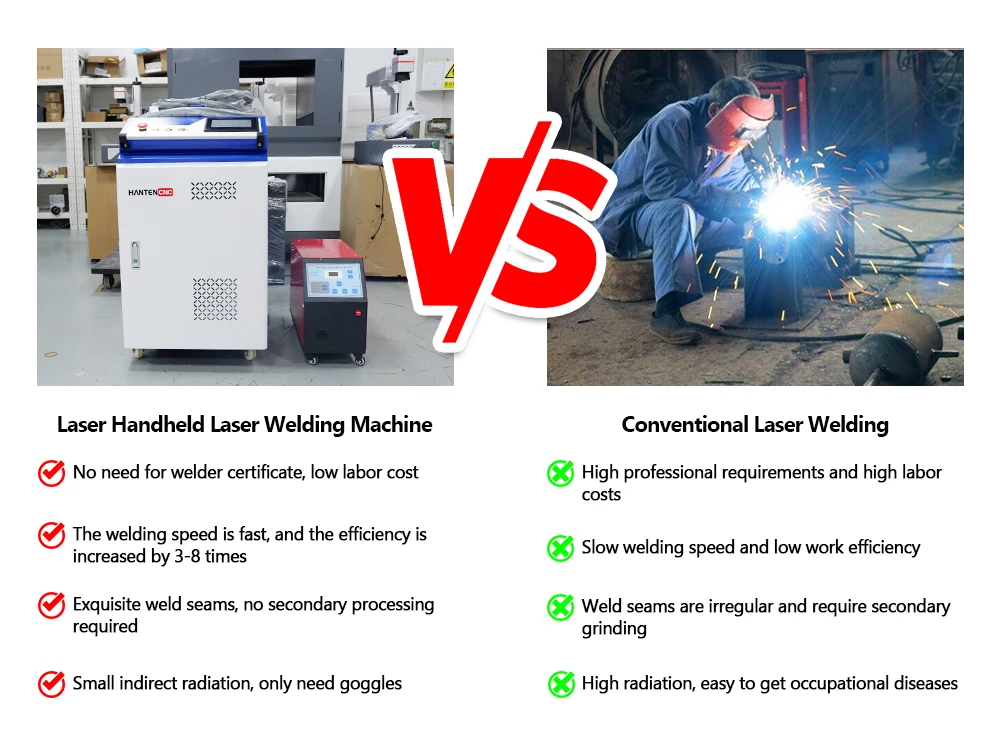

Advantages of laser welding machine compared with tradition

With the development of the times. Laser welding machine has replaced the traditional welding method. The hand-held welding gun replaces the fixed light path. The hand-held optical fiber laser welding machine is widely used in the market at present. It can be flexibly applied to various environments. Flexible and convenient, breaking the limit of the workbench. The welding distance is longer.

The hand-held optical fiber laser welding machine is mainly used for long distance. Large workpieces need laser welding products.During welding, the heat affected area is small.The laser welding machine will not cause deformation. Blackening. There are traces on the back of the workpiece. In addition, the welding depth is large. The welding is firm. Melting is sufficient. The convex part of the molten pool will not appear hollow after being combined with the substrate!

The higher the price, the better the quality?

The hand-held laser welding machine is widely used in the market at present. Its cost performance ratio and service life have been recognized by the public. Therefore, the price issue has always been one of the focuses of attention. Compared with other laser equipment. The current market price of hand-held laser welding machine is relatively low. And the operation is simple. It is the general equipment for welding workers.

At present, there are many hand-held fiber laser welding machine brands on the market. But the quality is uneven. Prices are also different.How much is a hand-held optical fiber laser welding machine? In fact, the price of laser welding machines varies from tens of thousands to hundreds of thousands. It mainly depends on the hardware configuration and power of the device.The cheaper the better.There is an old Chinese saying that “the higher the price, the better the quality of what you buy”.

The reason for the price difference of laser welding machine

Hardware configuration and price difference of laser welding machine. The hand-held laser welder mainly consists of laser. Welding head. Power Supply. Water cooler. Sheet metal cabinet. The main reasons for the price difference of hand-held laser welding machines. Brand quality differences of accessories.

Difference between laser power and welding head.

Different models have different prices. It is mainly the difference between the laser power and the welding head. Currently, the laser power used more is 1000W/1500W/2000W. The welding head is divided into swinging head, upper wire feeding and lower wire feeding. You can choose according to your own needs. The price may vary depending on your choice.

Differences between manufacturers of laser welding machines.

The price of laser welding machines varies from manufacturer to manufacturer. Different manufacturers have different brand positioning. Laser technology. Laser technology and labor costs. Because the product quality and welding process are different. The prices of laser welding machines between them will also be different.

After sales guarantee of laser welding machine.

The price of laser welding machine varies according to the service. Generally speaking, whether the after-sales service is comprehensive when choosing a factory. Warranty period and after-sales service response speed will directly affect consumer satisfaction. When selecting the manufacturer of optical fiber laser welding machine. Warranty of laser welding machine. Therefore, the manufacturer’s after-sales guarantee is also an important part. If the after-sales service is not good, when there are technical problems or product problems. No timely response. It will waste a lot of your time and money.

Don't blindly pursue the price and give up the quality

Hand-held fiber laser welding machine is the “new force” of welding tools in the sheet metal industry. Attracted a large number of foreign-funded enterprises and individual private households. However, the product and price are too high. affect sales. Some manufacturers have had to lower their placement prices. Make industrial products become fast moving consumer goods. This is often due to the variable quality of production in transitioning consumer markets. Therefore, when choosing a fiber laser welding machine, you can’t just look at the price. While ignoring the welding process, quality and after-sales service.

Advantages of HANTENCNC laser welding machine.

From the customer’s perspective. If the company does not lose money. Make the maximum concession. The hand-held optical fiber laser welder produced by HANTENCNC is easy to operate. Maintenance costs are also very low.

-

No installation required, easy to operate

The hand-held optical fiber laser welding machine produced by HANTENCNC does not need to be installed. The customer can use the machine directly after receiving it. No installation and training costs, easy to operate. We provide guidance and operation videos for customers. Ensure that the customer can use the procedures and normal production smoothly.

-

Simple maintenance and cost saving

We will provide copper nozzle and safety glasses at cost price. For customers to purchase.Compared with the traditional welding method. The hand-held optical fiber laser welder does not need to use welding wire. Only when the clearance is greater than 0.5mm. Only wire feeder is required.

The maintenance of the equipment is very simple. After the welding work is completed. Turn off the power and clean the welded joints. This can extend the life of the protective mirror and copper nozzle.

-

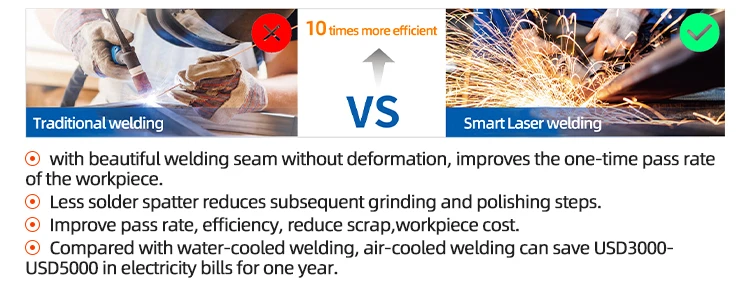

Small power consumption

In addition to the easily worn parts, the machine also consumes electricity and gas. For example, the power consumption of a 1kw machine is 11kw to 12KW per hour. In fact, only 50% to 60% power of 1000 watts is enough to weld metal, and the power consumption is small.

The hand-held optical fiber laser welder only needs 3-5 kilowatt hours of electricity. It costs about 5 yuan of argon per hour. The comprehensive cost is obviously lower than that of traditional welding.

-

Compared with traditional welding methods, laser welding has high efficiency and low cost

The welding efficiency of the laser welding machine is more than twice that of the traditional welding machine.

The welding depth of the handheld fiber laser welding machine can reach 3mm. Compared with traditional welding, laser welding seam weld seam is beautiful, and welding speed is faster. It is easy for employees to operate, and the welding is formed once, which greatly reduces labor costs.

HANTENCNC is the backbone enterprise of China’s laser industry. It adheres to quality management, sacrifices profits and improves quality. We will continue to provide customers with comprehensive and complete laser automation solutions. To meet the customer’s various customization needs.