Today, HANTENCNC will tell you some problems that you should pay attention to when purchasing a laser marking machine.

First of all, the laser marking machine is an industrial product, which is now slowly entering the civilian category. In short, 99% of people buy marking machines to make money. Or for process research and development, processing services, etc.

Laser marking machine purchase considerations:

-

Three main influencing factors of laser marking

Please note that laser marking is only a process in workpiece processing.

Ideally, a workpiece is directly marked. There is no subsequent process, and the pre process does not need to be added. In many cases, it does not exist.

It also needs polishing, pickling, etc.

Due to the manufacturing cost, industrial lasers are fixed wavelengths, without adjustable wavelengths. They are mainly 1 micron fiber lasers source, 10 micron carbon dioxide lasers source and other types of lasers source.

In short, the fiber laser marking machine can mark all metals and some nonmetals. Carbon dioxide laser marking machine can mark all non-metallic materials, and the effect is very good. UV laser marking machine can mark glass, plastic, leather and other materials.

HANTENCNC can mark sample materials for customers for free before the transaction is concluded. Test whether the marking effect meets the production requirements of your company. If the result of the finished product is satisfactory, we can talk about the cooperation and other issues later.

If you have a variety of workpieces to process, the best strategy is to find a strong manufacturer. For example, we will give you the most affordable price and the highest quality laser marking machine equipment.

-

Price comparison

In this regard, it is especially important to point out that it is best to use manufacturers that produce their own controllers and software. There are many foreign trade companies in China without their own workshops. After purchasing their equipment, if you have problems, they will mostly prevaricate. Because he can only do simple operation training or replace modules. Other technical problems can’t be solved, or you can find a supplier to solve the problem. It takes a long time to delay your production and make money.

-

Machine life

On the basis of the first point, a little information should be added to facilitate technical and economic decision-making.

The service life of ordinary optical fiber laser marking machine is generally more than 100000 hours. Ultimately, it mainly depends on the service life of the laser, as well as the operating environment and normal maintenance.

With the increase of types of laser marking machines. If the laser marking machine is used for a long time, each part will definitely be worn. Machine problems also increase frequently. The service life will also be shorter and shorter.

And three starting points for thinking about “workpieces, machines and capital”.

All laser marking machines produced by HANTENNCNC meet the above three requirements.

Application of Laser Marking Machine in Automotive Interior Trim Parts.

With the continuous improvement of industrial processes. Laser marking machine equipment has been increasingly used for the processing of automotive interior. Automotive interior mainly refers to automotive products used for internal modification of automobiles. It covers all aspects of the car interior. For example, automobile steering wheel cover. Car cushion. car foor mat. Car fragrance. Car Pendant. The interior and storage box are all automotive interior products.

The laser marking machine can be used not only for various fabrics. Car seat covers made of leather and synthetic materials.

Personalized laser carving and punching processing is carried out on the surface of pillow case. It can also be cut according to different models and sizes. The cutting, carving and marking processes are completed on the same equipment. It greatly improves the processing efficiency and the added value of products. Today, the editor of HANTENCNC is here to talk about the application of laser marking machine in automobile interior.

-

Application of laser marking machine on leather fabric steering wheel cover

The steering wheel cover not only protects the steering wheel from wear. It can also increase hand feel and friction. In turn, it can enhance the reaction sensitivity and safety when driving. It can also reduce vibration absorption. The steering wheel cover is very decorative. Make the interior of the car more fashionable.

-

Application of Laser Marking Machine in Automobile Cushion

Leather is now available on the market. Artificial leather. Nylon. Chemical fiber. Artificial wool. Polyester wool and other different materials for car seats. The processing of automobile cushion can not be separated from laser equipment. For example, hollow hole drilling. Cut. Engraved patterns. Fabric burning, etc. Laser processing precision is high. Fast. Save time and effort.

-

The application of laser marking machine in automobile foot mats

Car mats absorb water. Vacuum. Decontamination can effectively avoid residual moisture on the sole. The dirt is caused by the clutch. Slip between brake and throttle. Avoid potential safety hazards. Reduce the possibility of interior contamination and damage. After all, cleaning the floor mats is more convenient than cleaning the interior upholstery. More economical. The suede car floor mats can also completely absorb the remaining noise and sound echo in the car. Protect hearing from damage. Suede carpet mats can also be laser processed. Various patterns are carved on the suede floor mats with a laser marking machine. Let the car mat no longer monotonous.

Other laser marking effects

-

Aluminum blackening

The use effect of aluminum oxide blackening laser marking machine has been a hot topic in the marking industry. Many people say that the laser marking machine is fast and efficient. The printed pattern is clear and beautiful. So it is very popular. Like the iPhone shell, the marks on the keyboard, the lighting industry, and so on. This is a MOPA fiber laser marking machine with adjustable pulse width (also known as full pulse width laser marking machine). Ordinary laser marking machines can only print gray or black gray text messages on aluminum products. It is different from ordinary optical fiber laser marking machine. The fiber laser marking machine can directly convert magnesium aluminum. Aluminum oxide and various aluminum materials are black. However, ordinary optical fiber laser marking machines cannot do this.

The mechanism of anodized aluminum blackening is through focusing high energy density laser. The anodic aluminum oxide layer with a film thickness of 5-20um is further oxidized in a very short time. And the mechanism of surface material is changed.

The principle of aluminum blackening is based on nano effect. The size of oxide particles is nanometer after laser treatment. The light absorption performance of such materials is increased. Thus, visible light can irradiate the material and be absorbed. The visible light reflected is very little, so it is black when viewed by the naked eye.

At present, MOPA laser marking process is adopted for mobile phone LOG and adaptation information on the market.

-

Colored stainless steel

Basic principle of stainless steel color marking. It is to use the laser heat source with high energy density to act on the stainless steel material. Make its surface generate colored oxide. Or a colorless and transparent oxide film can be formed. Because of the optical interference effect of the film, it has a color effect.

In addition, by controlling the laser energy and parameters. Different colors of oxide layers with different thicknesses can be achieved.

Even realize color gradient marking. The application of laser color marking is a good supplement to the appearance of stainless steel products. In addition, stainless steel itself has good corrosion resistance and excellent decorative advantages. Stainless steel products with color patterns are more widely used.

-

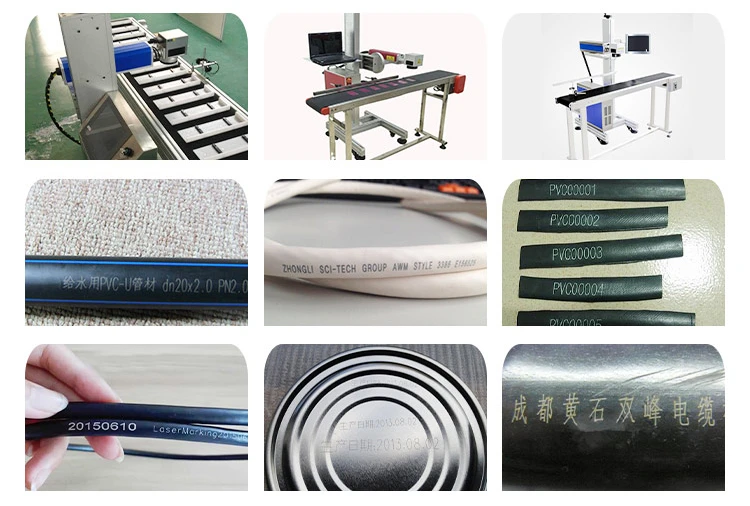

Online flight marking

Online flying laser marking is the most specialized laser application technology. The optical fiber laser marking machine is combined with the assembly line. In this way, we can greatly improve our work efficiency. It is mainly used for marking on the outer packaging production line. E.g. wire/cable. Moulded and extruded products such as tubes and pipes. Online flying laser marking machine is relative to static laser marking machine. As the name implies, it is a machine that laser sprays code on the surface of the product when the product is moving beside the production line. Cooperate with industrial automation. When the workpiece arrives, the marking is completed within a certain period of time. It is an embodiment of automation. The flight laser marking machine can automatically generate batch number and serial number. No matter how fast the product flows. The output of marking light source is stable. The marking quality will not change. So the work efficiency is high. Special power saving. This is also the practicality of the flying laser marking machine.

We are an industrial and trade integration company with our own production workshop. The quality of the laser marking machine products is 100% guaranteed, and 24-hour after-sales service is also provided.

Of course, if you have any problems with laser technology. You can contact HANTENCNC’s official website email and WeChat at any time. If you think this message about the laser marking machine is useful to you, you can forward it to your friends to share.

Thank you for watching.