In this digitalized world, people are exploring new ways to solve problems. Cleaning surfaces is no exception. Traditional cleaning techniques, such as sandblasting or chemical cleaning, can be hazardous. Thus, people are seeking more reliable and effective solutions, such as laser cleaning. A pulse laser cleaner is a suitable option for industrial use.

The 2000W Pulse Laser Cleaner is a splendid example of this. It features advanced technology for cleaning surfaces. This specific laser cleaner is an ideal option for most industrial applications. It is user-friendly and needs less upkeep. You can use it to clean metal, stone, wood, ceramic, and more.

This article mainly focuses on the top 10 industrial uses of a 2000W pulse laser cleaner. This article will teach you why a 2000W pulse laser cleaner is an ideal option. Maybe you can opt for this item for your project.

10 Industrial Applications of 2000W Pulse Laser Cleaner in 2025

#1 Rust & Oxide Removal

Rust and oxide removal from metals can be quite challenging. If you use a traditional cleaning technique, it may damage the surface. Here, a 2000W laser pulse cleaner comes with the best solution.

A pulse laser rust removal machine treats metals using a short burst of laser beams. During the process, it doesn’t come into contact with the metal. Because of this, each metal surface stays safe and shiny. Moreover, this process is faster than any other method used in industrial applications.

Why opt for a 2000W pulse laser cleaner? This power is typically enough to handle most industrial rust and oxide removal applications. You can use it in factories, workshops, and repair centers.

#2 Paint and Coating Removal

We often paint on metal tools and equipment. Additionally, when necessary, we must clean, renovate, or repair them. In this case, old methods like using thinners may be harmful. However, you may opt for a pulse laser cleaner, a much safer and more effective option.

Paints and coatings may come in various types. Powder coating, E-coating, painting, galvanization, anodizing, plating, and polishing are noteworthy. Although you can easily remove paints using thinner, removing other coatings is tricky. Thanks to laser technology, you can effectively clean those coatings as well.

A 2000W pulsed laser cleaning machine is well-suited for this case. How you clean it will stay the same, but you may need to change the laser settings. Additionally, laser-cleaning paints may emit hazardous fumes. Because of this, you need to use good airflow.

A laser paint cleaner can be ideal in many situations. People often use it in auto parts cleaning, restoration, welding, and other repair work.

#3 Oil and Grease Cleaning

Laser pulse cleaners have significant applications in the oil and grease cleaning process. If surfaces are kneaded with oil or grease, they may slip, overheat, or wear out swiftly. This type of problem might lead to equipment failure or costly repairs. Therefore, cleaning oil and grease is essential for better performance and durability.

Aerospace and manufacturing companies require this removal before maintenance or assembly. Sometimes, new parts don’t fit if you don’t clean them properly. Lasers are a safer way to remove them and make them perfect for every approach. Also, the method is eco-friendly and cost-effective for removing oil or grease.

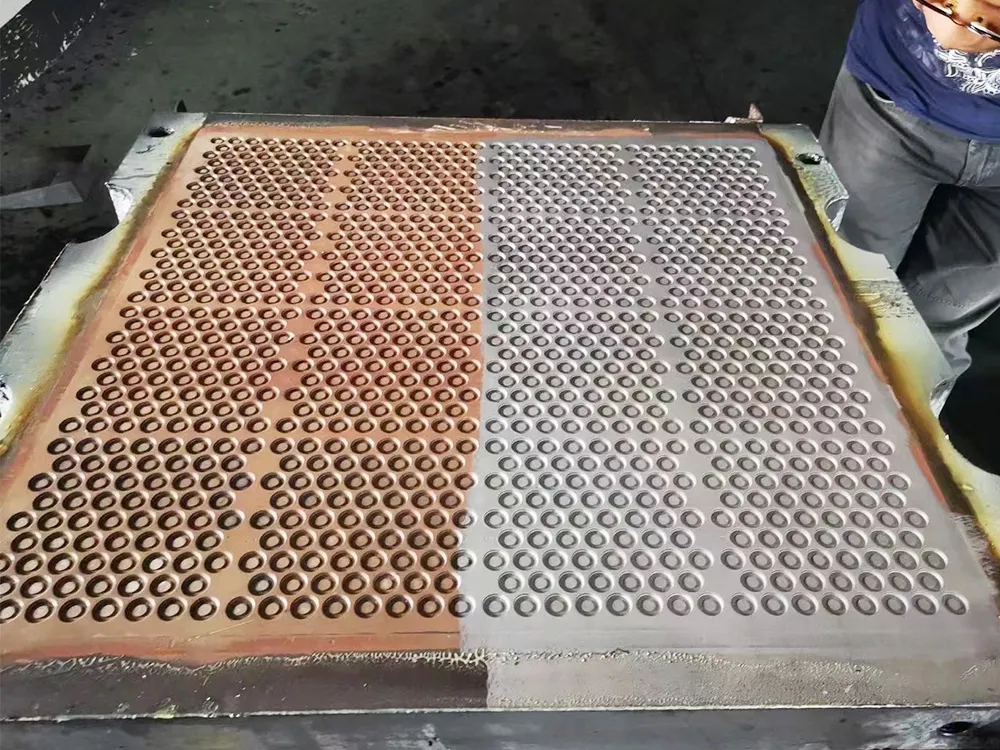

#4 Mold Cleaning in Rubber, Plastic, and Tire Mold Factory

Nowadays, mold cleaning plays a vital role in keeping products smooth and qualified. Mold cleaning is very common in rubber, plastic, and tire factories. Sometimes, molds become dirty from rough and continuous use. If you don’t clean up this dirt, it may affect the shape, surfaces, or product quality. Thus, the process causes defects, poor texture, and weak spots in the product.

A 2000W laser pulse cleaner is an excellent tool for mold cleaning. This cleaner is typically ideal for cleaning molds, especially in hard-to-reach places. Because of this, you can ensure that your mold has the original quality as before, leading to a longer lifespan.

#5 Welding Pre-treatment for Surface Preparation

Welding pre-treatment is essential for ensuring strong and safe welding. If you want to weld metal, you must ensure the metal surface is rust or oil-grease-free. Otherwise, your welding would not be that strong, creating poor and weak welding. Also, pre-treatment reduces the chances of flaws like holes or spots.

Traditional methods like sanding or grinding are often used for surface preparation. However, these methods may damage the materials’ surface, which is unsuitable for delicate parts. Laser cleaning would be an effective way to resolve these problems. Another advantage is that the laser beam won’t damage the materials underneath. Overall, this pre-treatment improves quality, saves time, and reduces the need for rework.

#6 Post-Welding Cleaning for Oxide or Residue Removal

Similarly, the machine is also very effective for post-welding cleaning. After welding, you may find metal surfaces with burn scars, dark oxide layers, and leftover residues. These defects can easily cause trouble at the time of working. For post-weld cleaning, wire brushes or chemical cleaners are less effective. This method is not as perfect as laser cleaning.

Reasonably, laser-pulsed machines are commonly used to remove unwanted surfaces. The use of this approach makes the surface smoother and shinier. Therefore, you can use this method in stainless steel fabrication, pipelines, and other industries. The process enables its quality and ensures a long-term duration. It is a smart and modern solution for post-weld surface treatment.

#7 Auto Parts Cleaning

Auto parts like engine blocks, brakes, gears, and other important parts get rust, grease, oil, carbon, and paint over time. These contaminants can affect performance or safety. Also, it can reduce the lifespan of each material.

As mentioned earlier, the 2000W laser pulse cleaner works perfectly on these materials. The machine protects delicate or high-precision components. You can use the cleaner for small and large auto parts, and it easily reaches hard-to-clean areas. It is often used to prepare metals for repair or assembly. Laser cleaning also helps in restoring used parts for reuse or resale. It is an eco-friendly process for restoration centers.

#8 Pipeline Maintenance and Cleaning

The 2000W Pulse Laser Cleaner is the best-recommended cleaner for pipeline cleaning. Pipelines get rust, grease, and other residues over time, slowing the flow and leading to damage or leaks. Therefore, it is important to keep the pipeline clean for a good flow of fluids.

Pipelines are used in many industries to carry oil, gas, water, and chemicals. As you know, contaminants can be on both the inside and outside. The pulse laser cleaner can also work on both sides. The pipe is safe for oil, gas, or other important handling because it is not rough or chemically based. The process helps with coating or inspection and creates little waste with no harmful fumes.

The method initially seems costly, but its proactive maintenance and cleaning help you eliminate pipeline failures, which might be costlier than this. Moreover, it enhances safety and can prevent explosions, leaks, and other safety concerns. Eventually, this machine will have huge applications and many benefits in this field.

#9 Adhesive and Sealant Removal

The laser cleaner is a precise tool for removing adhesive and sealant from the surfaces as well. Adhesives and sealants are used in manufacturing, automotive, aerospace, and other industries. These materials serve to create bonding or seal gaps. Over time, it becomes dirty and requires replacement or repair. However, removing them once they are cured or aged is difficult.

Laser pulses work on them with powerful light to break down or vaporize the adhesive or sealant layer. In this process, base materials are safe from being damaged or harmed. So, you can employ it on sensitive materials like special steel or plastics.

Before gluing, painting, welding, or reassembling, laser cleaning is ideal. You can also use it to quickly remove old sealants from joints, edges, and seams during a redo or repair. Laser adhesive removal is a fast, clean, and safe process that ensures quality and efficiency.

#10 Semiconductor Industry Applications

In the electronics industry, keeping components clean is important for performance and longevity. Even tiny amounts of rust, oxide, or waste can cause problems during production. It will make microchips and other electrical parts work less effectively.

Laser cleaning offers a chemical-free way to clean circuit boards, silicon chips, and other tools. It uses a highly focused beam to remove microscopic layers from delicate items. As the machine works perfectly, it does not damage the surrounding parts.

If you go for the traditional method, it may leave some residue and cause errors. Manual or ultrasonic cleaning takes time and often damages sensitive items.

You can also use a laser cleaner to remove particles, photoresists, and thin films from semiconductor parts.

Summary

You have gone through a detailed explanation of 10 industrial applications of a 2000W pulse laser cleaner. You can now realize it’s the safest way to remove contaminants from the surface. Moreover, it is an environmentally friendly method because of its chemical-free applications. Surely, you will benefit from using it. For further information, you can contact us. We are here to help you anytime.