The art of engraving metal has come a long way. In ancient times, people used hammers and chisels. However, in today’s world, human civilizations are more advanced and capable of doing work faster. Modern tools are quick, accurate, and very easy to use. A laser marking machine for metal is one of the most popular ones in this case.

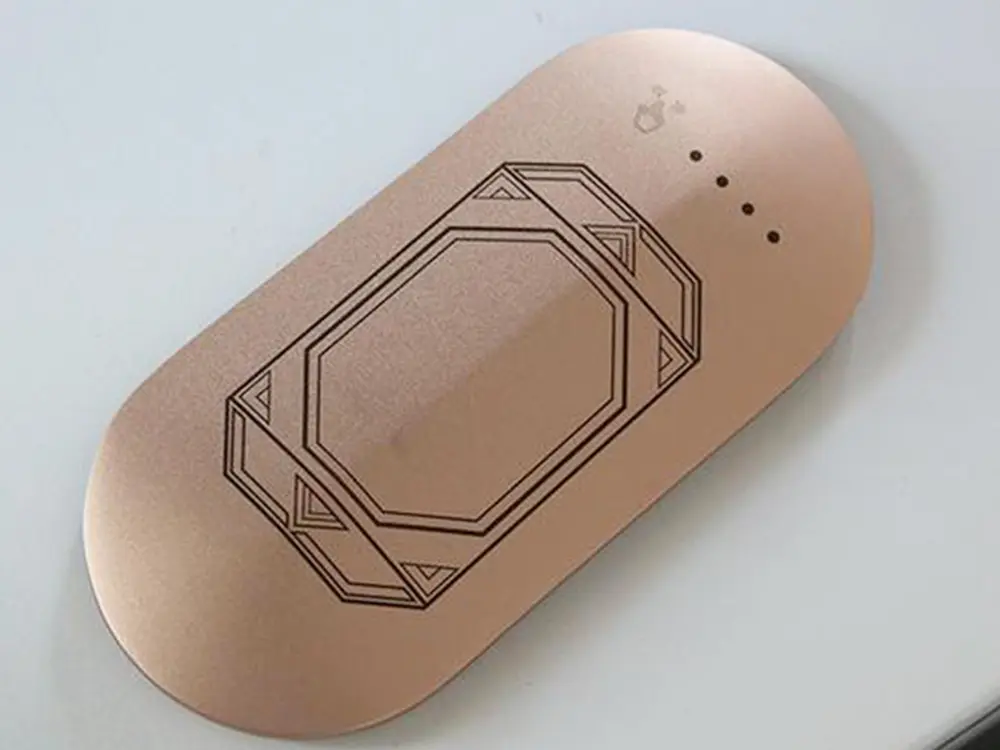

A laser marking machine for metal can cut out artwork, logos, serial numbers, barcodes, and many more. There are lots of opportunities with this fantastic device. This article will try to highlight some basic things about this device. It also talks about some opportunities that you may get using this device. Let’s get started.

What is a Laser Marking Machine for Metal?

A laser marking machine typically cuts, engraves, etches, or changes some properties on the material surface. This way, they create marks on the surface that are highly visible from the outside. It doesn’t need ink or tools to work. Instead, it uses a high-power laser beam that can be produced in several ways.

A laser marking machine for metal is especially suitable for engraving metals. It doesn’t mean that this device cannot work with other materials. However, there are some limitations, though. For example, the CO2 laser is highly suitable for engraving non-metals since its wavelength suits those materials. On the other hand, a fiber laser marking machine creates a laser wavelength that can efficiently develop marks on metals.

A laser marking machine for metal is widely used in a wide range of industries. It can be medical, automotive, manufacturing, car industry, or even electronics. Although, you may not get similar results on different metals. Also, you may find some limitations with laser engraver for metal for deep engraving.

What can a metal engraving laser machine do? It can do a lot of stuff. It can make patterns, data matrix codes, serial numbers, QR codes, and pictures. They are perfect for mass production. All you need to do is set up the design and implement it on your laser machine.

Metal laser markers are amazingly fast and don’t need touching. You also don’t have to worry about the device wearing out over time.

Types of Laser Marking Machines for Metal

There are several types of laser marking machines. They can not offer you the same results. Let’s learn more about why.

Fiber laser marking machine

This device is the most popular choice for metal. This specific laser machine is renowned for its efficiency, long-lasting nature, and robustness. Fiber lasers work well on almost all metals. This device can do it all if you want to carve small features and make lines with high contrast.

CO2 Laser Marking Machine

A CO2 laser marking machine is naturally ideal for producing organic materials. However, most people may not know that they can also work with metals using this device. As you know, many metal parts come with coatings or paintings. You can only use CO2 to remove and expose the layer underneath these coatings. This way, you can create an astonishing mark on metal parts.

UV Laser Marking Machine

These lasers work shorter wavelengths, typically creating precise and smooth marks. They are particularly useful for marking tiny areas on sensitive materials. They are primarily used in electronics, jewelry, and micro-nano tech industries.

MOPA Laser marking Machine

Want color engraving on stainless steel? MOPA lasers are your best bet. This laser marking machine for steel typically creates pulsed laser widths. The great thing about this machine is that you can control the pulse nicely. Because of this, you can make a wide range of markings with varying contrasts, even colored patterns. Note that titanium and stainless steel are widely popular for laser color marking.

Green Laser Marking Machine

A green laser marking machine is ideal for highly reflective metals. This laser generally prevents unwanted reflection and creates sharp and detailed marks.

These machines are also suitable for marking electronic components and delicate materials that require a lower heat-affected zone.

Why Use a Laser Engraver for Metal?

There are many reasons to choose a laser engraver over traditional marking methods. Here’s why:

(1) Laser engraving typically does not fade, chip, or wear away. If you use paintings or other methods, they can not offer a long-lasting service life.

(2) Laser marking needs no contact. Eventually, you can ensure no damage to the object. There

(3) A Laser marking machine for metal is high-speed and accurate. They can mark hundreds and even millions of products at a time with great precision. With this level of speed, you can make detailed artwork. Indeed, laser marks are clean and high-contrast.

(4) Unlike traditional methods, a laser marking machine for metals needs low upkeep. There’s no hassle of changing consumables. Also, you don’t have to replace parts often.

(5) A Laser marking machine for metal is highly versatile. You can mark on almost all types of metals. However, the engraving result may not be the same for all metals.

(6) Since a laser marking machine doesn’t produce waste, it is a very eco-friendly solution. Laser marking offers better solutions than chemical painting, which harms the environment.

5 Popular Types of Metals for Laser Marking

Lasers have different effects on different metals. The following five metals are the most popular ones used for laser marking:

(1) Every industry has a massive demand for stainless steel. It’s an excellent choice for everything from dishes to medical tools. Laser marking machines for metals can create black, white, or even colored marks on them.

(2) Aluminum, on the other hand, is much lighter and corrosion-resistant. Among various types of aluminum, anodized aluminum works best with lasers. Note that aluminum is highly conductive, so you must pay attention to the laser settings during laser marking.

(3) Brass is also a popular metal for laser marking. This metal is widely used in making nameplates, musical instruments, or plumbing parts.

(4) Titanium finds excellent use in aerospace, medicine, and many consumer products. It responds well to laser marking and can produce colored engravings, especially with a MOPA laser.

(5) Copper is highly reflective, making laser marking tricky. However, you can achieve detailed and precise engravings with the right laser (like a green laser).

(6) There are other metals used for laser marking. Many jewelry metals, such as gold, silver, and platinum, can be laser-marked. With a laser marking machine, you can also work with hard metals like tungsten and carbide.

Contact Us Today!

If you have any questions regarding laser marking machines, please contact us. HantenCNC has a very professional team of experts who are always happy to assist you. You can navigate through the product pages for more information about laser machines.