Laser welding is now popular in many industries because of its extensive benefits. The handheld laser welder will be your first choice if you are working with metal welding. Whether you are working with door & window guardrails, furniture, or casting, a laser welder offers the best service. It also helps you upgrade your production.

Why do a lot of people choose laser welding? Efficiency, welding quality, and safety are the primary reasons for choosing it.

Worth mentioning that the handheld laser welder machine is very user-friendly. Easy to operate, even for a beginner.

Today, we will teach you how to use a handheld laser welding machine and how to set the parameters. You will be the next welding master after reading this article.

How to Use a Laser Welder?

Laser welding is comparatively easier than other traditional methods. As mentioned, a laser welder is preferred because of its efficiency, safety, and variety of functions. This tutorial lets you quickly understand how a laser welder works.

Safety

When we design the machine, safety is our primary concern. All the laser devices from HantenCNC are equipped with the highest safety standards.

You can power the laser welder and ensure the water chiller runs well. There are four alarm indicators on the laser welder control panel, which alert the working situations.

- The cooling system alarm illuminates when there’s a malfunction or insufficient performance in the cooling system. It shows that your machine is at optimal operating temperature.

- The blowing alarm indicator alerts you to issues related to the blowing mechanisms. It is crucial to ensure proper material handling and debris removal during the welding process.

- The laser alarm warns of faults within the laser system.

- The galvanometer alarm signals problems with the galvanometer.

Press the diagnostic button on the display to check the machine’s circumstances and see if any alarm goes red.

We also designed double safety protection for our machine. You need to turn on the safe lock and clamp the ground wire to the metal object before taking any further action.

Otherwise, the machine will not start.

Setting Parameters

Now, you are back to the control board to set the parameters. You know, setting parameters is always the most frustrating part. That’s why we have saved all commonly used settings in the laser software.

Common metals like carbon and stainless steel are all listed in the software. You can select the different thicknesses by simply clicking it. So, don’t worry if this is your first time.

Of course, you can modify the setting as well. Laser power, wobble length, and feeding parameters matter to your welding operation and affect the most.

Laser Power Setting

The laser power directly determines the welding effect. In this discussion, let’s use a 1500W fiber laser generator. You can set the laser power at different watts to compare the welding penetration directly.

Let’s set it at 500W first and see the effect. The weld penetration is excellent, right?

Now, input 200W laser power and see what will happen. Reducing the power will result in a narrower pass. If you need to weld thicker metal, you want the laser energy to go deeper, so go with the higher power.

| Metal | 500W | 1000W | 1500W | 2000W | 3000W |

| Aluminum | 2mm | 3mm | 4mm | 5mm | 8mm |

| Stainless Steel | 3mm | 5mm | 7mm | 8mm | 10mm |

| Carbon Steel | 6mm | 10mm | 12mm | 16mm | 20mm |

| Copper Plate | 2mm | 3mm | 4mm | 5mm | 8mm |

Table 1: Highest Weld Thicknesses for Different Power

We make handheld laser welders from 1000W to 3000W. If you visit the website linked, you will find different types of laser welders. Based on your application needs, you can select the correct type. You can also consult our customer support team to learn more about selecting the correct type.

Wobble Length Setting

We all know the stability of the laser generator determines the quality of laser welding. Choose a suitable fiber laser source based on your production.

The wobble length determines how wide your weld bead can be, and you can set it up to 5mm.

First, let’s put the wobble length as 2mm and see the effect. The welding width is small. This is suitable for thin metal welding.

Then, let’s change it to 3mm and 5mm. And you got two wider weld passes. If you want to weld thicker metal, we recommend setting the wobble length higher. It guarantees a larger beam diameter.

In addition to the thickness of the metal piece, the wobble length should also be set to match the thickness of the wire.

Wire Feeding Setting

The wire feeder supports the wire diameter from 0.8mm to 1.6mm. You can set the feeding parameters like speed and feeding delay time. Welding thicker metal usually requires a longer feeding delay time. You can choose to feed the wire automatically or manually.

And you can set everything in the control panel. Some welders only support editing the setting on the wire feeder, which is not so convenient. Hanten CNC laser welders come with the latest technology. Therefore, you can get all the control features in the control panel. Using Hanten CNC laser welding equipment is also convenient.

Start Welding

The basic setting is done well. Let’s take out the metal workpiece and welder gun for the real action. Typically, you can select spot welding on the control board. You need to spot weld the parts in place, generally at the ends of two sides.

Then, you can select continuous welding mode and start metal welding. It’s really easy to use and convenient to move and meets various welding methods, such as stitch welding, tailored blank welding, and fillet welding.

You know laser welding machines are outstanding in welding precision and efficiency. Usually, you can weld metal from 0.3-6mm. We wrote another article talking about the structure of the whole machine.

This article will help you understand laser welding machines more comprehensively.

Other Functions

Besides the common continuous mode, you have a pulse mode similar to TIG pulse welding. And to protect your workpiece from splash and oxidation, you can change the gas delay time on and off in the software.

That’s significant for your safety and getting a clean welding effect.

The software in the HantenCNC laser welding machine supports multiple languages. Standard languages are Chinese, English, Turkish, Russian, and Deutsch.

There are other functions as well. The whole system is user-friendly. You can change laser frequency, laser duty, wobble frequency, diagnose function, and more.

Troubleshooting Various Laser Welding Issues

You may sometimes encounter a few issues during laser welding. Don’t worry! If you are a beginner, you must know how to solve these issues. You can also seek professional assistance if you get stuck in any problems. Otherwise, you can contact our customer support team for a reliable solution.

Incomplete penetration

It occurs due to the failure of the laser beam. You may find in weak or incomplete welds. To address this, adjust the laser parameters and test whether it gives the appropriate result. You check for standard power and pulse duration in the manufacturer manuals.

Porosity

After welding, you may find some tiny bubbles within the weld. It is called the porosity of the laser welding. It may weaken the joint integrity. Porosity typically happens due to the contaminants on the workpiece surfaces. Therefore, you must clean the workpiece before laser welding. You can also optimize the gas flow rate during the process.

Cracking in laser welding

It may occur due to rapid cooling rates or excessive thermal stresses. To mitigate this problem, you can employ preheating techniques. In addition, you can also adjust welding parameters to control heat input. It can minimize cracking tendencies.

Overheating

This is one of the most common issues. Overheating may lead to excessive melting or distortion of the workpiece. It can degrade the weld quality as well as structural integrity. Therefore, optimize laser parameters and control the welding speed. We hope you can regulate heat input correctly and prevent overheating problems.

Frequently Asked Questions

How thick of metal can a laser welder weld?

Using a 1000W laser welder, you can weld metals from 0.5mm to 3mm in thickness. Consecutively, using 1500W from 0.5mm to 4mm, 2000W from 0.5 to 5mm and 3000W from 1mm to 8mm.

Is laser welding as strong as normal welding?

Laser welding can make welds just as strong as those made in other ways. It gives you exact control over how much heat goes in. Because of this, it can reach deep depth with little distortion.

Should I buy a laser welder?

Picking laser cutting is a great choice. In fact, it does make the weld end nice and clean. It’s almost impossible to get this level of accuracy and low thermal distortion using traditional methods.

Conclusion

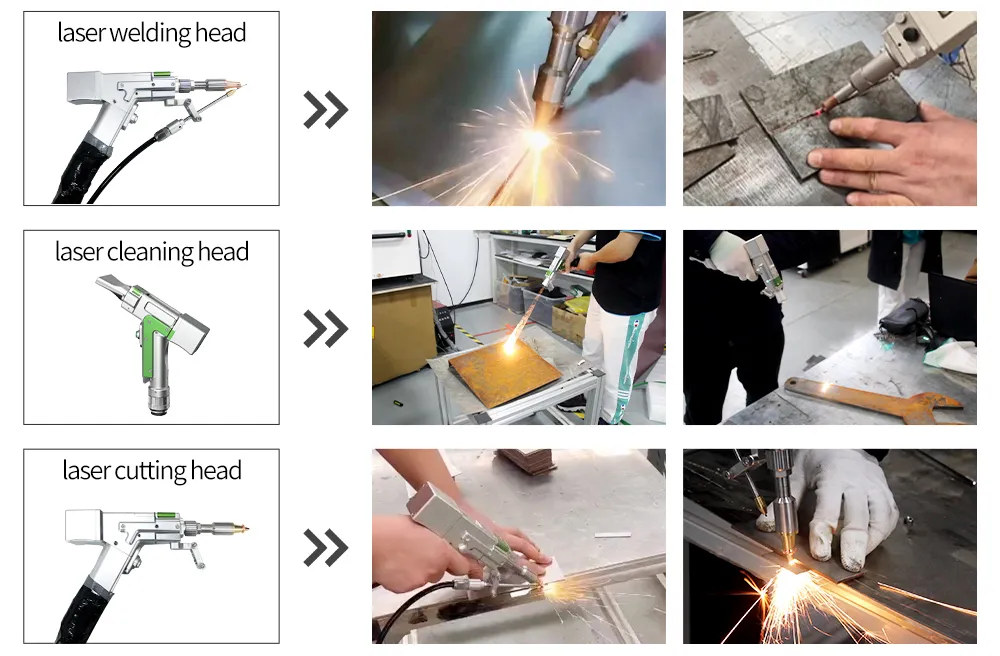

A laser welder machine typically has various components. For example, laser generators, laser guns, wire-feeding guns, displays and software. Using laser welding software is easy. It doesn’t require complicated manual inputs. It comes with a few standard settings. Although you can change these settings based on your unique requirements.

Hanten CNC is a leading manufacturer of laser welder machines. We produce laser welders with different features and specifications. Based on your project requirements, you can choose the best option for your application.

Let us know your requirements; we will recommend a proper laser welding machine and give you a detailed guide.

Also, you can leave your questions or insights in the comment. If you are wondering whether you should choose a handheld laser welder or not, don’t miss the next updated article. Contact us for more information.