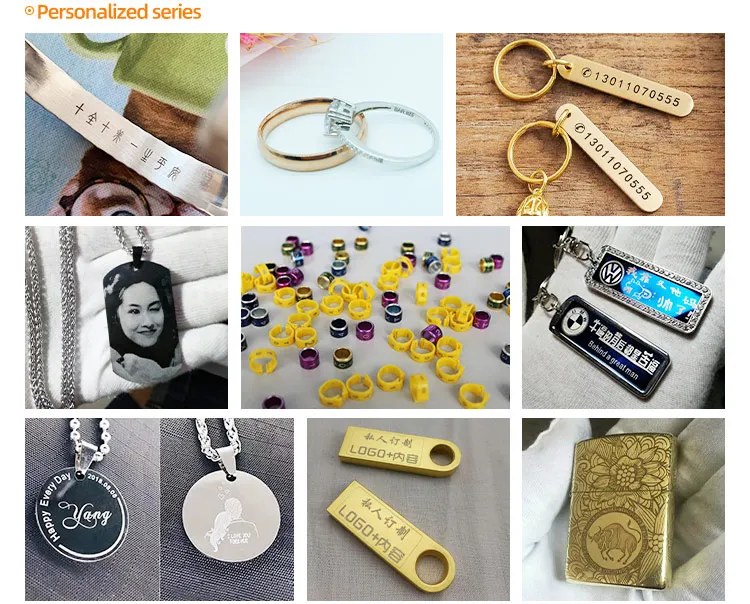

People love jewelry. As you know, it comes with many exquisite patterns. You may wonder how these beautiful patterns are made. Laser cutting is one of the famous methods here. GLE VS QCW is a critical discussion regarding silver cutting.

GLE pulsed and QCW fiber laser engraving is two trendy methods in the jewelry industry. Both methods offer precision and efficiency in cutting. However, GLE is famous for its simplicity, less upkeep, and cost-effectiveness. On the other hand, QCW offers higher-quality cuts. So, the choice mainly depends on your specific requirements.

This article mainly highlights all these parameters to determine the best choice for your job. It can be your best guide when choosing between GLE and QCW fiber laser cutters.

Understanding GLE Pulse Laser with Galvanometer for Cutting

GLE stands for Galvo Laser Engraving. This type of laser machine uses a galvanometer to improve the beam quality. A galvanometer is a device with rotating mirrors. Its main job is precisely directing the laser beam around the material surface.

Pulsed fiber laser is another core component of GLE techs. As the name suggests, it creates a pulsed output laser power. The pulse rate may vary from device to device. However, this pulsing technically controls the amount of output power. Overall, it reduces HAZ on the material surface.

- Galvo laser engraver provides improved precision.

- The pulsed features in the fiber Galvo laser reduce thermal damage.

- Galvo laser engraver offers consistent quality.

- It is cheap and needs less maintenance.

You may find GLE pulsed fiber laser applications in the jewelry industry. When it comes to making silver jewelry, this tool works very well. We will see its suitability in the comparison section.

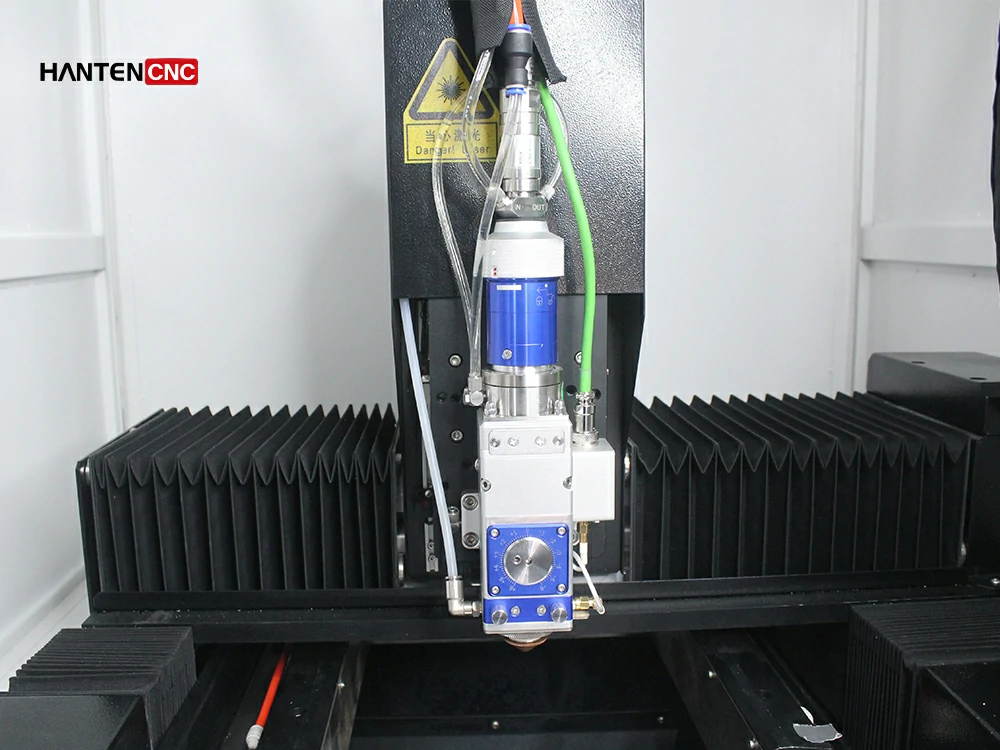

Understanding QCW with Cutting Head for Cutting

QCW stands for Quasi-continuous wave. This technology combines pulsed and continuous waves—like 2 in 1. That’s why people call it a hybrid laser system.

Quasi Continuous lasers deliver high-peak-power pulses. They can also provide continuous mode, making them very versatile.

These laser devices usually need auxiliary gases. These gases are mainly required to ensure a high-quality cut and smoother edges. However, it is reasonably the most crucial benefit of QCW fiber laser engravers.

These hybrid lasers are widely used in various sectors. They cut and etch different stones, metals, or jewels in jewelry. Similar uses can be seen in manufacturing, electronics, and fine metalwork.

GLE VS QCW: Which Laser Is Better for Silver Cutting?

Why is it essential to choose the correct method between GLE and QCW? GLE VS QCW comparison allows you to learn more about them.

First, the proper method gives you the best output compared to your project needs. Second, it saves some of your budget and makes profitable outcomes. Third, it offers reliability for long-term use.

Introduce Laser Machines for the Comparison

We will use two popular laser devices to make the comparison more manageable. These two methods are widely popular for silver cutting.

GLE Pulsed Fiber Laser 50W

The GLE pulsed Fiber Laser 50W is a trendy laser device widely used worldwide. It uses a galvanometer for accurate beam positioning, hence the name GLE. This Fiber Galvo laser engraver offers a high pulse repetition rate. The controlled pulse duration ensures excellent quality of the laser beam.

QCW Fiber Laser 150W

The QCW Fiber Laser 150W offers a different approach. As you know, QCW stands for Quasi-continuous wave. It is a combination of pulse and continuous power. It usually provides higher peak power and longer pulse duration. These types of devices are suitable for high-precision cutting.

GLE VS QCW: Speed

Let’s take a 1mm thick silver plate and cut a 5mm x 5mm round bar. Let’s first use a GLE 50W pulsed fiber laser cutter. This laser device will repeatedly cut the silver plate layer by layer. We have already run an experiment and found it takes approximately 26 seconds.

Let’s take the same plate and cut the same round bar. The QCW 150W laser cutter takes only 3 seconds.

Our observation: The QCW laser cutter offers a faster solution than the fiber Galvo laser.

GLE VS QCW: Efficiency

We’ve seen that GLE pulsed fiber lasers need 26 seconds to finish silver cutting. The galvanometer scans more than once during the process. So, to cut 5mm diameter and 1mm thick silver, GLE pulsed fiber lasers showed low efficiency.

Our observation: QCW fiber lasers are more efficient than pulsed Galvo scanner laser engraver.

GLE VS QCW: Cut Quality

GLE pulsed fiber lasers can cut any design on silver plates. The cut quality is also satisfactory.

However, QCW fiber lasers use auxiliary gas to cut metal plates. This method proved fast, efficient, and better at cutting silver.

Our observation: QCW fiber lasers are suitable for smoother edges and precision cuts.

GLE VS QCW: Assist Gas

The GLE pulsed fiber laser cutter requires no gas to assist during silver cutting. It is simple to use: Plug it in and play.

On the other hand, the QCW fiber laser cutter needs an assist gas. The use of assist gas in laser cutting usually improves the cut quality. However, the QCW 150W laser cutter uses oxygen to assist with silver cutting.

Our observation: The GLE 50W pulsed fiber laser cutter is better, considering its simplicity. However, QCW fiber lasers are better, considering their cut quality.

GLE VS QCW: Maintenance

GLE pulsed fiber lasers usually have fewer moving parts. In silver cutting, this method gives consistent output without any assist gas. Thus, the GLE 50W pulsed laser needs less upkeep. Because of this, these laser devices offer longevity and durability.

On the other hand, QCW fiber lasers typically have more moving parts. Because they use oxygen, they offer a better-quality silver cutting. However, they need more upkeep.

Our observation: The pulsed Galvo laser machine needs less maintenance. They are more durable.

GLE VS QCW: Cost-effectiveness

GLE pulsed fiber lasers are easy to operate and don’t require consumables in the cutting process. Their equipment also doesn’t require maintenance. Overall, the initial cost of GLE pulsed fibers is more economical.

On the other hand, QCW fiber lasers require consumables in the cutting process and maintenance. Their initial cost is higher than that of GLE.

Our observation: The initial cost and TOC of GLE pulsed fiber laser are cheaper than QCW lasers.

Frequently Asked Questions

How Big Are Galvo Laser Spots?

Galvo laser spots are the focused points of laser beams. A Galvo scanner mainly directs these laser spots. These scanners use rapidly moving mirrors to steer the laser beam around the material’s surface. The spot size may vary from device to device. It mainly depends on focal length, laser wavelength, and beam quality. However, usually, this spot size ranges from 180μm to 1064nm.

How Do You Focus a Galvo Laser on A Flat Surface?

Focusing a Galvo laser on a material surface is simple. First, raise the Galvo head as much as possible. Then, start an engraving process. It’s better to repeat the process and have enough time to tune the Galvo laser position. Bring the Galvo Head down until it starts to make noise.

Now, this is the most crucial step. Continue to lower the head until you have the highest level of noise. If the noise stops, raise it back and tune the position to the highest noise level. This quick method is how you focus a Galvo laser on a flat surface.

What Is the Difference Between CW And QCW Lasers?

Continuous wave (CW) lasers emit the same uninterrupted laser beam. CW lasers are ideal for use when people need steady and constant power. QCW stands for Quasi Continuous Wave. It emits laser pulses with higher peak power over short durations. It is a combination of both CW and pulsed lasers. Technically, it can achieve higher precision and efficiency in cutting.

Summary

Are you ready to decide between GLE and QCW? As this article discussed, six factors mainly come into play in this case.

First, speed tells you how quickly you can finish a task. Second, efficiency determines whether you need consumables and how much it costs over time. Third, precision tells you how well your laser machine can work. Fourth, maintenance needs affect long-term reliability. And finally, cost talks about your budget and profits in business.

The table below outlines the differences between GLE and QCW laser devices. Note that which one is better depends on what you need.

| Feature | GLE Pulsed Fiber Laser (50W) | QCW Fiber Laser (150W) |

| Ease of Use | Very simple to use in the cutting process | Relatively complex cutting with graphic control |

| Cutting Speed | Slower Cutting Process (to cut a 5mm x 5mm x 1mm plate takes 26s) | Faster cutting process (to cut a 5mm x 5mm x 1mm silver plate takes 3s) |

| Efficiency | Low efficiency (for higher efficiency, choose GLE 100W) | Higher efficiency for deep or precise cuts |

| Assist Gas | Assist gas is not required | Need assist gas (often oxygen assisted) |

| Maintenance | Lower maintenance | Higher maintenance |

| Precision | Comparatively lower precision but good quality of cutting | Higher precision and higher tolerances |

| Cost | Lower cost for both initial and operating cost | Higher initial cost and need consumables, increasing TOC |

| Application | Suitable for fine and detailed cut | Ideal for deeper, more intricate cuts |

Contact us today! We manufacture a wide range of laser machinery. Our products’ services include marking, engraving, cutting, cleaning, and welding. You can also contact us for spare parts. If you have any questions, you are always welcome to contact our customer support.