by removing rust with an average thickness of 500-600μm.

Composite laser cleaning utilizes the unique cleaning advantages of both continuous laser and pulse laser, acting simultaneously on the product surface to significantly improve cleaning efficiency.

In the meantime, the efficiency of composite laser cleaning is much greater than that of a pulse laser cleaning, and the cleaning quality is higher than that of a continuous laser cleaning.

Generally speaking, the combination of a semiconductor laser and a pulsed laser is suitable for removing paint layers. While the combination of a continuous laser and a pulse laser is ideal for cleaning rust.

1. Test Setup and Equipment Overview

We conducted a standardized test to compare the cleaning performance of composite, pulse, and continuous laser methods using rusted carbon steel samples and controlled equipment settings. Below is an overview of the lasers, cleaning systems, and materials used in the experiment.

1.1 Continuous Laser Cleaning Machine Settings

For continuous laser cleaning, we used a 2000W JPT fiber laser with a core diameter of 50 μm and a central wavelength range of 1070–1080 nm. The laser operated in continuous wave (CW) and was water-cooled to maintain performance during extended operation.

Laser Brand: JPT

Core Diameter: 50 μm

Laser Power: 2000 W

Central Wavelength: 1070–1080 nm

Operating Mode: Continuous Wave (CW)

Cooling Method: Water-cooled

1.2 Pulse Laser Cleaning Machine Settings

The pulsed laser cleaning setup featured a 300 W JPT pulsed laser with a maximum pulse energy of 5 mJ. This system was air-cooled and optimized for high-precision surface treatment.

Laser Brand: JPT

Laser Power: 300 W

Maximum Pulse Energy: 5 mJ

Cooling Method: Air-cooled

1.3 Composite Laser Cleaning Machine Settings

For composite laser cleaning, we used a dual-laser configuration integrating one QCS port and one QBH port in a water-cooled cleaning gun, with a focal length of 210 mm.

This setup allowed the simultaneous application of both pulsed and continuous lasers to the same surface area.

Composite Laser Cleaning Gun:

One QCS port and one QBH port

Water-cooled

Focal length: F = 210 mm

1.4 Rusted Test Material

The rusted test material was carbon steel Q235, featuring a uniform rust layer with an average thickness of 500–600 μm. Cleaning results were evaluated through visual inspection and electron microscope observation at 200× magnification, providing both macroscopic and microscopic assessments of surface quality.

Test Material

Rust thickness: approximately 500–600 μm

Material: Carbon steel Q235

1.5. Cleaning Workstation:

All cleaning processes were carried out on a gantry-type three-axis servo motor platform, controlled by a PLC system. The cleaning speed was stabilized at 30 mm/s to ensure consistent movement across the test samples.

1.6.Evaluated Cleaning Results Method

Cleaning results were evaluated through visual inspection and electron microscope observation at 200× magnification, providing both macroscopic and microscopic assessments of surface quality.

(1) Visual inspection

(2) 200× magnification using an electron microscope

2. Rust Removal Test Using Continuous Laser Cleaning

First, let’s test the effect of continuous light cleaning at an output power of 2000 watts, a frequency of 3000kHz, and a speed of 30mm/s to remove rust.

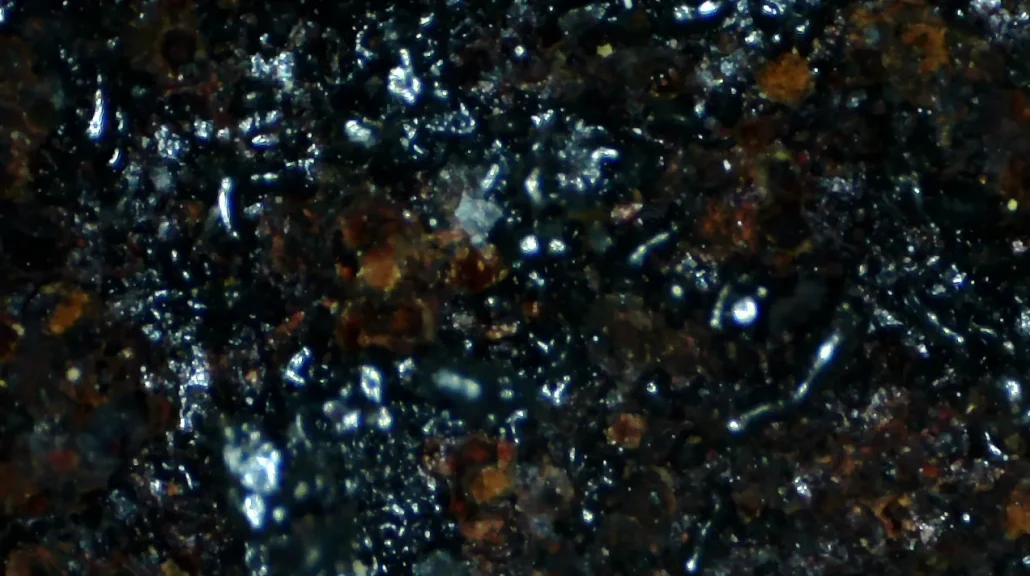

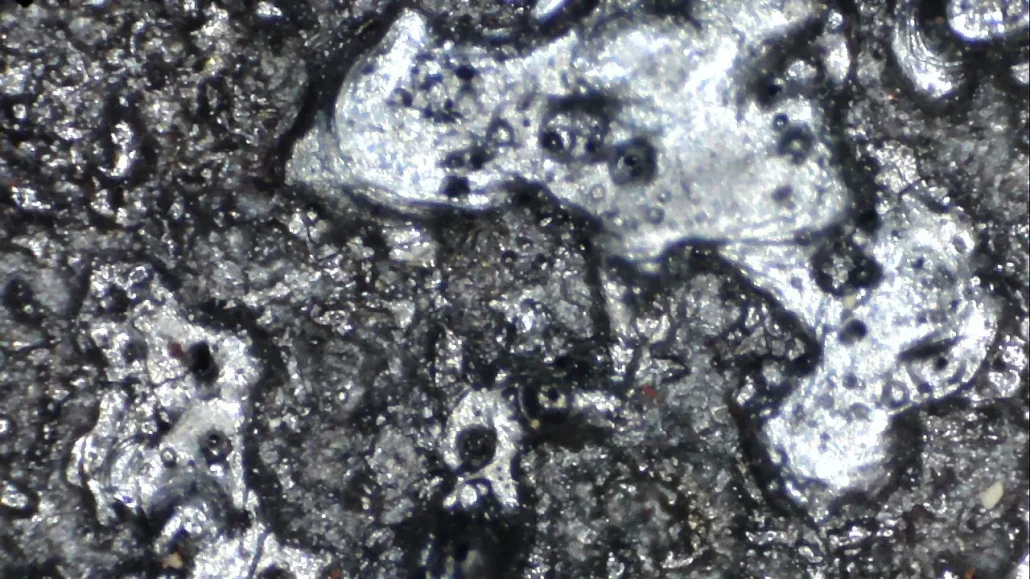

In the original state of the iron plate, we randomly selected two points, and the imaging under the electron microscope is as follows:

It can be seen that the first and second images are very different, indicating that the rust state of the iron plate surface is complex and the thickness of the rust varies.

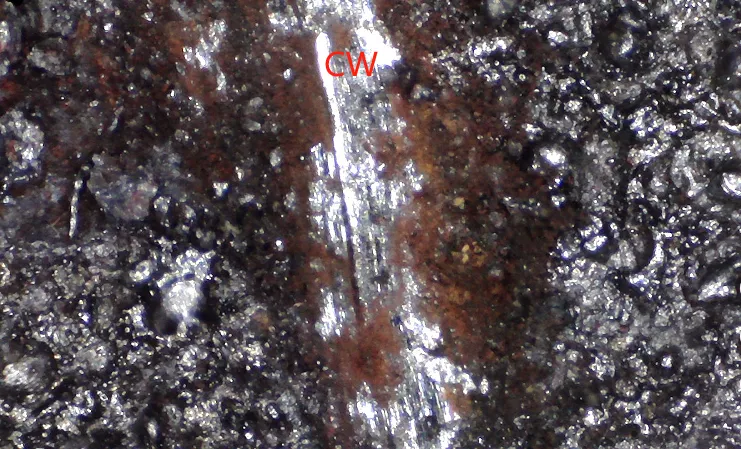

The effect after continuous laser cleaning is as follows:

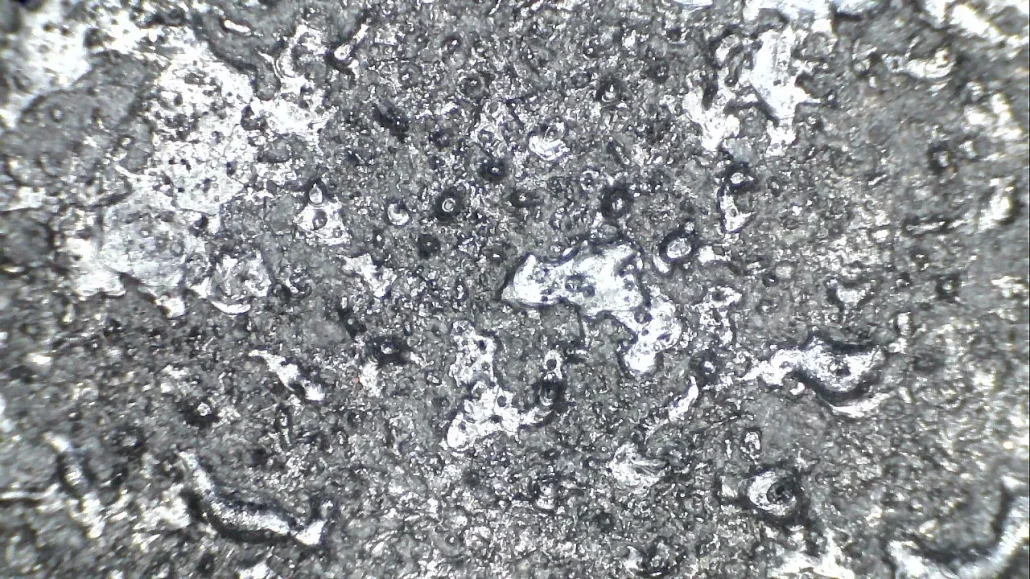

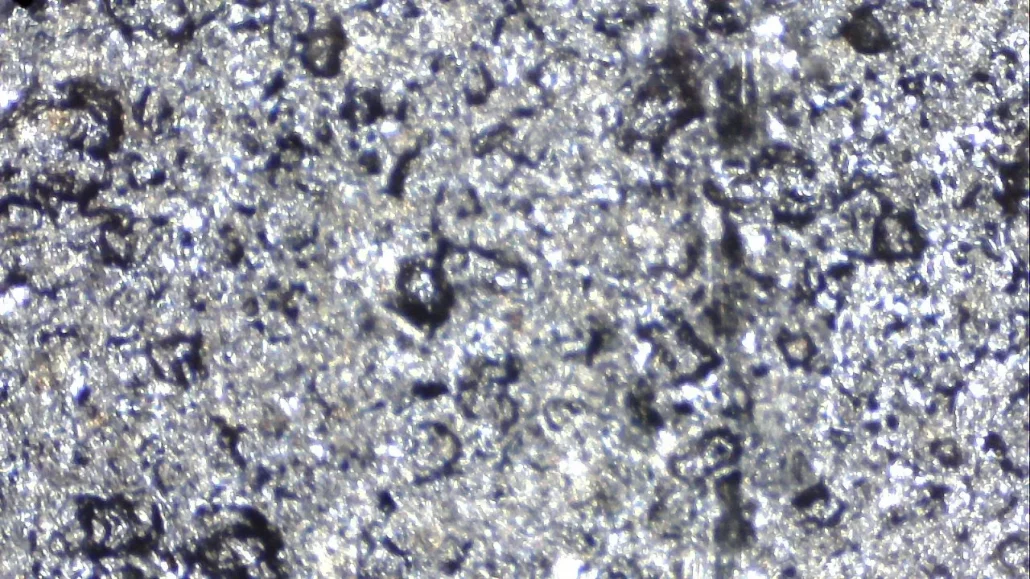

It can be seen that the 2000w continuous cleaning machine removes most of the rust at 30mm/s, and the effect before and after cleaning is quite obvious. We use an electron microscope to randomly select two points for detection as shown in the following figure:

As shown in the above figure, visually all surface rust has been basically removed. We will perform a hard object scratch test at the end of the article to see if the underlying rust has been removed.

3. Rust Removal Test Using Pulse Laser Cleaning

With the parameters set to an output power of 300 watts, a frequency of 35 kHz, a pulse width of 500 ns, and a cleaning speed of 30 mm/s, let’s conduct another test on the effectiveness of the pulse laser cleaning for rust removal.

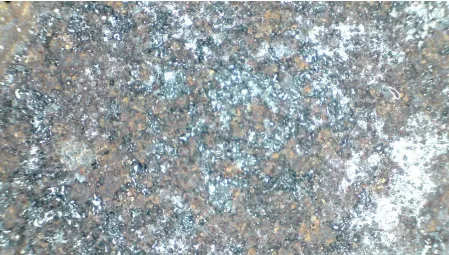

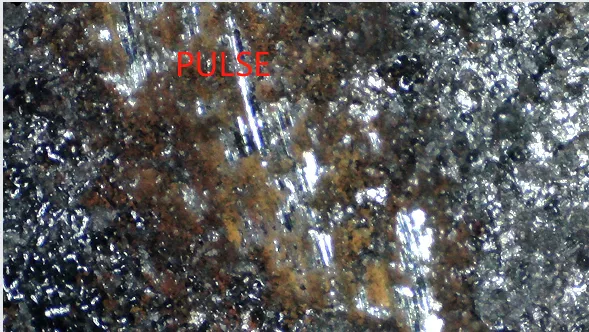

The cleaning results are shown above:

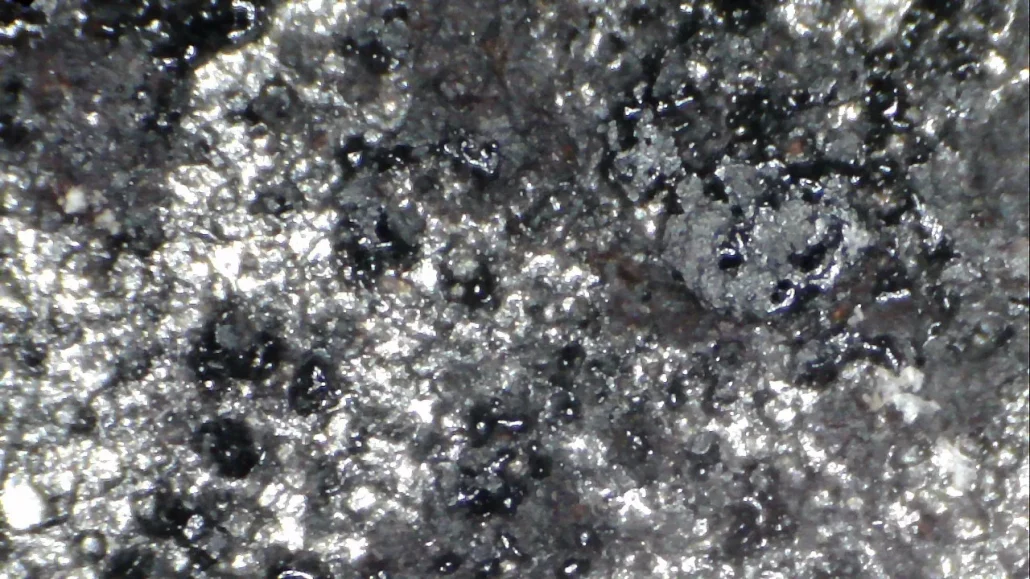

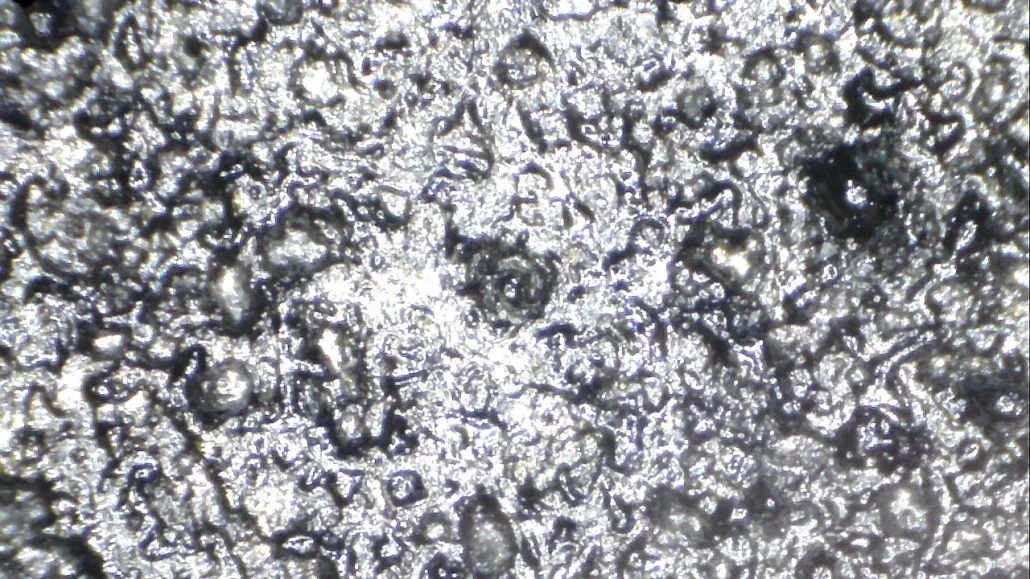

It can be seen that the 300W pulse cleaning machine, operating at 30mm/s with a single laser scan, removes most of the rust, which is more thorough than continuous laser. We randomly select two points for inspection use an electron microscope, as shown in the following figure:

As shown in the above image, visually, all surface rust has been effectively removed, and the color is close to the original metal color, indicating that the rust has been thoroughly removed.

If the cleaning speed is slowed down, the removal effect will be better. Similarly, we will conduct a scratch test on a hard object at the end of the article to verify if the underlying rust has been cleaned.

4. Rust Removal Test Using Composite Laser Cleaning

Finally, let’s test the composite laser cleaning effect on removing rust.

With the parameters set to a 2000w continuous laser, a 300w pulse laser, a 1.5 mm spacing between the two lasers, and a cleaning speed of 30 mm/s.

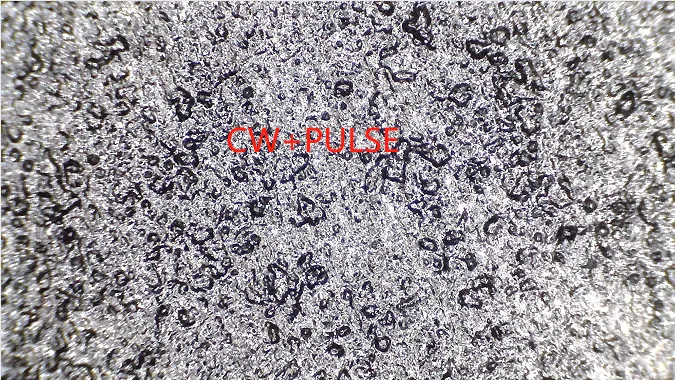

The rust removal results are shown above:

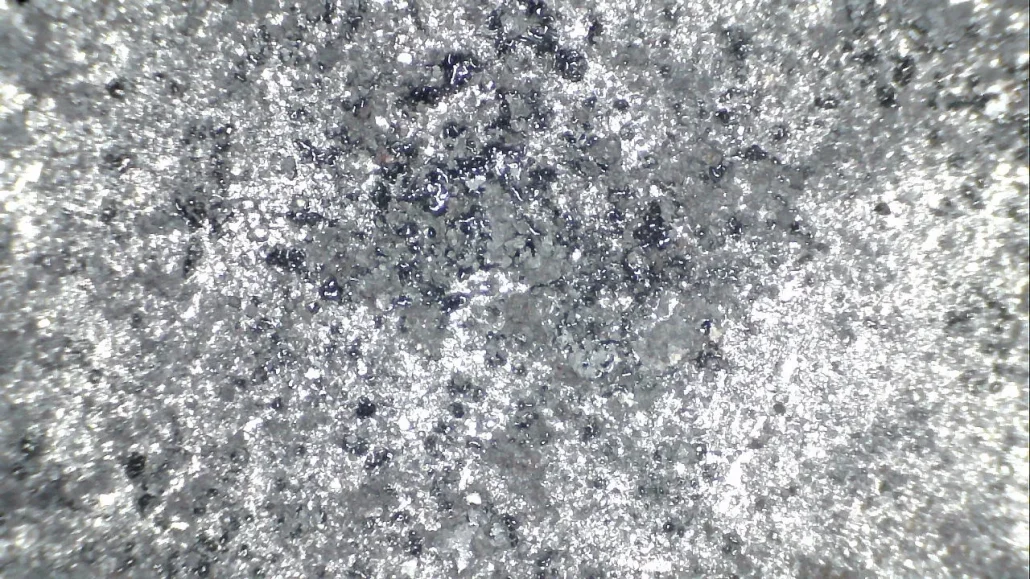

Visually, the composite cleaning result is closer to the original metal color, and the cleaning effect is the best. Also, we randomly select two points to observe under a microscope.

Compared to previous methods, the two randomly selected points appear closer to the original metal color, indicating that composite cleaning is a more thorough method for rust removal.

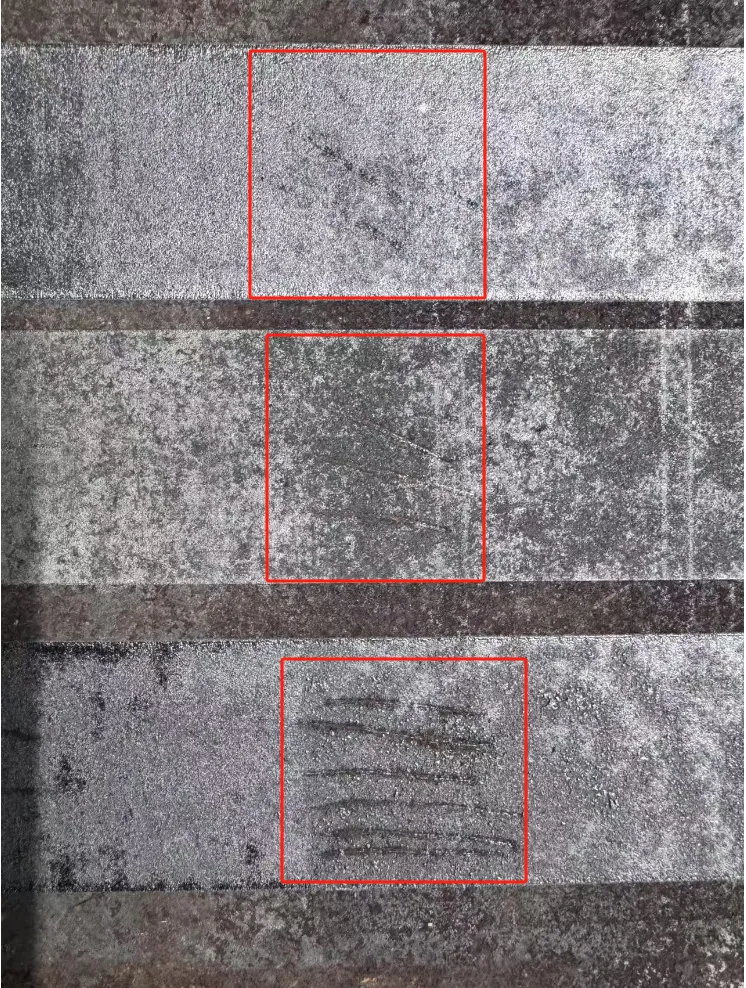

5. Scratch Test to Verify Rust Removal Effectiveness

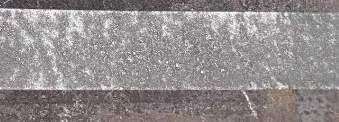

We randomly select locations on the surfaces after the three groups of cleaning, and use a screwdriver to scratch the surface, as shown in the following figure:

It can be clearly found by comparison that there will be rust on the bottom layer of the continuous laser. There is a small amount of rust on pulsed laser. There is almost no rust on the composite after cleaning, which indicates that the cleaning effect of composite laser cleaning is better than that of pulsed laser.

Continuous laser cleaning: Rust traces remain at the bottom of the scratches. Pulsed laser cleaning: Minimal rust appears, significantly less than with continuous laser cleaning.

Composite laser cleaning: Almost no rust is visible, demonstrating superior cleaning effectiveness.

This confirms the performance ranking:

Composite Cleaning > Pulse Laser Cleaning > Continuous Laser Cleaning.

The above electron microscope images further confirm this point:

Finally, under 200x magnification using an electron microscope, we observed that at a cleaning speed of 30 mm/s, continuous laser performs the worst in rust removal. The rust on the surface is carbonized, and rust remains in the deeper layers—this is related to the lack of peak power in continuous lasers. In contrast, pulsed laser also shows some residual rust in the lower layers, but it is much lighter in color compared to that from continuous laser cleaning, indicating a better cleaning effect. Pulsed laser can completely remove rust when the cleaning speed is reduced.

The composite cleaning yields the best results, with no rust found in the lower layers, demonstrating that combining continuous and pulsed lasers enables the thorough removal of both surface and deep-layer rust.