Laser marking is the best and fastest way to make marks on things. It doesn’t even touch the object. Unlike other methods, laser marking is much more reliable and safe. This “UV laser VS Fiber Laser Marking Machine” guides you in learning more about UV and fiber lasers.

This article mainly discusses the similarities and differences between each method. If you know how they differ, you can choose the correct method for your project.

UV Laser VS Fiber Laser Marking Machine: Similarities

All laser marking machines serve the same purpose: marking things. UV and fiber laser marking machines are both prevalent in a wide range of applications. People use them to mark metals, plastics, wood, and more. Although they have some differences, they share some similar properties.

UV Laser vs Fiber Laser Marking Machine: Precision and Accuracy

Both UV and fiber laser marking machines are highly accurate. They both use highly focused laser beams to create great-quality markings on materials. The final result is always fine and detailed.

UV and fiber laser marking machines can be used multiple times. They prove high repeatability in all-purpose marking jobs. In general, both laser devices work on most solid materials. Fiber lasers may have some difficulties dealing with organic materials.

Both fiber and UV laser marking machines are non-contact processes. Therefore, marking with these machines ensures the integrity of the material surface. This means that both laser sources produce less HAZ area near markings.

Fiber Laser VS UV Laser Marking Machine: Non-contact Process

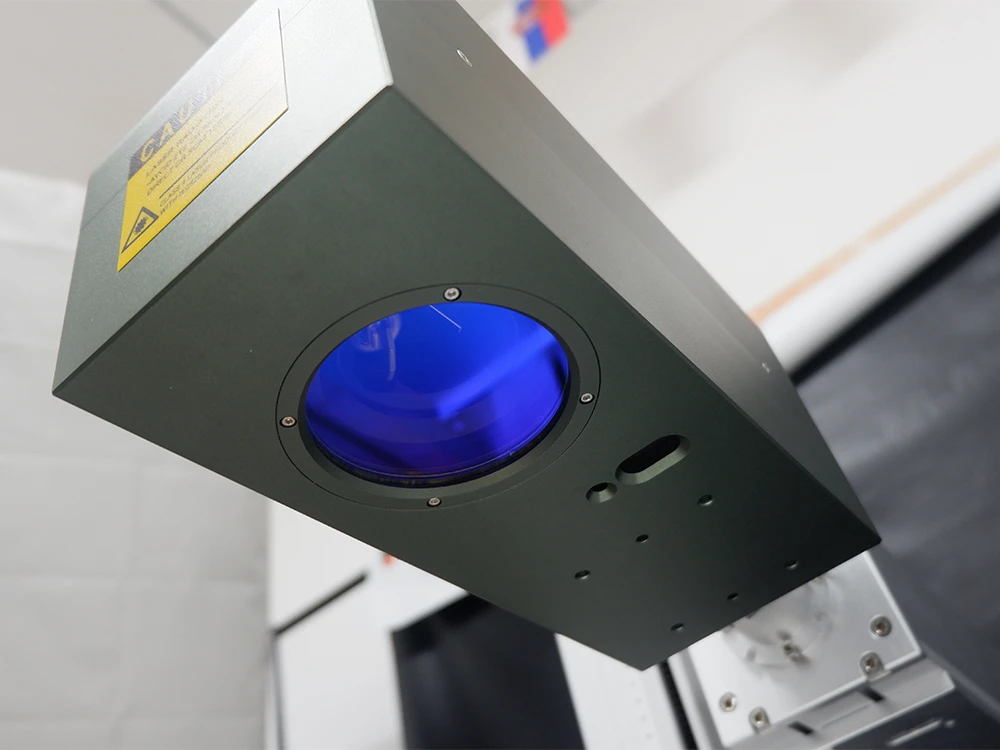

Both fiber and UV laser markers use a laser gun during the marking process. The laser sources finally send out a focused laser beam that hits the objects through this laser gun. When the laser hits the object, the temperature goes up very quickly. This rapid situation generally melts and vaporizes the material from its surface. Finally, what you see is permanent high-contrast laser marking. This whole process is non-contact.

Once the process is done, there is no need to touch the material. You don’t even need surface finishing. However, some non-metal or organic materials may need surface finishing right after the laser marking.

UV Laser vs Fiber Laser Marking Machine: Permanent Markings

UV and fiber lasers produce permanent markings on objects that cannot be easily erased. Unlike paintings or stickers, laser marking lasts longer as the product lives. Since they produce long-lasting marks, most industries prefer them to label their products.

There are various laser markings, with six significant types in general. Laser ablation, foaming, and annealing are some of the popular methods. Whatever the process, all laser markings are permanent. However, the contrast and depth of engraving may vary based on materials and laser settings.

Fiber Laser VS UV Laser Marking Machine: Low Maintenance

Fiber and UV laser marking machines need low maintenance. Both are designed to last longer and usually do not need consumables. Fiber lasers can reach a lifetime of up to 100,000 hours, while UV lasers may have up to 20,000 hours. During this time, they both need very minimal upkeep work.

You may have to clean the lenses and check the cooling systems. Also, every time you laser mark objects, you must calibrate the height and focus of the laser machines.

Most modern laser marking machines have advanced laser technology. Both fiber and UV laser marking machines, have efficient cooling systems. Therefore, your laser machine does not often overheat, which helps extend its lifespan.

UV Laser vs Fiber Laser Marking Machine: Eco-friendly Technology

Both UV and fiber laser marking machines do not need consumables. They also do not produce fumes or harmful gases when laser marking. Therefore, these laser markers are cost-effective and eco-friendly.

Also, UV and fiber lasers operate without physical contact. Therefore, there is no chance of errors while marking materials.

The whole laser marking process is done in a controlled setting. It doesn’t produce sparks or does not accidentally create fire in nearby dry things. Therefore, both fiber and UV laser marking machines prove to be very eco-friendly technology.

Fiber Laser VS UV Laser Marking Machine: User-friendly Design

Fiber and UV laser marking machines both have user-friendly systems. They are easy to use and simple to set up. Even though some machines have attached monitors, they all have simple operating systems.

They are usually touchscreen. For instance, modern CNC laser marking machines come with a user-friendly display. The machine can be operated in over 20 languages, making it very easy. Even a simple understanding of lasers can do this job.

UV Laser VS Fiber Laser Marking Machine: Dissimilarities

You already know how UV and fiber laser markers are the same in a few ways. However, they still have some differences, which matters most in the real world. Due to these differences, they are usually better suited for different jobs.

UV Laser vs Fiber Laser Marking Machine: Wavelength

UV and fiber lasers have significantly different wavelengths. A laser’s wavelength plays a crucial role in marking diverse materials.

The wavelength of most UV lasers is short, between 150 and 350 nm. It ranges from 780 nm to 2280 nm for fiber lasers but not for other types of lasers. The laser wavelength difference significantly affects materials’ energy absorption. For instance, metals usually require a laser wavelength from 1064 to 1070nm. Note that more or less than this value will not work, not metals, unless the metal parts have the coatings.

Moreover, shorter wavelength lasers are generally ideal for marking heat-sensitive equipment. Because of this, UV lasers are often used on glass, plastic, and some metals. On the other hand, fiber lasers are suitable for materials with high energy density.

Fiber Laser VS UV Laser Marking Machine: Material Compatibility

The laser wavelength typically determines which material you can work with which laser. Fiber and UV laser marking machines are both versatile in this case. They both produce permanent marks on various materials. However, there are usually some differences between them.

As you know, UV laser produces shorter wavelengths. Therefore, they usually make less heat. Because of this, people prefer this machine for heat-sensitive products. Working with plastics or glass needs a very careful step. UV laser markers, in this case, help a lot.

Fiber laser, on the other hand, produces a higher laser wavelength than UV. Their laser wavelength is highly suitable for working with metals. Therefore, fiber laser markers are often used in the metal industry.

UV Laser vs Fiber Laser Marking Machine: Heat Generation

Regarding heat generation, the laser wavelength matters a lot here. As you know, UV lasers usually operate at 150 to 350 nm wavelengths. UV laser marking is called the cold marking process compared to other laser marking methods. This means they produce less heat and reduce the risk of your material damage. Therefore, UV laser marking machines are highly suitable for heat-sensitive materials.

Fiber laser marking tools, on the other hand, make longer wavelengths. Because of this, they make more heat during writing than UV lasers. Because of this, heat-affected zones (HAZ) could form on objects, especially metals. Fiber laser markers work best on hard materials.

Fiber Laser VS UV Laser Marking Machine: Marking Speed

Once again, the laser wavelength also matters when considering the marking speed. Fiber laser marking uses longer wavelengths. It offers faster marking speeds on metals and plastics. It usually produces high-intensity light that can quickly engrave or mark surfaces. One single pass is generally enough to create high-contrast markings.

On the other hand, UV lasers have a shorter wavelength. They produce finer markings, but the process is slower than fiber laser markers. You may need multiple passes to get the high-contrast results.

UV Laser vs Fiber Laser Marking Machine: Cost

UV laser markers are generally more expensive than fiber lasers. As you know, UV lasers are more greener than fiber lasers. They produce less heat and are considered cold laser markers. Engineers must use complex setups to achieve such properties, which adds extra costs.

On the other hand, fiber lasers are more cost-effective. They use longer wavelengths and are great for marking metals and plastic. Fiber lasers are widely used in industrial settings and many DIY projects, making them an excellent choice for beginners.

Fiber Laser VS UV Laser Marking Machine: Application Across Industries

Considering the above few factors, you can now guess the application of each laser type. Fiber lasers are more powerful. They work well with metals like SS, Al, or Copper. Therefore, you can find its applications in the auto, aerospace, and electronics industries. Note that fiber laser’s high energy typically allows you to do deep engraving.

UV lasers, on the other hand, are gentler. They are great for marking delicate components and ideal for heat-sensitive products. The packaging, medical, and cosmetics industries significantly use this device. It produces less heat and reduces the risk of material distortion.

Summary

Fiber and UV laser markers both have some good points in common. They are accurate, can be used on many materials, and are environmentally suitable. They are also easy to use and don’t need as much maintenance. But they are also different in some ways. The most crucial difference between them is their wavelength. UV lasers make shorter wavelengths, while fiber lasers make longer wavelengths.

UV lasers don’t produce much heat but take time to finish. In contrast, fiber lasers are powerful, quick, and cheap but form HAZ on metals (if not handled carefully). Each has pros and cons, meaning they can be used for different things.

For more information about UV and fiber laser markers, visit our machines page. You can also leave a question or request an instant quote for a device. Our customer support team is always ready to answer your queries.