You may be already familiar with laser cleaning and dry ice blasting techniques. You know both of them are prominent cleaning techniques. However, laser cleaning has recently superseded many dry ice-blasting uses. To explain why, see “Laser Cleaning VS Dry Ice Blasting.”

In this “Laser Cleaning VS Dry Ice Blasting” comparison guide, you will first know each method’s cons. Then, you can use these cons to find out the benefits of others. So, this article will typically highlight two main sections.

The first part talks about the cons of dry ice blasting and the benefits of laser cleaning. You will learn how laser cleaning overcomes the limitations of dry ice blasting. In contrast, the second part does exactly the opposite. Finally, you will go through a summary to wrap up the content.

So, this is going to be a really amazing guide. We hope you find useful information here. Finally, you will be able to select the appropriate method for your project.

Limitations of Dry Ice Blasting and Opportunities of Laser Cleaning

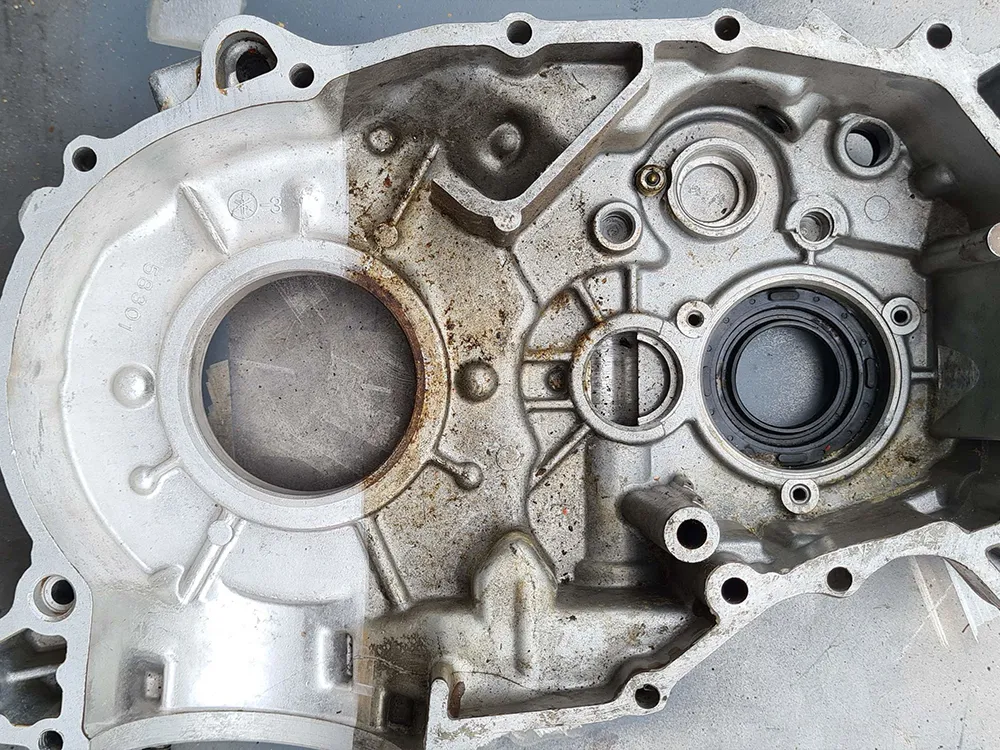

Dry ice blasting is a very popular method. It generally uses compressed air along with dry ice pellets at a surface. The pellets quickly freeze the dirt and break them into dirt or grime. This technique is extremely suitable for delicate components. Typical examples could be found in the electronics and machinery industries.

Even though dry ice blasting works really well on some surfaces, it’s not perfect. Because of these issues, it is not often used in other situations.

Laser Cleaning VS Dry Ice Blasting: Safety Risks

One of the biggest problems with dry ice blasting is the safety risks. As you know, the ice pellets quickly freeze the surface and clean the debris. Dry ice is typically made of CO2, which is not only bad for the human body but also for the environment.

Using this method, you can keep CO2 emissions under control. However, technically, you can only control up to 40%. This means that the remaining 60% goes to the environment. This poses a serious risk of asphyxiation for the users. Therefore, you must ensure proper ventilation; with it, dry ice blasting is safe.

Opportunities for Laser Cleaning

Laser cleaning is one of the safest cleaning techniques in the world. There are several reasons behind this. The first reason is the lack of consumables. Laser cleaning doesn’t need any consumables that might release harmful elements during cleaning. The next reason is that laser cleaning is a completely non-contact process. Thus, the operator does not have to worry about the PPE items that much.

Since laser cleaning doesn’t produce emissions, it’s safe and environmentally friendly.

Laser Cleaning VS Dry Ice Blasting: Operational hazards

Another concern that dry ice blasting has is safety during operation. This process generates so much cold and noise that those operating the equipment must put on jackets and earmuffs to protect themselves. Now, picture what would happen when the dry ice gets in direct contact with your skin, especially at -78 degrees Celsius. It could cause burns or frostbite on your skin.

Opportunities for Laser Cleaning

Laser cleaning is far safer than dry ice blasting. However, it is safer from dry ice blasting because it does not cause coldness and noise. Yet, it provided a very narrow and intense laser beam that may cause skin damage if measures are not taken. Therefore, operators are always recommended to wear protective clothes and goggles.

Laser cleaning is much safer for operators. It provides precision and perfect control over the laser beam. Because of this, there’s less possibility of making operational hazards.

Laser Cleaning vs Dry Ice Blasting: Storage Challenges

Storing dry ice is another challenge. You should store dry ice at a temperature below -78 degrees Celsius. Usually, this level of temperature won’t work with regular freezing techniques. You must employ a special method and use expensive equipment. According to various market research, the price of such equipment can range from 13 grand to 30 grand.

Opportunities for Laser Cleaning

Since laser cleaning doesn’t require consumables, storage is no hassle. Some CO2 laser cleaners may need a gas mixture tube, but this is safer than the dry ice blasting method. A few laser cleaning methods use auxiliary gases, which might add some extra costs. Besides, transporting laser cleaners is easy and quick, and replacing the gas mixture tube is also simple.

Laser Cleaning VS Dry Ice Blasting: High Cost

Dry ice blasting is an expensive method. As mentioned in the previous few sections, the dry ice blaster uses special storage equipment. Also, it costs much more to create dry ice from ammonia, ethanol, or other chemicals.

Besides, finding a reliable dry ice blaster supplier can sometimes be difficult. Besides, the equipment used for blasting is more prone to wear, which needs you to replace frequently. Furthermore, the method also requires an expert hand and high labor. All these add a significant cost to the dry ice blasting method.

Opportunities for Laser Cleaning

Laser cleaning offers you a much cheaper solution. What are the factors that reduce the operating cost of laser cleaning? (1) There is no need for consumables. (2) Less labor-intensive work; anyone with basic knowledge can do it. (3) More maintenance leads to more component replacements. (4) Transportation is also easy.

Laser Cleaning VS Dry Ice Blasting: Ventilation

Proper ventilation is always crucial when dealing with dust. Dry ice blasting is no exception. It produces a lot of dust and CO2 gases, which are extremely dangerous for the environment. Because of this, dry ice blasting is less common in many areas. If used, the facility ensures proper ventilation of the process. This adds an extra cost to the project.

Opportunities for Laser Cleaning

Laser cleaning has a clear advantage when it comes to ventilation. As you know, this method doesn’t produce dust or harmful hoses, so there is no need for extra ventilation systems. As a result, you can do laser cleaning outdoors, reducing the cost of proper facilities.

Limitations of Laser Cleaning and Opportunities of Dry Ice Blasting

You have gone through a broad discussion on the limitations of dry ice blasting. You also know the opportunities for laser cleaning to overcome those limitations. It has now been proved that laser cleaning is the best method compared to dry ice blasting.

However, you should also be familiar with its limitations. Nothing can be perfect, as is laser cleaning. It has two main limitations compared to dry ice blasting: initial cost and slower speed for larger areas.

Laser Cleaning VS Dry Ice Blasting: High Initial Cost

Although laser cleaning saves high operating costs, it costs more than a dry blaster when purchased. Therefore, investing in a laser cleaning machine must be carefully assessed.

A laser cleaner usually comes with a laser source, a laser gun, and other accessories. The last source typically includes the control system and the main laser source machine. This is the main part of the machine which costs the most. However, if your laser cleaner comes with a combo pack, like cutting, welding, and cleaning, then the cost may be higher.

Opportunities for Dry Ice Blasting

In this case, dry ice blasting gives you a cheaper solution. The initial cost is not that high, like a laser cleaning machine. Because of this, this method can be a practice choice for many companies.

Laser Cleaning VS Dry Ice Blasting: Relatively Slow for Larger Areas

Laser cleaning may be slower than dry ice blasting in larger working areas. It is also not suitable for cleaning crevices, such as the inside of a pipe.

Opportunities for Dry Ice Blasting

Dry ice blasting offers better results for larger areas. You can also easily clean crevices using this method. You can use it to clean mold and do equipment maintenance. Since there’s no use of abrasives, dry ice blasting is ideal for cleaning sensitive surfaces.

Laser Cleaning VS Dry Ice Blasting: Which is Better?

So, which is better? From the first part, you have learned five crucial limitations of dry ice blasting. You have also seen the opportunities of laser cleaning to overcome these limitations. On the other hand, the second part of this article highlights the two limitations of laser cleaning.

Now, if you want to overcome these limitations, laser cleaning can help. Selecting the right laser settings can solve the first limitation. In this case, you can consult the help of professionals or turn to our online customer support center. In this manner, you can achieve a result quicker over a large area. However, if you are working with small—to medium-sized components, laser cleaning can give you the quickest and most accurate results.

Let’s come to the second limitation. Laser cleaning may require more capital investment at first, but it is worth it and will, in fact, be cheaper in the long run. Dry ice blasting needs special ventilation, storage equipment, and even frequent consumables.

Laser cleaning is much more environmentally friendly. You can use it outdoors, so there is no need for ventilation. In contrast, this procedure does not require the use of consumables or any particular handling or storage methods. Thus, unlike dry ice blasting, it totally saves operational costs. Therefore, if you consider the total price, laser cleaning is a more cost-effective solution.

Get in Touch With Us!

If you have any questions or are interested in our laser cleaning solutions, please feel free to contact us. You are always welcome to our customer support portal.