Dear new and old users of HANTENCNC, thank you for your continued support of our laser cleaning system. To continuously improve user experience, we will conduct a vital system upgrade. This upgrade will be officially launched on March 1. It will bring you more efficient and stable services.

What Highlights Have Been Updated?

Performance Improvements

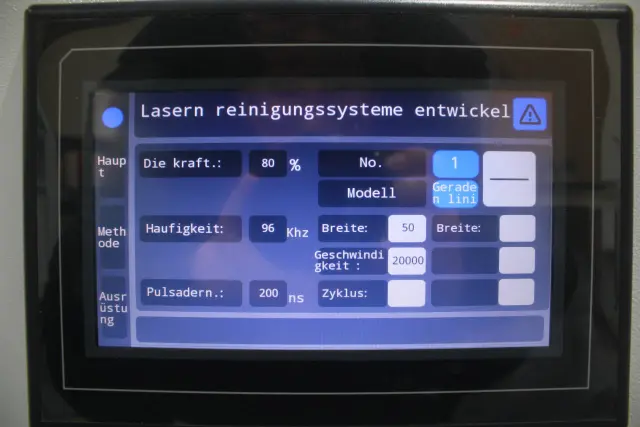

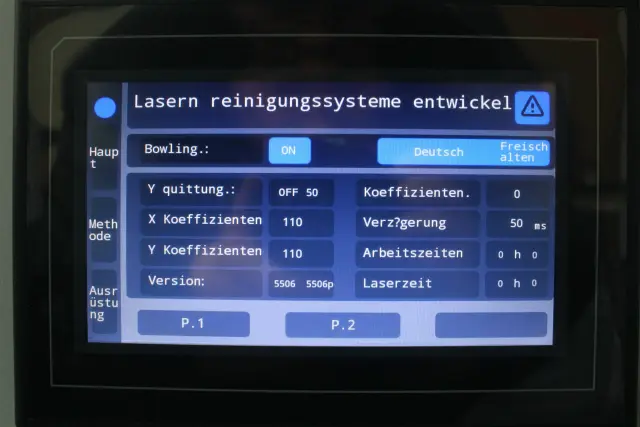

We have conducted in-depth system optimization of the machine. The HMI interface lets you quickly call up preset sets of process parameters via six process options. This is intended to improve the overall performance of the cleaning system. You will experience faster response and a smoother operating experience.

The equipment can customize 100 sets of process parameters at the same time. According to actual needs, 1-21 groups of parameters can be set for specific process description reference. In actual production, the corresponding process parameters are called for the product in a targeted manner.

New features Introduced

We’ve introduced some useful new features. Operators can customize process parameters. According to the parameter group serial number and the corresponding process reference description. Enter the required parameter group number. These features can meet changing user needs. They will enhance your operational flexibility in the cleaning system. They will also allow you to conveniently complete cleaning.

User Interface Optimization

We’ve redesigned the user interface. The new interface is more intuitive and friendly. Whether you’re a new user or an experienced user, you’ll be able to find the features you need more quickly. Operators can use the cleaning system more efficiently.

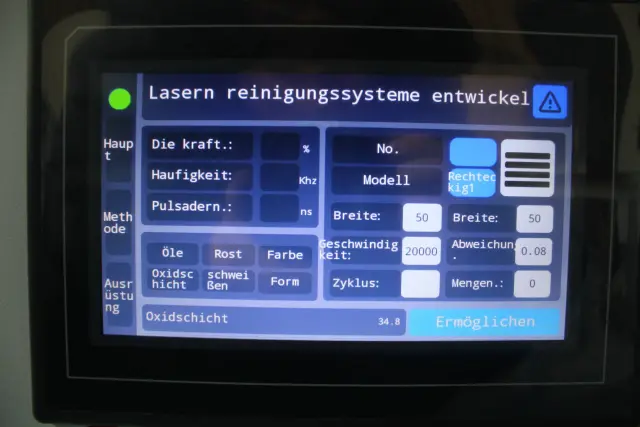

The interface’s graphical reference allows the scanning form and parameters to be quickly judged and adjusted. A corresponding relationship exists between the reference pattern and the actual scanned pattern. The scanning pattern style suitable for workpiece cleaning can be selected intuitively through the operation interface.

Graphic reference interface

Real-time preview

Parameter adjustment

Clear correspondence

User-friendliness

Save and load configurations

Improved Security

-

The information is clear and concise: Ensure the information on the alarm page is clear and concise and can quickly convey critical information. These include alarm time, alarm type, equipment location, and other information.

-

Real-time update: Ensure that the alarm page can be updated in real time to reflect the latest changes in equipment status. This facilitates timely response to issues and reduces the likelihood of production disruptions.

-

Alarm history: Provide alarm history records for fault and trend analysis. This helps identify long-term performance trends of the equipment and possible potential problems.

HANTENCNC is Willing to Listen to Your Suggestions

Your feedback is important to us. Please get in touch with our customer service team if you encounter any problems after updating or have any suggestions. We will listen to you and continuously improve the system to meet your needs better.

Thank you for your patience and understanding, and we look forward to bringing you a better cleaning experience with the new system!