The laser source is the heart of laser machines. It produces the laser beams and controls its power output, just like your heart in your body. JPT and Raycus laser sources are two popular brands nowadays. Both are good for laser operations. Nevertheless, these two brands have some suitability issues that need to be found. The article “Raycus vs JPT Laser Source: Which is Better?” compares them and helps readers find the best option for their project.

People often ask, “Is JPT better than Raycus?” This article will use a few points to help you find the best option.

What is Raycus Laser Source?

Wuhan Raycus is a leading fiber laser technology manufacturer worldwide. Established in 2007, Raycus has developed its production line, producing many laser sources today.

Ray laser sources come in many types: CW, QCW, Pulsed, Q-switched, MOPA, direct diode, ABP, and 3D printing lasers. This factory offers all kinds of laser sources.

(a) CW Raycus fiber laser source creates a continuous laser waver. This means this laser source produces uninterrupted laser beams. Raycus fiber laser source is suitable for laser cutting and welding.

(b) QCW means Quasi Continuous Wave. This Raycus laser operates in a continuous and pulsed mode. You can choose any mode you want. Therefore, the QCW Raycus fiber laser source suits high-peak and low-peak power jobs.

(c) Pulse fiber laser source, on the other hand, only provides pulse lasers. They are perfect for marking, welding, engraving, and micro-machining.

(d) Q-switched lasers store energy and release it quickly. In this way, high-intensity laser pulses are produced. These laser sources are also good for laser engraving and cutting.

(e) MOPA laser offers more control on laser beams. These laser devices offer flexible pulse duration and frequency. Although MOPA lasers are expensive, they are perfect for fine-marking large and small parts.

(f) ABP means adjustable beam profile. This means you can shape and size the laser beam. By doing so, ABP Raycus laser sources are perfect for intricate cutting, drilling, and material processing.

Pros

- You have many options here. The Raycus factory offers all popular types of laser sources, and you can even order custom specs.

- Cheaper than other brands

- Raycus laser sources can produce very high peak power, which is necessary for deep cutting and makes them ideal for cutting metals.

- These laser sources come with a robust construction and guarantee long-lasting services.

Cons

- The range of laser frequency is also relatively low.

- This laser source may not be suitable for plastic engraving.

What is JPT Laser Source?

JPT laser sources are the primary products of Shenzhen JPT Opto-electronics Company Limited, an international brand registered in 2006. People prefer JPT laser sources for their precision and reliability. There are three main types: MOPA fiber, CW, and DPSS lasers.

(1) MOPA stands for Master Oscillator Power Amplifier. This JPT laser source offers excellent control of pulse durations and frequencies. This feature gives you more precision and control. You can use a JPT MOPA fiber laser to engrave and mark metals and plastics.

(2) CW or continuous wave, JPT fiber laser produces an uninterrupted laser beam. This type of laser is ideal for laser cutting, welding, and drilling. People prefer JPT CW fiber lasers because they are stable and efficient.

(3) DPSS stands for Diode Pumped Solid State Laser Source. This JPT laser source uses a diode to pump a solid crystal, making laser beams. These JPT lasers are suitable for micromachining, marking, and engraving delicate parts.

People prefer JPT laser sources for many uses. The car industry uses JPT lasers to engrave various parts and mark serial numbers. The electronics industry uses JPT laser sources to cut and shape most components. Similar uses can also be seen in medical, jewelry, and other factories.

Pros

- JPT laser source offers improved laser beam quality. CW JPT laser gives consistent results and precision. Therefore, you can get accurate and detailed results from laser engraving, cutting, and marking.

- These fiber laser sources are stable. Also, they give consistent output even if you use it frequently. Because of this, you use these laser sources for a long time. This reliability is typically crucial for businesses that need long production runs.

- JPT laser source is highly efficient. Less Power Consumptions. You can enjoy optimal energy use and save costs for your businesses.

- You can use a JPT laser source on various materials. You can create awesome projects using the CW laser, like signage, photo frames, electronic cases, etc.

Cons

- JPT laser sources are relatively costlier than Raycus Laser sources.

- This brand doesn’t offer custom solutions for their customers. You must choose the standard specifications for your laser device.

Raycus VS JPT Laser Source: Which is Better?

You are now already familiar with Raycus and JPT laser sources. Also, you learned their pros and cons. This section will find out which brand might be better for your project.

Raycus and JPT create accurate and consistent results, but they still differ. These differences typically make them suitable for different applications.

To compare, we will use five primary points: result, frequency, stability, compatibility, and cost. These five factors determine whether the laser source is ideal for your project. You will mainly know the strengths and weaknesses of each brand.

Raycus VS JPT Laser Source: Laser Outcome and Efficiency

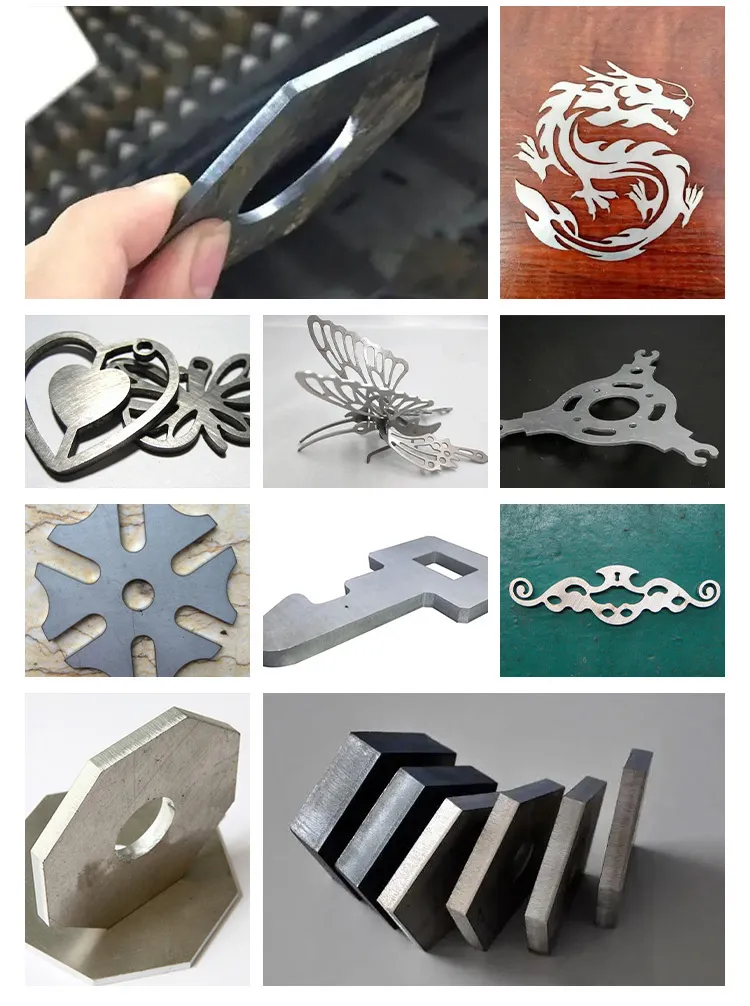

Raycus fiber lasers can reach high peak power. Undoubtedly, you can get consistent results every time. Because of the high peak power, you can create deep cuts into various materials. You can work on any material, such as metals, wood, acrylic, and leather. However, you struggle to work with plastics.

JPT laser sources offer better beam quality, consistent results, and high-quality cuts. According to various customer reviews, JPT laser sources create less HAZ than Raycus.

Which is better? Raycus is cheap and requires fewer consumables. If you do not need high-quality cuts, especially for delicate parts, Raycus can be the better option. However, if you need a high-quality cut, whatever the type of material, JPT laser source is the best option.

Raycus VS JPT Laser Source: Laser Frequency

Raycus fiber lasers are reliable. There’s no doubt. It is also effective for many typical applications. However, the Raycus laser may offer fewer frequency ranges than the JPT laser. Because of this, your outcome might be limited to some quality levels.

In contrast, the JPT fiber laser offers more frequency ranges so that you can create more precise results. JPT fiber lasers are suitable for quality engravings. For custom products, these laser sources are the best option.

Raycus VS JPT Laser Source: Stability

Stability in laser engraving is a very critical parameter. This factor mainly determines the laser engraving output in high-volume orders. Can your laser device work continuously? Can it output the same results?

Both Raycus and JPT laser sources are stable devices. They have robust designs and can deliver stable performance. According to customer reviews, JPT laser sources offer more stability than Raycus fiber laser. However, the techniques of using laser sources depend on your expertise. If you are a beginner, it is better to choose JPT laser sources.

Raycus VS JPT Fiber Laser: Material Compatibility

Raycus fiber laser source can cut, engrave, or mark any solid material. It is especially suitable for metals because it can produce high peak power. However, working with plastics using this laser device may be challenging.

The JPT laser source, on the other hand, offers more excellent compatibility. Its superior beam quality allows you to engrave almost any material. The JPT MOPA fiber laser is the most widely used option.

Which is better? The Raycus laser source is better if your primary focus is metalwork. However, the JPT laser gives the best result for versatile works.

Raycus VS JPT Laser Source: Cost

The final factor is the budget. How much do you budget for your laser device? What are your future works? Will you only focus on metalwork? Will you work on small and delicate parts?

Well, a Raycus laser source is generally cheaper than a JPT one. Therefore, it is the best option for those with a tight budget.

However, consider the above four factors when deciding on the best option. Combining all these factors and assessing each brand’s strengths and weaknesses, you can finally make the right choice for your project.

Summary

In this “JPT Laser vs Raycus” comparative article, you have got many useful information about these two brands. Both brands are good. People use them in many laser operations. However, they still have some differences. To find the best option, you must assess their suitability.

The strength of the Raycus laser source is its robust construction and stability. It can also produce high peak power. Most importantly, it is a cost-effective solution. On the other hand, the strength of the JPT laser source is its superior beam quality and effectiveness. Although JPT is more expensive, it offers the best quality engraving.

Which is better? Now, assess these strengths and weaknesses and judge whether they suit your project needs. The following table summarizes the differences between them.

| Factor | Raycus Laser Source | JPT Laser Source |

| Power and Efficiency | High peak power, efficient for cutting and welding | Versatile and accurate control, especially MOPA laser source |

| Availability | Wide range of laser sources | Limited range of laser sources |

| Laser Frequency | Fixed pulse duration so that you may struggle with accuracy | Adjustable pulse durations with MOPA technology |

| Beam Quality | Relatively low beam quality | Superior beam quality |

| Material Compatibility | You may struggle to work with plastic material | Versatile, you can work with all types of solid materials |

| Stability | Robust and stable | Robust and stable |

| Cost | Cheap | Expensive |

| Engraving Results | Fair quality engraving | Good quality Engraving |

| Warranty | 1 year | 1 year |