This HantengCNC ultraviolet laser marking machine is efficient and flexible. The ultraviolet laser uses a high-energy beam to remove surface material without contact precisely. Therefore, the UV laser marking machine can achieve finer, higher-contrast marking effects, and the marking effects are firm and permanent.

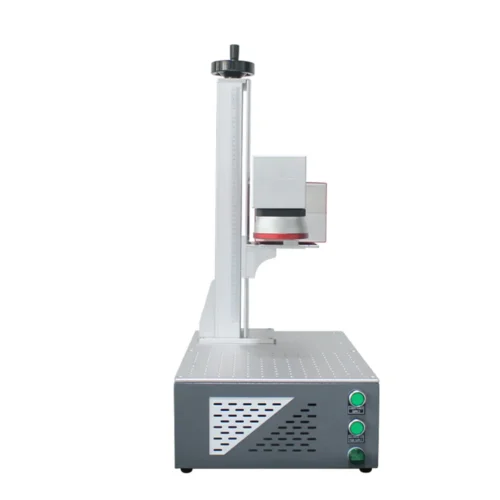

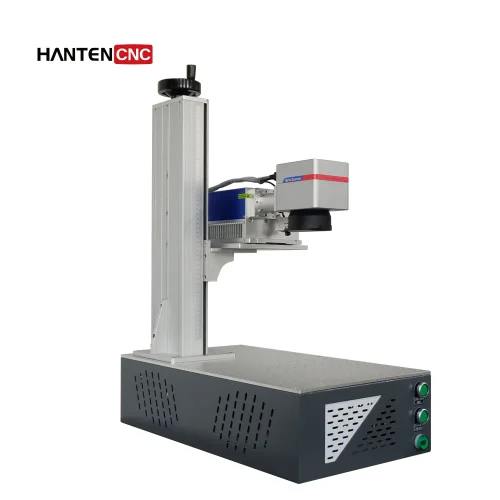

Our ultraviolet laser marking machine adopts an integrated design with a thin, compact, and flexible body. It has a built-in high-speed laser marking motion system and control software. The “cold processing” marking method prevents scratches and damage to the material. The beam quality is higher, and the focused spot is smaller, which can achieve super-precise marking effects.

Components of UV Laser Marking Machine

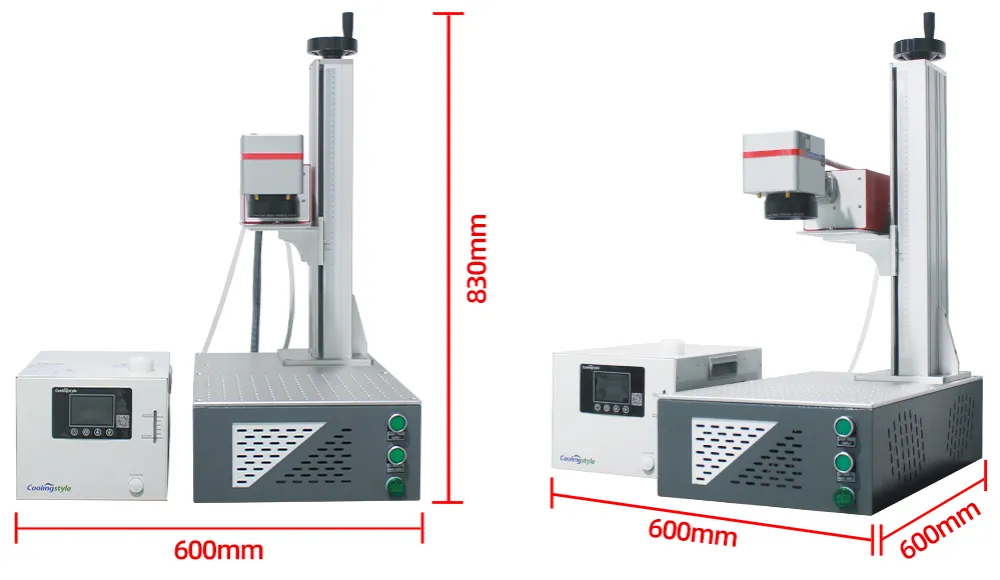

Dimensions of UV Laser Marking Machine

UV Laser Marking Machine Parameters

| Model | HTU-3 | HTU-5 | HTU-10 |

| Power | 3W | 5W | 10W |

| Laser source | JPT | JPT | JPT |

| Central wavelength | 355nm | 355nm | 355nm |

| Frequency range | 20 kHz-150 kHz | 20 kHz-150 kHz | 40 kHz-300 kHz |

| Marking area | 100mm-200mm | 100mm-200mm | 100mm-200mm |

| Beam quality | M²≤1.2 | M²≤1.2 | M²≤1.2 |

| Beam diameter | 0.55±0.15mm | 0.55±0.15mm | 0.45±0.15mm |

| Supply voltage | DC 12V | DC 12V | DC 36V |

| Cooling method | Water-cooled | Water-cooled | Water-cooled |

| Galvo head | RC1001 | RC1001 | RC1001 |

| Machine net weight | 58.8kg | 58.8kg | 58.8kg |

| Machine dimension | 800*670*660mm | 800*670*660mm | 800*670*660mm |

Details of UV Laser Marking Machine

Our UV laser marking machine is equipped with JPT laser source, RC1001 galvanometer, and Coolingstyle water cooler. The three major components work together to improve the speed, accuracy, stability and reliability of the laser marking system.

RC1001 Galvanometer

This galvanometer uses a high-speed motor imported from the United States, which is small in size, fast in speed and high in accuracy. The performance of the galvanometer system is very stable and reliable.

The differential photoelectric sensor accurately detects the motor position with good linearity, minimal drift, and high resolution for repeat positioning accuracy.

UV Laser Source

Hanteng CNC uses JPT UV laser. This ultraviolet laser has excellent beam quality (M2≤1.2) and near-perfect spot characteristics (spot roundness ≥90%). The UV laser adopts an optoelectronic integrated structure design; that is, the optical path and the drive circuit are integrated, so it enhances interference resistance. The fully sealed structure is dust- and moisture-resistant, making it suitable for harsh industrial environments.

Equipped with an internal cavity self-cleaning function. By keeping the interior of the laser clean, it reduces the wear on optical components, thereby extending the laser’s lifespan.

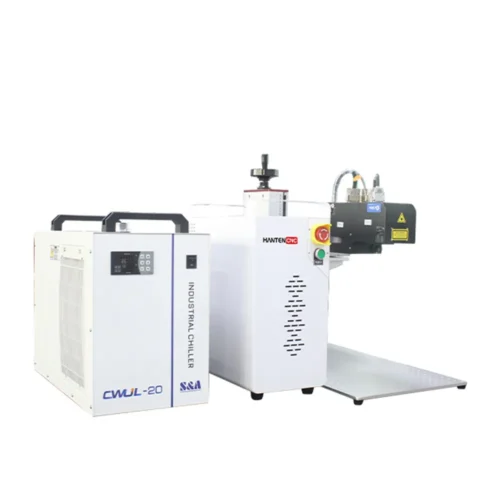

Cooling system

The laser UV marking machine uses Coolingstyle water cooling system with precise temperature control of ±0.1℃. It is small in size, light in weight and low in energy consumption. It can quickly absorb and discharge heat, thus providing stable temperature control.

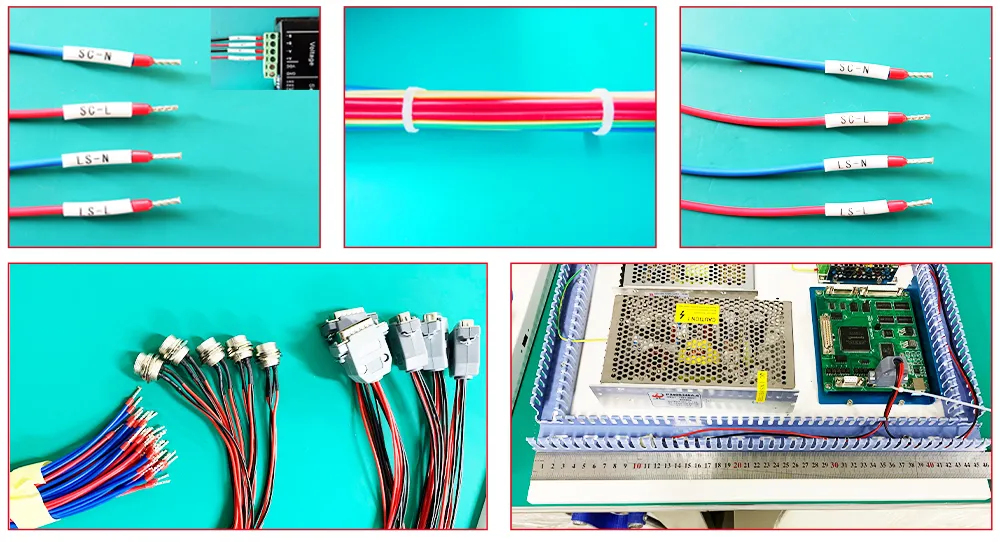

Well-organized Internal Wiring

The wiring layout and clear markings of the laser UV marking machine enable you to quickly identify and locate various components and their connecting cables. Prevent equipment damage or functional failure caused by improper wiring during initial installation or component replacement.

Laser UV Marking Machine Sample Display

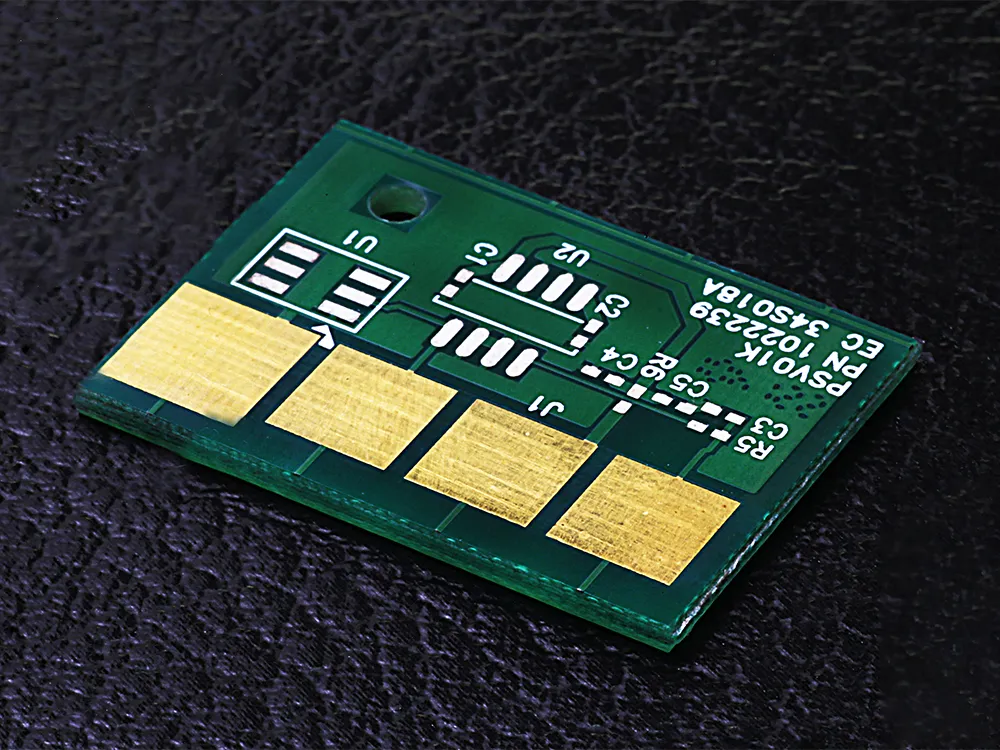

UV Galvo laser marking machine can be used on various materials, including plastics, glass, ceramics, silicon wafers, and organic materials. Its high precision and low thermal impact make it particularly suitable for applications that require high-precision labeling on heat sensitive materials, such as electronic components, medical devices, jewelry, food packaging, and integrated circuits.

Application area and advantages:

1. Food industry: Our UV Galvo laser marking machine will not penetrate the outer packaging during the marking process and will not cause air leakage.

2. Pharmaceutical industry: Laser UV maker will not damage the outer packaging and have visual reading and anti-counterfeiting functions.

3. Hygiene industry: Our laser UV marking machine uses a cold light source for coding, which will not cause dust explosions.

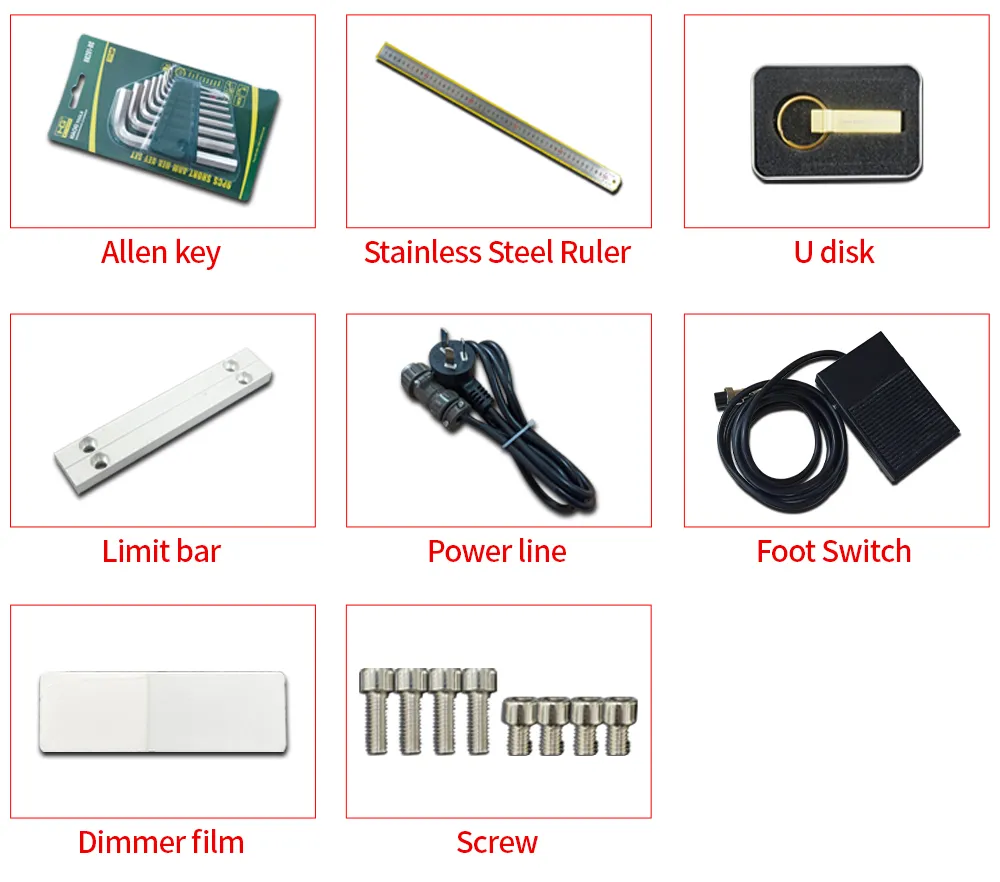

Included Accessories of Laser UV Marking Machine

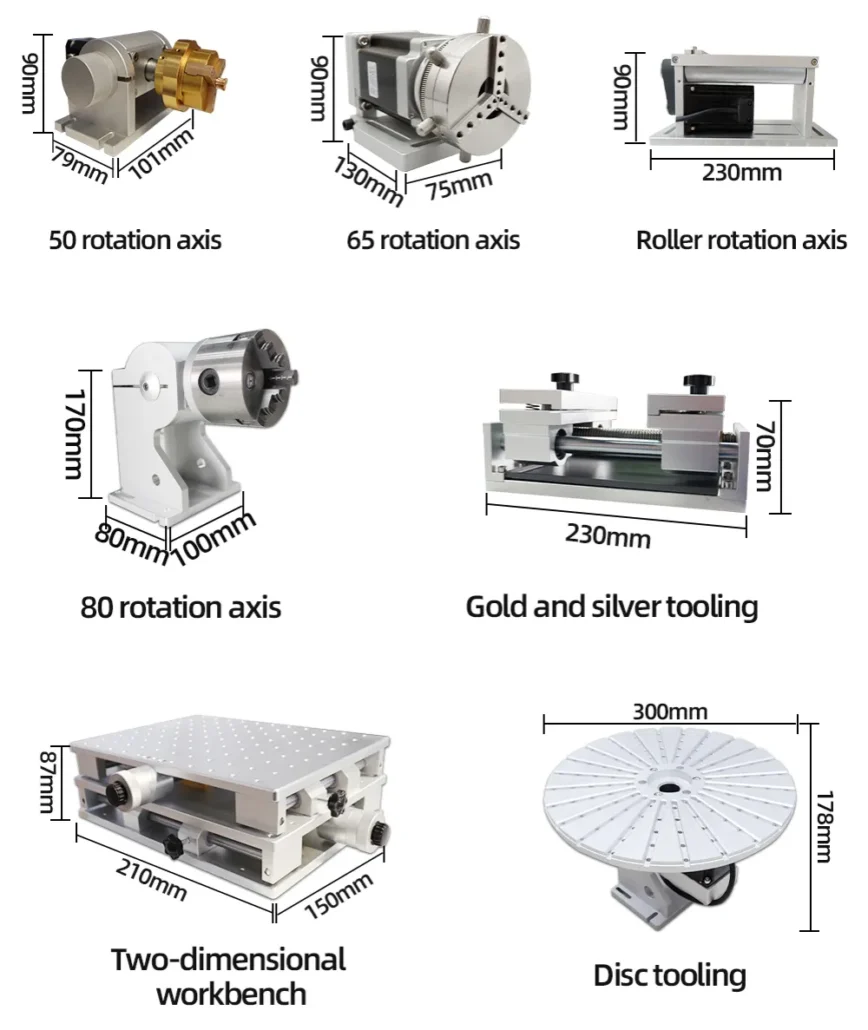

Laser UV Marking Machine Accessory Selection

Customer Reviews

Customer Visits

Qualification Certifications

HANTENCNC Partnerships