Traditional Argon Arc Welding Introduction

Advantages

- Traditional argon arc welding also has a comparative advantage. The price is low, generally ranging from a few thousand to 20,000 to 30,000.

- Although the processing is relatively rough, the power is stronger than others. It is suitable for load-bearing steel structures with slow welding speeds.

Disadvantages

- The welding thickness is relatively thick, suitable for thick welding plates above 4mm.

- Argon arc welding requires mature welders. And the monthly salary of mature welders starts at least 8K.

Handheld Laser Welding Introduction

Advantages

- The complete set of handheld laser welding equipment is powerful. Ergonomically designed and suitable for various working environments. It has a unique laser safety operation protection function. And it can ensure the operator’s safety when working.

- The operation is easy to learn and quick to use. And the technical threshold of the operator is not high, which saves labor costs.

- Hand-held welding is easy to learn. Ordinary operators can get started in half a day. The monthly salary of an ordinary handheld welder is generally around 4k.

- The speed of a laser welding machine is 10-20 times. Ordinary laser workers can easily operate it, and the working environment is relaxed. The salary of one argon arc welder can employ three laser operators.

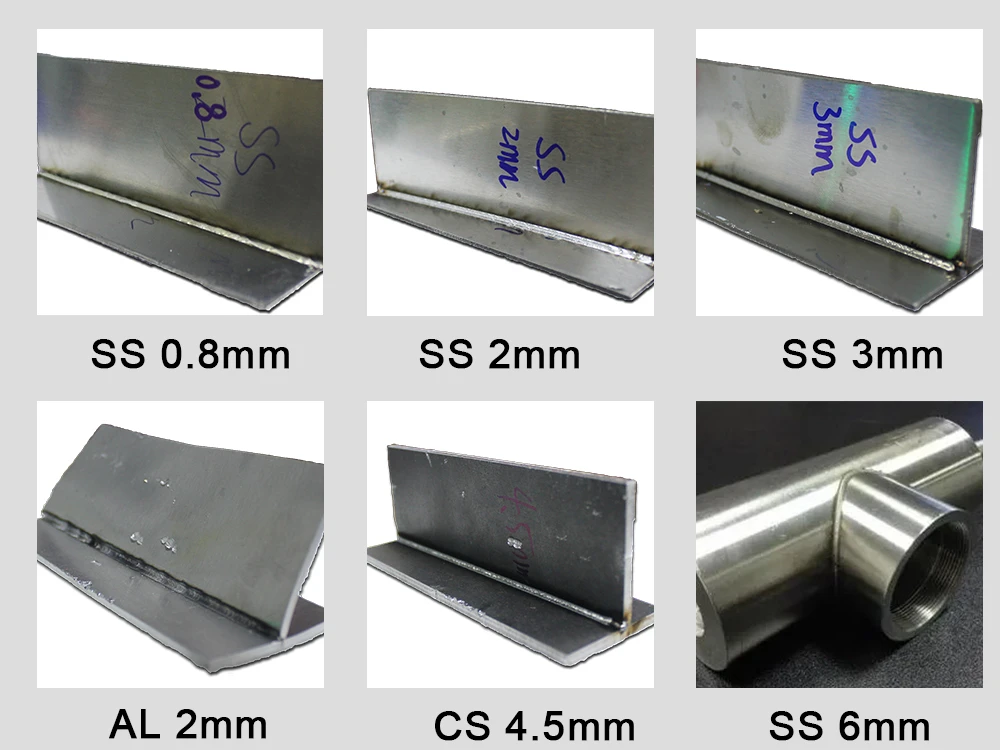

How Thick Can Laser Welding Machine Weld?

The greater the thickness of the welded workpiece, the greater the power of the selected laser welding machine should be.

- 1000W laser welder machine: the welding effect is good for plates with a thickness of less than 3mm.

- 1500W laser welder machine: the welding effect is good for plates with a thickness of less than 5mm.

- 2000W laser welder machine: the welding effect is good for plates with a thickness of less than 8mm.

Application of Laser Welding Machine

- Stainless steel

- Carbon steel

- Various plates

- Mold

- Cabinets

- Water tank

- Kitchen and bathroom products

- All kinds of hardware lighting

- Advertising signs

- Window frames and door panels

The most important thing about handheld laser welding machines is the continuous updating and adjustment of technology.

Almost “zero” after-sales service can be achieved.

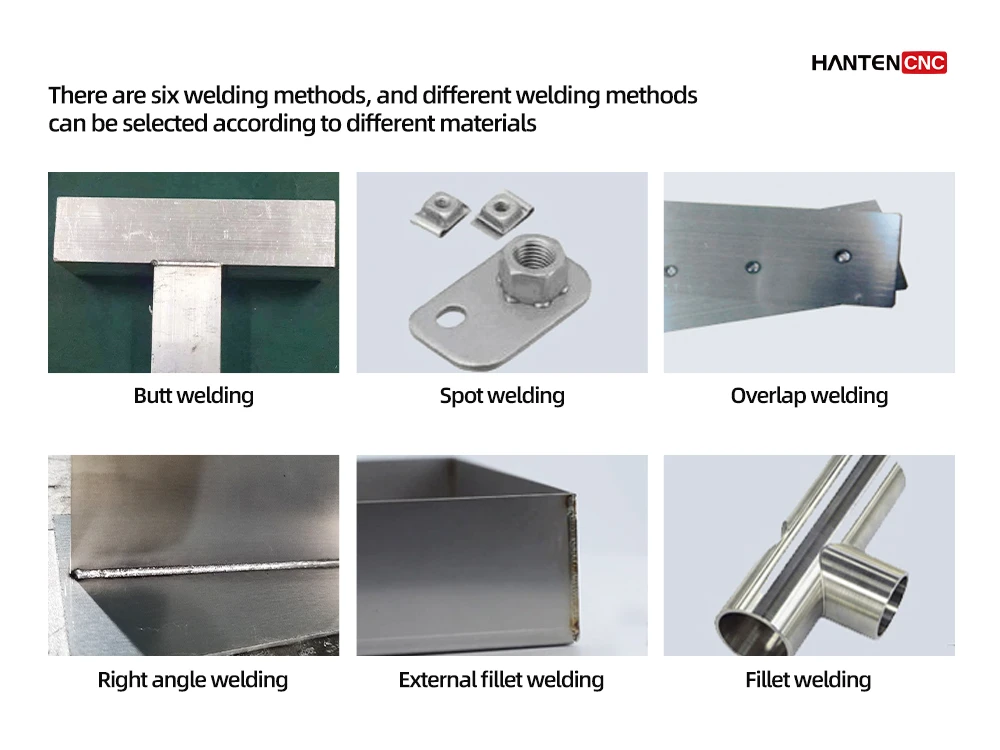

Laser Welding Method

- Tailor welding

- Stitch welding

- Internal and external fillet welding

- Arc welding

- Special-shaped welding

Hand Held Laser Welding Effect

- It has small weld width, small heat-affected zone, small deformation, and fast welding speed.

- The weld seam is flat and beautiful. After welding, there is no need for treatment or a simple process.

- The weld seam is of high quality and free from porosity. This reduces and optimizes base metal impurities.

Finally, you can choose suitable welding equipment according to your own needs. If you need laser welding equipment, you can contact Hanteng CNC for the first time. We will provide you with satisfactory service.

Environmentally friendly

In recent years, countries worldwide have had higher and higher requirements for environmental protection.

Argon arc welding will produce a large amount of welding dust and slag. It is extremely harmful to the environment. Companies that fail to meet environmental protection requirements will face regulatory oversight. And laser hand-held welding is relatively less harmful to the environment. It can be widely used in some irregular and complicated industries.

For example cabinets, kitchens and bathrooms, stair lifts, shelves, ovens, stainless steel doors, window guardrails, distribution boxes, stainless steel home furnishing, and other industries.

Handheld Laser Welder Applicable Working Conditions

The price of handheld laser welding machines is tens of thousands.

Many customers who intend to introduce a handheld laser welding machine have concerns about its use and performance. Some customers have used it for some time and summarized the following content. The handheld laser welding machine is suitable for the following working conditions:

- Large welding area requires high welding efficiency.

- The thickness of the plate is above 0.5mm.

- Solve the problem of weld beauty and deformation.

- Mainly made of stainless steel, iron plate, and aluminum.

- There is a certain amount of budget space.

- To solve the labor problem, the handheld laser welder can start working with zero welding foundations.

It is good to use laser welding for the above working conditions. However, there are many precautions in the standard operation during use. You must pay attention, otherwise, the cost of use will be very high.

If it is precision product welding and welding of very thin materials, hand-held laser welding equipment is not suitable. Also, hand-held laser welding cannot weld copper.

Choose Us

When the quality is guaranteed, a hand held laser welding machine that can meet your needs is considered good. It is best to directly choose the manufacturer of laser machines. Generally, regular large factories produce in strict accordance with regulations. The factory’s after-sales service is more guaranteed, such as HANTENCNC.

To sum up, Hanteng still recommends that you use a laser welding equipment, which is a huge profit. If you need to consult, we will answer your questions about laser welding machines one-on-one.

Please leave a message for discussion if you have any questions.