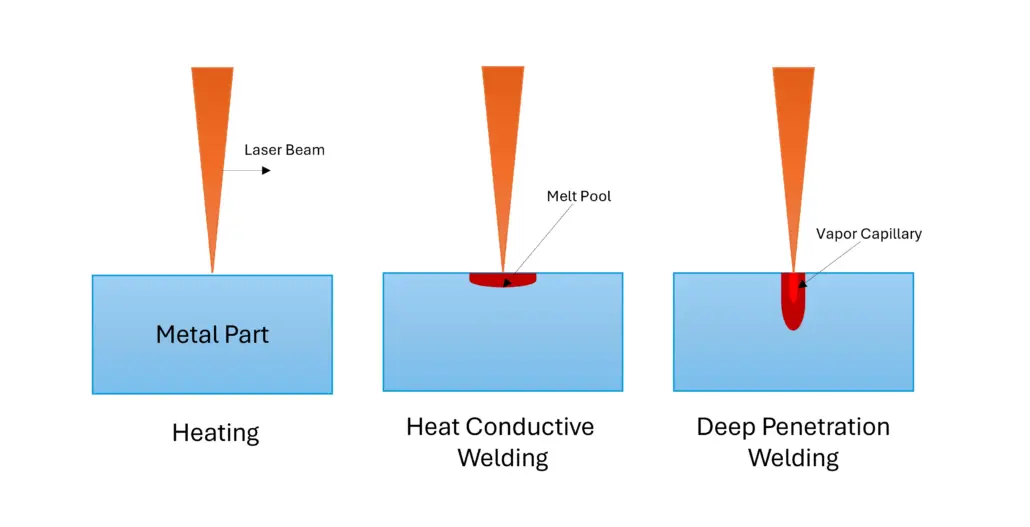

Laser welding is a fantastic way to join different metal parts. As usual, the method uses high-power laser beams to melt metals and then uses the molten metal to weld the separate parts. The joining technique may vary based on different material types. Deep penetration laser welding is one of the most popular techniques. And it is mostly used for thicker metals.

Another method used is heat conduction welding. This technique can create penetration depths of up to 1-2 mm and is widely prevalent for welding thinner metals.

Both of these techniques may use pulsed or continuous lasers. Also, they may come with CO2 lasers or fiber lasers. The exact type typically depends on various factors. However, fiber lasers are the most popular here.

Both heat conduction welding and deep penetration welding have unique pros and cons. You can choose the right type for your project by comparing these pros and cons. This way, you can ensure a better and more reliable welding result.

The suitability also changes when considering the difference between pulsed and continuous lasers. The pulsed laser provides an interrupted laser beam, but the continuous laser does not. A pulsed laser is ideal for working with thin metals. This laser source also produces less distortion and HAZ. You will find its use in heat-conductive laser welding.

A CW laser is exclusively suitable for thick metal welding. You can not use it on soft or thin metal parts because it will create distortion and a large HAZ. This type of laser is also used in deep-penetration welding.

This article is all about the deep-penetration laser welding method. How does this welding work, and what are its benefits?

What is Deep Penetration laser Welding?

DPLW, or Deep Penetration Laser Welding, produces a deep, narrow weld. This deep penetration structure resembles a keyhole, hence the name “keyhole laser welding.”

DPLW laser welding uses a highly focused laser beam, mostly continuous lasers. It penetrates deeply into the material to form a keyhole.

A keyhole is a small cavity that extends deep into the workpiece. This keyhole creates a greater weld depth during laser welding than other methods.

Another popular method is heat conduction welding. This method produces low output power and doesn’t produce a keyhole. It only relies on surface melting. Thus, it can only deal with 1-2 mm thin metal parts. Compared to this method, keyhole laser welding creates strong and precise welds.

Befits of Deep Penetration Laser Welding

Deep penetration laser welding is suitable for many reasons. Its benefits typically make this process effective in many industries. Let’s check them out.

(1) The most crucial benefit of DPLW is deep weld penetration. A high-power weld machine can create a deep hole in a single pass. This feature is especially suitable for thick metals.

(2) This method produces a very strong weld. It often offers the strength of the base metal itself.

(3) Since this welding method uses laser beams, it must be accurate. Because of this, you can reduce errors and defects in welding.

(4) Since DPLW creates keyholes rather than melting the surface, it makes less HAZ. As you know, HAZ is the main reason for warping.

(5) As usual, laser welding is a versatile process. You can weld on all types of metals. However, you must be careful when dealing with deep penetration welding. This method is suitable for thicker metals. For thin metals, you had better choose heat-conductive welding.

(6) Deep penetration laser welding eliminates many post-welding operations and treatments.

(7) This welding method can be easily integrated with an automated system.

How Does Deep Penetration Laser Welding Work?

Deep penetration laser welding means making a hole called a keyhole. The molten metal created in this process typically joins separate parts. Sometimes, the bond strength becomes almost the same as that of the base metal.

To explain it, let us take an example based on a real-life situation. Suppose you want to join two metal plates using the deep penetration method. Well, then, to begin with, let’s gather the materials that are needed to start the process.

First, clean the metal parts thoroughly so the contaminants can not interfere with the weld quality. Then, choose an appropriate flat surface to hold these pieces together. Ensure as little gap as possible between them.

Second, get your laser welding machine ready for the work. You must adjust the laser settings depending on the type of surface at which you are directing the laser. You should stick to the recommended settings as much as possible. However, the actual process starts when you switch on the laser machine.

When a laser strikes the metal surface, the temperature of the metal surface goes up to the melting point immediately. This melts the metal there and creates a “keyhole.” However, as the molten metal cools, a robust bond forms between the two pieces.

In this manner, the laser gun gradually slides across the joints of the metal parts to form a good weld.

Application of Deep Penetration Laser Welding

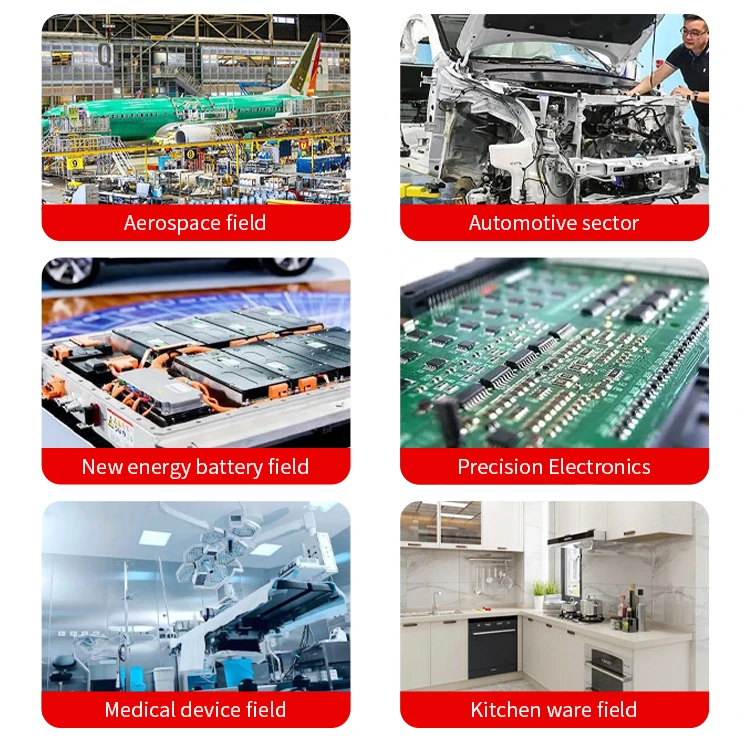

Deep penetration laser welding is mainly used to make strong joints. This method is used in many applications worldwide.

What type of metal are you working with? How about the thickness? What will this joint be used for? Based on these questions, the correct laser welding method is chosen. As you know, keyhole laser welding uses high-power devices, which are very expensive. Even high-power laser devices are not suitable for lower-power welding jobs. So, you must be careful when choosing an ideal laser welding method.

Let’s get back to the use of deep-penetration laser welding. As said, it is widely popular in many industries. The auto industry counts on it to make a lot of structural parts. Car parts like fuel injectors, gearboxes, and engine parts are all common examples. In the marine and aerospace sectors, you might find similar uses.

The medical and electronics sectors also extensively use deep-penetration laser welding. In this field, precision is the most crucial need. This method is also prevalent in machine manufacturing, where it is used to create many machine parts.

This method is also used to create molds in casting foundries. Casting parts also undergo this process to make the final parts.

Factors that Affect Deep Penetration Laser Welding

Deep penetration laser welding is a critical process. Several factors directly affect the overall quality of its outcome. You might see some welding defects if these factors are not handled carefully. For instance, incomplete penetration, poor weld quality, and spatter are typical.

The Density of the Laser Beam

Laser beam density is generally the concentration of laser energy. It is calculated per unit area and mainly depends on the spot diameter of the laser beam. The density also heavily relies on the type of laser beam. The top-hat beam generally produces a consistent beam density.

The laser beam density typically plays a crucial role in deep penetration. A high-density laser beam creates a more effective keyhole. Inaccurate or inconsistent beams may create blowouts and porosity.

Welding Speed

Laser welding is directly influenced by welding speed. Slower speeds create deeper penetration. However, extremely slow speeds may cause overheating and more HAZ. The main reasons for metal parts warping are HAZ and overheating.

Higher speed, on the other hand, reduces the penetration depth. High-speed laser welding may create incomplete fusion. Therefore, always stick to the recommended laser settings.

Focus Position

The focus position is the critical point. It is the position in which the power of the laser beam is most focused. You must adjust the focus point when working with a laser welding machine. However, most modern laser welders come with a fine-tuned nozzle. In this case, always consult a professional.

The laser beam density diminishes if the focus position is above or below the surface. Some defects associated with this factor may be undercut, lack of fusion, or excessive spatter.

Protective Gas

Protective gas is typically used in laser welding to prevent contamination. The molten metal may easily get oxidized or contaminated during welding, which may interfere with laser welding. In this case, controlling this assist gas also affects the outcome of DPLW.

Argon, helium, and nitrogen are widely used protective gases for laser welding. However, some modern laser welders typically don’t need protective gases.

Workpiece Joint Clearance

Joint clearance is typically the gap between the workpieces being welded. Try to keep this gap as small as possible when using laser welding. It directly affects deep-penetration laser welding.

Proper joint preparation always helps achieve the best outcome. Not taking it seriously may create an incomplete weld pool.

Material Type

The final factor, material type, is the most critical. For deep penetration laser welding, you must choose thicker metals. Once again, reflective materials need more powerful laser density.

You might find more HAZ, warping, cracking, or porosity if you choose an incompatible material. Note that every material has unique melting points and cooling rates.

Summary

Deep penetration laser welding is a trendy method used in many sectors. In short, it creates strong and accurate welds. Sometimes, experts claim that the strength achieved through the process is almost the same as that of the base metal.

The keyhole welding technique offers several benefits.

(1) First, this technique provides the most robust solution. (2) This technique does not need any consumables, so it is eco-friendly. (3) This method typically eliminates the need for post-welding work.

Hanten CNC specializes in manufacturing various types of laser welding machines. If you are interested in it, you can navigate to our product pages. For more information, contact us.