In this article–Raycus vs. JPT laser source: how to choose? we will discuss JPT lasers and Raycus lasers.

This article mainly covers the MOPA lasers of JPT’s main production line, Raycus’s best-selling Q-switched lasers, the similarities and differences between the two lasers, and how to choose between JPT lasers and Raycus lasers.

I hope that through this article, you can have a deeper understanding of JPT lasers and Raycus lasers, so as to help you choose the laser that suits you best!

1. Representative laser types of JPT laser and Raycus laser:

Fiber lasers are divided into two working modes: continuous light and pulsed light. The difference between the two laser brands is mainly reflected in the pulsed light.

Pulsed lasers can remove rust, oxide layers and other contaminants without damaging the underlying material.

MOPA (master oscillator power amplifier) and Q-switching are the two main structures of pulsed fiber laser.

This picture shows the JPT laser

JPT laser mainly represents laser type: MOPA laser

This picture shows the Raycus laser

Raycus laser mainly represents laser type: Q-switched laser

2. What is a MOPA laser?

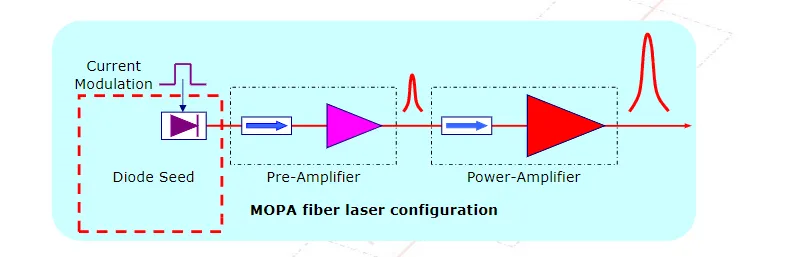

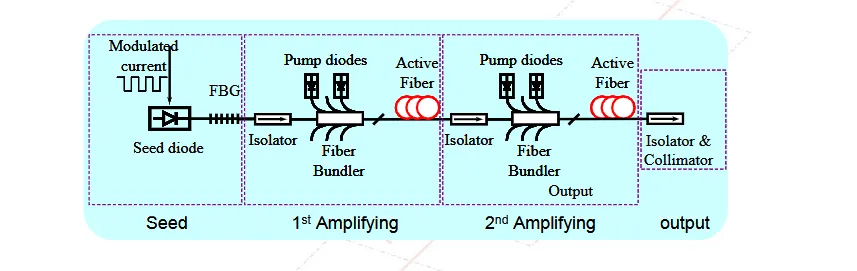

JPT pulse fiber laser adopts the master oscillator power amplifier MOPA (Master Oscillator Power Amplifier) structure.

JPT’s master oscillator uses a semiconductor laser as a seed source, and power amplification is achieved through a fiber amplifier. During the process, the seed laser generates an initial laser signal, which is then amplified by the power amplifier.

2.1 Working principle of MOPA laser:

The master oscillator (seed laser) generates the initial laser signal. Next, the signal is introduced into the power amplifier.

In MOPA lasers, this process is usually automatic, and the signal is transmitted to the power amplifier for amplification through appropriate optical connections. The power amplifier is usually a fiber amplifier with some gain medium added to enhance the signal.

When the initial laser signal passes through the gain medium in the power amplifier, the ions in the gain medium first absorb the energy from the pump light and then release it, thereby enhancing the laser signal.

The MOPA laser can adjust the pulse width and frequency to achieve precise control of the laser output.

2.2 Key features of MOPA lasers:

2.2.1 Adjustable pulse width:

It is easy to confuse pulse width with light output width. In fact, it is completely different from light output width.

Pulse width refers to the duration of the laser pulse, that is, the length of time the laser outputs. It indicates the time interval from the start of laser emission to the stop of laser emission. MOPA-structured lasers allow operators to set different pulse widths, and the adjustable pulse width has shown its advantages in many aspects:

Can clean a variety of materials:

The adjustable pulse width of MOPA lasers allows the laser to optimize energy output to adapt to different materials. For example, short pulses are suitable for materials with high heat sensitivity, such as plastics and thin metals; long pulses are suitable for heat-resistant materials, such as thick metals and oxide layers.

Smaller heat-affected zone:

Shorter pulse width means shorter light output duration and smaller heat-affected zone. In this way, the laser energy can be concentrated on the surface of the material, which is suitable for small areas to play a laser role; on the contrary, longer pulse widths will increase the heat-affected zone and are suitable for cleaning materials over larger areas.

The surface of the cleaned material is smoother:

During the laser cleaning process, a shorter pulse width helps reduce surface roughness, and the laser-cleaned surface is smoother.

This is because a shorter pulse width means that the laser energy can be released in a very short time, generating high peak power.

This fast and intense energy burst can instantly evaporate or remove surface dirt without transferring too much heat to the substrate, reducing the thermal impact effect and basically not causing the material to deform due to high temperature.

2.2.2 High repetition frequency

High repetition rate MOPA lasers have many significant advantages in laser cleaning:

1. Flexible and adjustable:

The high repetition rate of MOPA lasers allows cleaning operations at different power and pulse width combinations. This flexibility allows operators to adjust laser output based on material type and cleaning needs, avoiding over-cleaning or damaging the material surface.

2. Small thermal damage:

At high repetition rates, the time interval between pulses is short, so the laser energy is distributed more evenly. This uniform energy distribution helps to reduce the temperature when using local laser cleaning, and the material surface is too hot to cause deformation or damage.

3. Improve cleaning efficiency:

High-frequency pulse laser can remove oil, rust or coating on the material surface at a faster speed, so the cleaning efficiency is greatly improved. Fast pulses help increase the amount of material removed per unit time, thus speeding up the workflow.

3. What is a Q-switched laser?

3.1 Working principle of Q-switched laser:

Q-switched lasers also use optical fiber as a gain medium, but in Q-switched lasers, there is a Q-switch. Its function is to control the laser frequency, thereby enhancing the laser’s light output energy.

Most of the time, the Q-switch will remain in a high-loss state, which means that most of the laser beam cannot be effectively reflected and enhanced in the resonant cavity. The purpose of this is to prevent the continuous generation of lasers and allow the energy in the gain medium to gradually accumulate.

Over time, more and more energy will accumulate in the gain medium. When enough energy has accumulated in the gain medium, the Q-switch can suddenly reduce the optical loss, allowing the laser beam to be reflected and enhanced in the cavity. This process quickly releases a large amount of energy, forming a short-pulse laser.

3.2 Key features of Q-switched lasers:

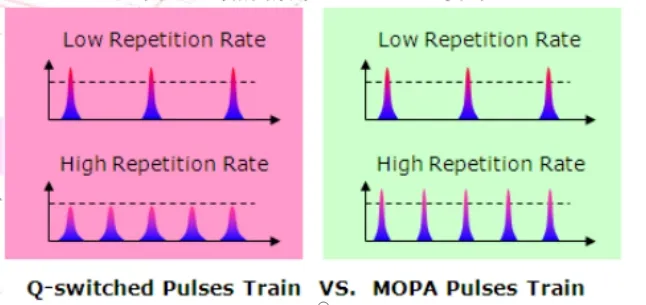

Although the pulse width and frequency of Q-switched lasers are fixed and not as flexible as MOPA lasers, Q-switched lasers still have their own advantages:

1. The laser output energy is more stable:

The pulse width of Q-switched lasers is fixed, usually between a few nanoseconds and tens of nanoseconds. The fixed pulse width can ensure the stability of the output energy. At the same time, it helps to provide short-term high-intensity output in tasks that require high peak power.

2. More durable:

The structure of Q-switched lasers is usually simpler, without a pulse width modulation module, and the failure rate is relatively low. It has good stability and durability in industrial environments and is suitable for long-term, high-intensity working environments.

3. Low maintenance cost:

Q-switched lasers usually adopt a sealed structure, which is not easily affected by environmental factors and has low later maintenance costs.

4. Raycus vs. JPT laser source: similarities

1. Fiber laser type:

JPT MOPA laser and Raycus Q-switched laser are both pulsed fiber lasers. They are just two different structures of fiber lasers, and they can both achieve pulse mode.

2. Pulse output:

JPT MOPA laser and Raycus Q-switched laser both perform laser tasks by generating short pulses with high peak power. It’s just that MOPA lasers have greater flexibility in pulse width and repetition frequency.

3. Power output:

JPT MOPA laser and Raycus Q-switched laser both perform laser tasks by generating high peak power and achieving energy release in a short time.

4. Widely used:

Both MOPA and Q-switched lasers can be used for laser marking because they can provide high-energy pulses, which are suitable for fine marking on materials such as metals, plastics, and ceramics.

5. What is the difference between JPT laser and Raycus laser?

1.Different structures:

JPT MOPA laser:

It consists of a master oscillator (MO) and a power amplifier (PA). The master oscillator controls the pulse width, frequency and waveform, while the power amplifier amplifies the pulse energy.

Raycus Q-switched laser:

By using a Q-switched switch in the resonant cavity, energy is stored in a short time and a high peak power pulse is released.

2. Different pulse width and frequency adjustment:

JPT MOPA laser:

The pulse width and frequency can be adjusted, and in the field of laser cleaning, a wider variety of materials are suitable for cleaning and the efficiency of removing dirt is higher.

Raycus Q-switched laser:

Usually the pulse width is fixed, the laser energy is stable, and consistent and high peak power laser output can be provided.

3. First pulse availability:

First pulse availability usually refers to the first pulse light emitted by the laser when it is started or turned on, which has sufficient energy and stability and can be effectively used for laser cleaning operations.

JPT MOPA laser:

The MOPA structure has first pulse availability. This is because in the MOPA structure, the pulse characteristics of the laser are directly controlled by the master oscillator, and there is no need to wait for energy accumulation or release.

This means that a stable, high-quality first pulse can be output each time the laser machine is turned on, thereby improving the reliability and efficiency of the operation.

Raycus Q-switched laser:

The first pulse of a Q-switched laser is usually not available. Because the energy accumulation in the resonant cavity is not stable enough after the Q-switched laser is first started or re-Q-switched.

Therefore, the laser machine using the Q-switched laser needs to wait after it is turned on, and it cannot emit light immediately, which will affect the laser work that requires instant laser output. However, after the subsequent laser is stable, it will not affect continuous use.

4.Laser light leakage

JPT MOPA lasers are usually not prone to light leakage during use.

This is because the pulse control of the MOPA laser is relatively precise, and the intensity and time of the output laser can be controlled by adjusting the pulse width and frequency. This can effectively avoid unnecessary energy loss.

The working mechanism of Raycus Q-switched laser is different.

It relies on the opening and closing of Q-switched switch to instantly release the accumulated energy. In some cases, Q-switched lasers may experience trace amounts of light leakage, especially if the switching is not precise enough or the control is not ideal.

This phenomenon generally does not significantly affect the laser effect, but may cause slight scattered light in the surrounding environment.

6. Raycus vs. JPT Laser Source: How to Choose?

JPT mainly produces MOPA lasers, while Raycus focuses on Q-switched fiber lasers. Therefore, most JPT lasers you see on the market are MOPA lasers, while Raycus lasers are mainly Q-switched lasers.

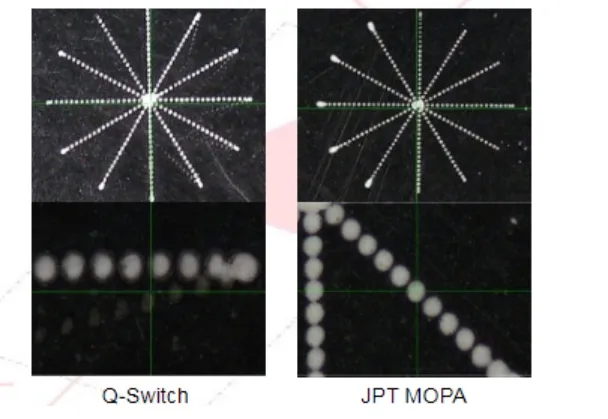

In terms of functionality, MOPA lasers are superior to Q-switched lasers due to the structural differences between the two lasers, and MOPA lasers can complete almost all tasks of Q-switched lasers.

Q-switched lasers perform well in laser marking, especially when high peak power and fine marking are required.

But MOPA lasers perform well in both laser cleaning and laser marking. Not only can they process a variety of materials, but they can also provide higher precision and flexibility.

- MOPA (JPT laser source): more suitable for laser cleaning and marking.

- Q-switched (Raycus laser source): mainly used in laser marking.

| Comparison Aspect | MOPA Laser | Q-Switched Laser | Similarities |

|---|---|---|---|

| Structure | Master Oscillator (MO) + Power Amplifier (PA) | Resonant cavity with Q-switch | Both are two pulse structures of fiber lasers |

| Pulse Width and Frequency | Adjustable | Fixed | Both perform laser tasks using short pulses with high peak power |

| First Pulse Availability | Supports first pulse output without waiting | Does not support first pulse; requires energy accumulation | Both achieve stable, high-quality pulse output after stabilization |

| Laser Output Features | More flexible, suitable for cleaning and precision tasks | Stable output, ideal for high peak power tasks | Both provide high-energy pulses suitable for fine processing of materials like metals, plastics, and ceramics |

| Heat-Affected Zone | Smaller heat-affected zone, enabling more precise effects | Larger heat-affected zone | Both release high energy in a short time for non-contact material processing |

| Application Scenarios | Excellent for laser cleaning and marking, supports a wider range of materials | Primarily used for laser marking with high peak power | Both can provide high-energy pulses for detailed processing operations |

| Maintenance Cost | Slightly higher due to greater flexibility | Lower due to simpler structure | Both are suitable for industrial environments with high stability and reliability |

| Laser Leakage | Precise pulse control minimizes leakage | May experience minor leakage due to switching precision |

Summary

JPT MOPA and Raycus Q-switched pulsed lasers each have their own advantages.

In laser applications, understanding their different performance helps you choose the most suitable laser type to optimize work efficiency, improve material adaptability, and ensure the final display effect.