Effectively remove rust from various metal surfaces, restoring their original metallic luster, enhancing the adhesion for subsequent processing.

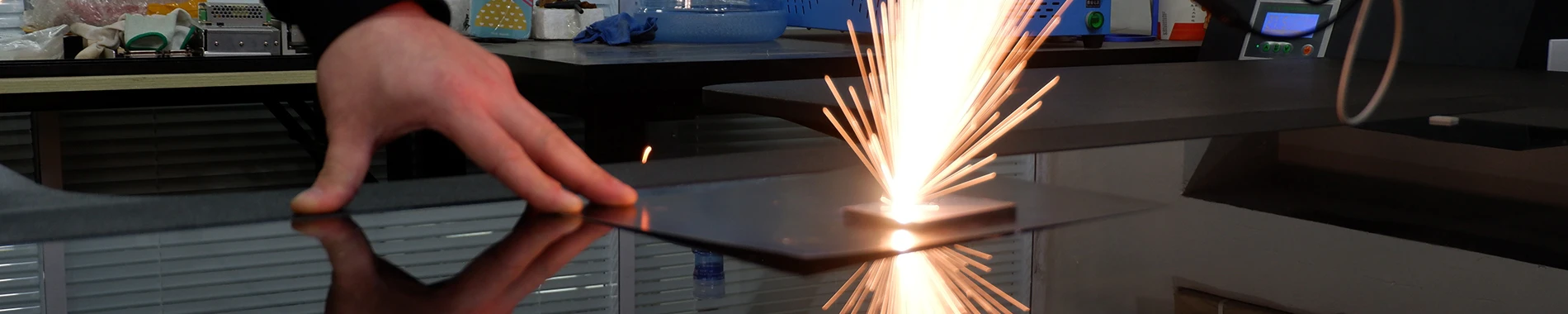

Effectively remove the oxide layer on various surfaces to recover the metal’s original luster and properties.

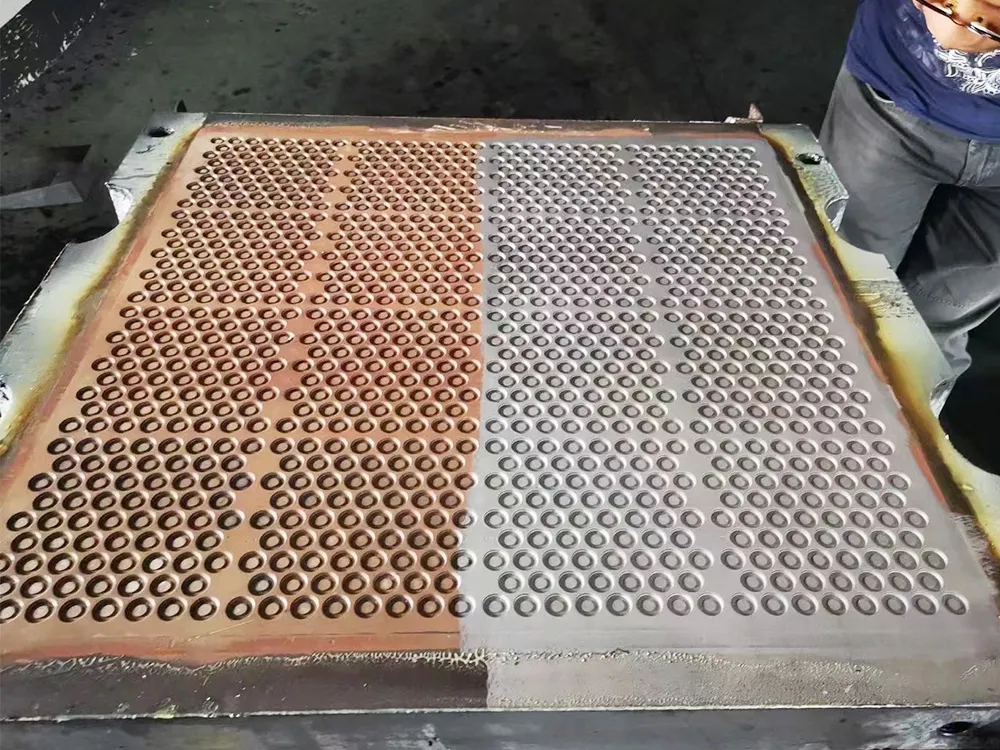

Effectively remove residues on the surface of various molds to maintain clear texture and efficient molding performance.

Effectively removes fire stains and scorch marks from various surfaces, restoring a clean and bright appearance.

Effectively removes graffiti from various surfaces, restoring their original clean and aesthetic appearance.