The laser marking machine is small in size. It saves time and labor and is easy to operate. High cost performance. Laser marking machine has gradually replaced other processing marking equipment on the market. It also meets the production and development needs of many manufacturers. Many people hesitate to buy laser marking machines. The higher the power used by the laser marking machine, the better the effect. But is it really the case?

Today, the editor of HANTENCNC will show you how to choose the power of the laser marking machine? Here are some examples of the application of three laser marking machines commonly used in the market and how to choose their power.

The laser marking machines commonly used in the market today are:

-

UV laser marking machine

Generally, the power of ultraviolet laser marking machine is 3 watts. 5 watts. 10 watts. 15W, etc. The ultraviolet laser marking machine is mainly used for plastic cosmetics. Medicine. Food. PCB。 QR code. Metal surface coating. Plastic button. ornament. Charger plug, etc. The higher the power, the higher the price. 3W-5W is now widely used in industry. In particular, their prices are moderate. It can meet most machining marking requirements. Ultraviolet laser marking machines of 10 to 15 watts are too expensive. It is mainly used for high-precision cutting and drilling.

-

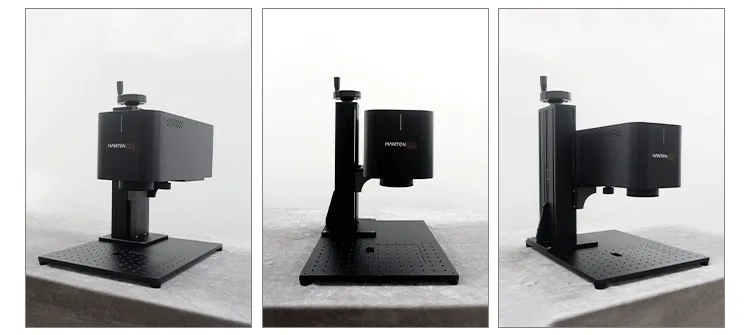

Fiber laser marking machine

The power of fiber laser marking machine is generally 20W.30W.50W.60W.80W.100W. Laser marking machine can mark all metals and some non-metals, such as ABS, epoxy resin, etc. If you need to mark more materials, you can contact our WhatsApp or email.

Usually, a 20W laser marking machine can produce perfect results. However, for some parts that require deep marking or people who want high marking efficiency, it is recommended to use a high-power laser marking machine for marking. You can tell our sales manager your needs and marking effect, and we will recommend suitable machines to you according to your needs.

In addition, our fiber laser marking machine has many styles to choose from: mini-split type, portable integrated type, desktop type, hand-held type, small koala type, flying type and so on. Whether it is small parts or large machinery, there are suitable machines to choose from, and you are welcome to come to consult us at any time.

-

CO2 laser marking machine

The power of CO2 laser marking machine is generally 10 watts. 30 watts. 50 watts. 60 watts. 100 watts. 150 watts. 275 watts, etc.

Carbon dioxide laser marking machine is mainly used for marking and cutting of non-metallic materials. For example, leather. Wood. Plastic. silica gel. Composite sheet. Glass, etc. Generally, the power selection of CO2 laser marking machine is determined according to the effect demand and product material of the marking product. In this case, you can send us a private message. Hanteng can arrange free proofing for you and recommend the one you really need.

Optical fiber marking machine has three major components: laser, control card and marking head.

-

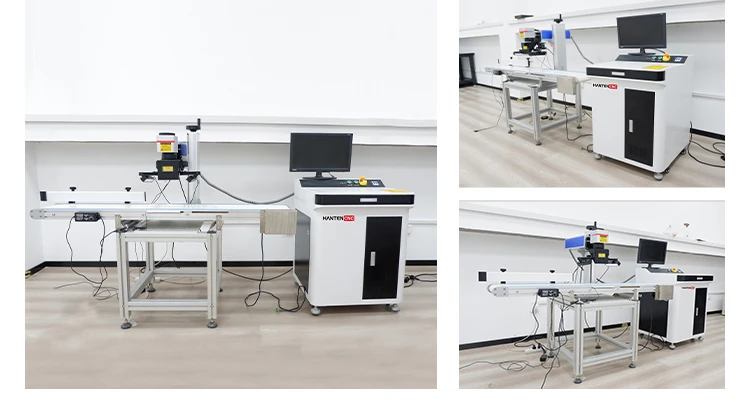

CCD visual positioning laser marking machine

CCD visual positioning laser marking machine uses the principle of visual positioning. It is mainly aimed at the difficulty of material supply caused by the difficulty of fixture design and manufacturing in batch irregular marking. Poor positioning. Slow speed. It can be realized only within the processing range of laser marking scanning galvanometer. This enables accurate marking. Even if the position is different each time. There is no problem with the machining position. It is applicable to heavy workload. Product positioning is difficult. Workpiece diversity and complexity such as capacitance. IC card. Small screws. Jewelry, etc.

-

3D laser marking machine

The traditional two-dimensional laser marking machine adopts the back focusing mode. It is only applicable to plane marking within the specified range. 3D laser marking machine adopts advanced digital three-axis dynamic focusing technology. With 3D surface 3D laser marking function. It breaks the limitation of traditional optical fiber laser marking machine. The requirements for surface flatness of the machined object are greatly reduced. The processing effect of 3D laser marking machine is more colorful. It can realize laser marking more accurately on curved workpieces. In addition, defocusing does not occur during processing. You can even freely work with complex surfaces.

Many customers may purchase laser marking machine equipment for the first time, which is a novice. Today, HANTENCNC will share how to disguise himself as an “old hand”.

In fact, this is very simple. There are three core components of the optical fiber marking machine: laser, control card and marking head.

What is the brand of laser?

Control card:

Marking head:

Choose the right machine according to your needs

For different materials and marking needs, we have different laser marking machines to choose from. Such as CO2 laser marking, fiber laser marking and UV laser marking, flying laser marking machine, etc.

It is recommended to conduct proofing test on the machine. To check the effect. And choose a more convenient after-sales company. The laser marking equipment produced by HANTENCNC is very good. Visual positioning system is very intelligent and convenient.

How to choose a laser marking machine

Now the laser marking machine has been widely used in all walks of life. It has almost become an indispensable process on the product production line.

-

Beam quality

Including output quality and mode stability. Some marking machines have divergent output beams. The marking effect is poor. Or it is not stable when marking for a long time. The product production efficiency is reduced.

-

Practicability

When selecting a laser marking machine. Be sure to have a targeted understanding of its functions. Whether it is applicable to its own product processing and stability. Because the output power is different. Therefore, the effect is different for different products. Proofing must be carried out before purchasing laser equipment.

-

Maintenance

Have good fault diagnosis measures. Generally, when there is a fault. Users can perform troubleshooting by themselves.

-

Operational aspects

The simple and clear operation interface is easy to use. And it is not easy to damage the laser caused by operation errors.

-

Continuous working capacity

For all industries. The working environment is different. Pressure resistance. The ability of continuous operation without any influence in terms of corrosion resistance.

Choose us

HANTENCNC has focused on laser marking for more than 10 years. With rich industry experience. I hope you can choose your own laser marking machine. It is more secure to choose reliable brand manufacturers!

If you have more questions, you can contact me by phone via private mail. In Chinese, it means that Hanteng will tell you everything about your problems.

Therefore, the power of the laser marking machine is determined by the product. Only when the laser marking machine is used to test the sample, can the power used be determined. It is not that the higher the power, the better. Only the most suitable power is good. For those who do not know much about laser equipment, it is better to buy according to the recommendation of the supplier. The best thing is to buy the right one.