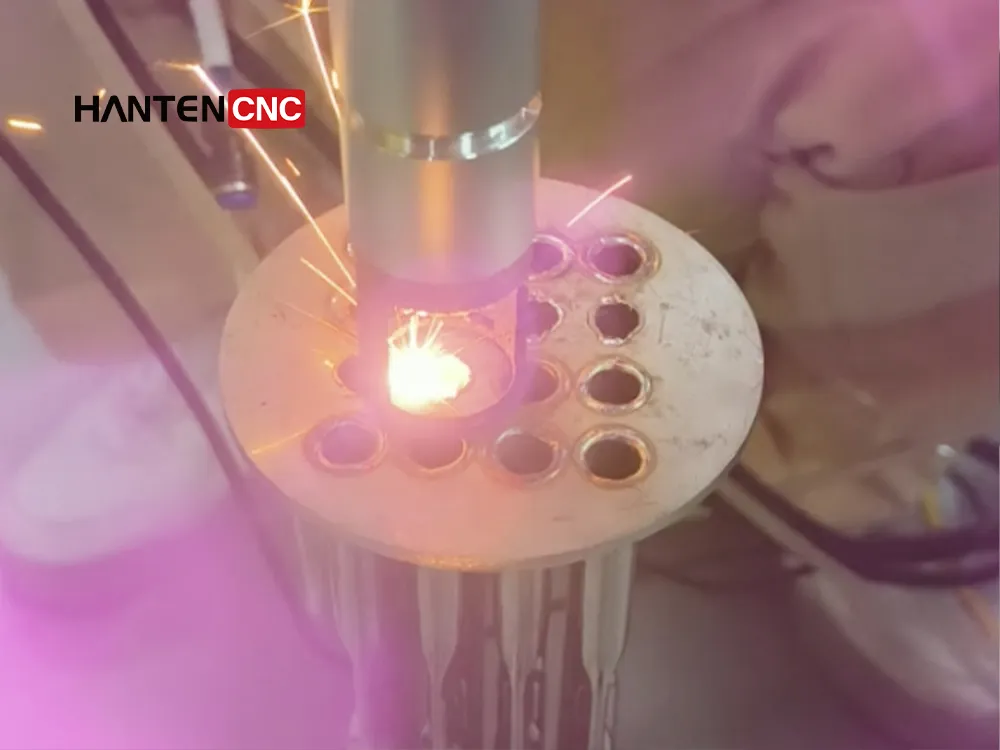

You all are more or less familiar with the welding process. It typically joins two metal parts. This joining process can be achieved through various methods. Laser welding is one of the most common techniques here. Indeed, it is the fastest and most accurate method of welding. However, you must appropriately set the laser welding machine parameters for the best result.

Laser welding machine parameters control how the laser interacts with the material. These include laser power, welding speed, focal spot size, and pulse duration. You must learn to adjust these parameters to ensure high-quality welds.

Each parameter plays a crucial role in the whole welding process. Laser power determines the depth of the weld. Welding speed affects the heat input and weld consistency. Focal spot size dramatically influences the energy density. Finally, pulse settings are critical for specific uses. You will learn more about them in the following few sections.

Why are Laser Welding Machine Parameters Important?

Understanding laser welding machine parameters is extremely important. Why? In one sentence, it plays a crucial role in the success of the welding process. They directly impact the quality, strength, and consistency of the welds. You can get efficient and reliable outcomes by adequately setting these parameters.

Laser Power directly determines weld penetration and fusion depth. If you give too much power, it may create overheating. On the other hand, if you set little power, it may not produce strong welds.

Welding speed also plays a critical role here. It directly affects the heat distribution. Faster speeds create weaker welds, while slower speeds may cause overheating or distortion. The focal spot generally creates the energy density. If the focal spot is misaligned, it can lead to poor-quality welds.

Therefore, understanding the laser welding machine parameters is vital for three reasons:

(1) You can improve productivity by learning the laser welding parameters. Note that optimized parameters reduce welding time and ensure a faster job done.

(2) Proper settings always reduce material waste and can save energy costs.

(3) When you learn more about the laser welding parameters, you can technically work with more metals. For example, many people struggle to work with reflective materials. Most of them think it is impossible to work with reflective metals. But in reality, it is not. All you need to understand is how laser beams work in reflective materials. You have to insert the right laser welding parameters setting.

Key Laser Welding Machine Parameters

In general, there are four key laser welding machine parameters. Combining these four parameters, you can achieve a good laser welding outcome. However, you must know how you are adjusting them. To learn more about these parameters, you can check the user manual that comes with the machine.

Laser Power

Laser power is typically the energy output of the laser beam. You will often find it measured in watts (W). Laser power determines how much heat the laser generates to melt or fuse materials.

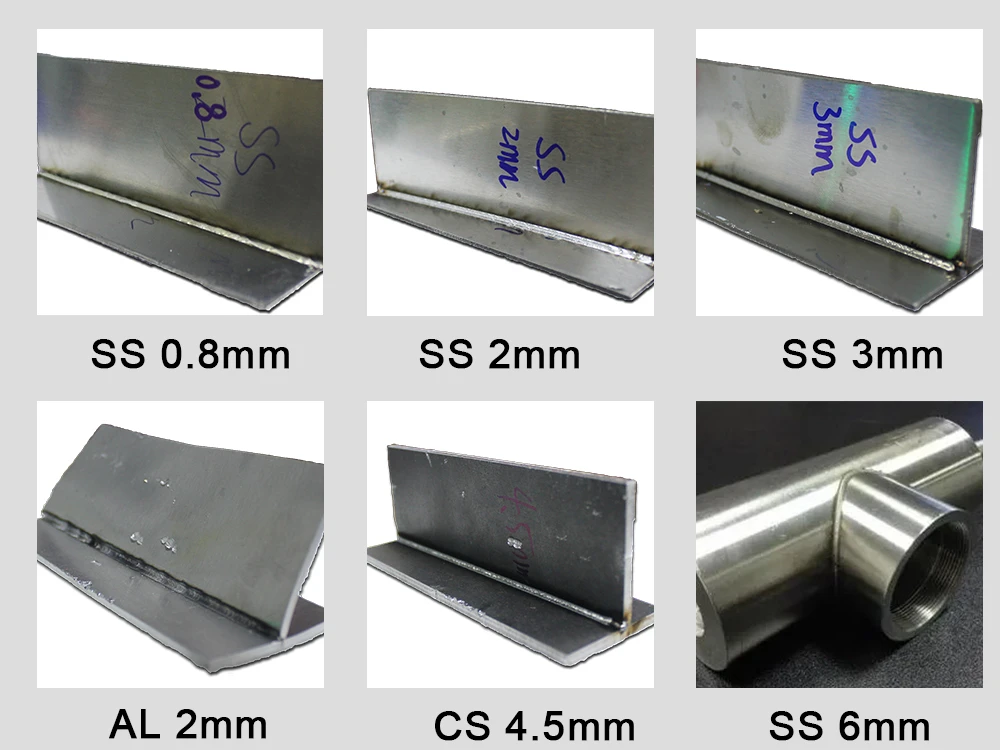

For example, a 1000W laser produces 1000 joules of energy per second. This machine can handle 0.5 to 3mm of stainless steel, 0.5 to 2 mm of aluminum, and so on. Higher power allows for deeper penetration. Note that a higher-power laser welder isn’t always better for all metal parts. They create severe damage to the delicate metal parts. So, you must adjust the laser power based on the metal parts you are dealing with.

The laser power is adjusted in the settings as a percentage. For example, using a 1000W laser welder will set the laser power to 50% for 1mm stainless steel. Most machines use a control panel UI to change all these settings.

HantenCNC laser welders have a digital display where you can easily adjust all the laser welding parameters. This control panel supports 20+ languages.

Welding Speed

Welding speed is how fast your laser welder moves along the weld joint. It is easy to picture in your mind. When you use faster welding speeds, your metal parts take less time to dissipate the heat. Thus, this welding method reduces the heat input. However, you may get weak welds. The opposite happens when you use slower welding speeds.

Therefore, the welding speed can be adjusted using the control panel. Always make sure that the speed and quality of the weld are equal. The best practice is to test the speed on scrap metal parts.

Focal Spot Size

The focal spot is critical terminology in laser tech. When a laser hits a surface, the diameter of the laser is the focal spot size. Remember that the smaller the size, the higher the laser energy. Consequently, the higher concentration means a higher energy density for precision welding.

This laser setting is excellent for thicker materials because the more prominent spots spread the energy over a large area. You can change the size of the target spot by moving the laser head or using the machine’s focus-adjusting settings.

Pulse Parameters

You can generally find two laser welding machines based on laser pulses. The pulsed laser machine produces a short burst of laser energy emitted at intervals. On the other hand, the continuous laser welding machine continuously produces laser energy.

Adjusting this laser welding parameter is crucial for the laser welder you use. Usually, it has the pulse length, frequency, and peak power. Short pulses work best when making small, complicated welds, while longer pulses work best when making thicker welds.

You can also change these numbers to fit your needs by changing the pulse settings on your laser welder. Always do the proper tests to avoid burning or welds that aren’t full.

Factors That Affect Laser Welding Machine Parameters

Laser welding machine parameters heavily depend on several factors. If you don’t know about these factors and adjust the laser welding parameters, you might experience poor results. Therefore, always test settings on scrap material. You could also refer to the user manual for guidance.

Material Type

Different materials respond differently to laser welding. Although steel has a very high melting point, it is easier to weld than aluminum.

Aluminum is reflective and has excellent thermal conductivity. So, some energy is reflected when you focus a laser beam to weld aluminum parts. Also, the created head at the focused area quickly dispersed around it. Therefore, when you deal with aluminum, you must opt for higher laser power.

Material Thickness

Material thickness also affects the parameters of laser welding machines. Thicker materials require more laser power for penetration, while thinner materials require less power to prevent burn-through.

For example, 1mm stainless steel requires 500W laser power, 800 mm/s speed, 5kHz frequency, and a 2mm focus. On the other hand, 1.5 mm stainless steel requires 500W of laser power and 750 mm/s welding speed. Therefore, the laser parameters should be carefully adjusted based on the material thickness.

Shielding Gas

Shielding gas generally protects the weld from oxidation and contamination. Argon, helium, and nitrogen are the most commonly used gases. The type and flow rate of the gas affects weld quality and appearance. Improper shielding might cause porosity and discoloration.

Weld Joint Design and Alignment

If you do further research, you will find that welds may vary. Butt lap and corner welds are three of the most popular type of weld joints. Note that the type of weld joint also affects the laser welding machine parameters.

Moreover, the proper alignment of the welding parts is also crucial. If you hold it incorrectly, you might get weak or distorted in the weld.

Surface Condition

The surface condition of the material is also critical for laser welding. Clean surfaces always offer better results. Since there are no contaminants on it, it absorbs the laser properly. As a result, you can achieve more substantial and more precise welds.

Like other materials, dirt, rust, or coatings absorb laser energy. So, when your object has these on it, the laser welders may not produce the expected result. Did you know that the oxide layer on aluminum alloy has a higher melting point? The same thing happens when your metal part has coatings or rust.

Some Expert Tips for Settings the Laser Welding Parameters

With the proper settings, you can achieve the best results from any laser welding project. If you are a beginner, it is always recommended that you follow the best practices.

(1) One of the best practices for laser welding is testing on scrap metal. It works great, especially for beginners. You might want to adjust the laser welding machine parameters setting when testing.

(2) You can also use laser welding simulations before the actual process. This way, you can predict the possible outcomes. This will save you time and keep you from having to try things over and over again.

(3) You must keep your laser welding machine in good shape. Never forget to clean your device. You can also check the machine setups periodically. When you do it, you must pay attention to the cooling systems and power output.

(4) Follow the recommended settings. You can get help from a professional to get better results.

Conclusion

Throughout the article, you provided a lot of helpful information. You now know what factors generally affect the laser welding machine parameters. You also know which parameters are responsible for which laser welding problems. Therefore, it is crucial to understand laser welding parameters.

It is always wise to follow the manufacturer’s guidelines. As a beginner, you can simply follow the laser welding settings for specific metal parts. As you know, the setting of steel’s laser welding machine parameters won’t be similar to that of aluminum. So, always stick to the recommended laser settings.

If you still don’t get the desired result, you can use a scrap piece of metal parts to check the laser settings. You can adjust the settings based on your experience.

Contact our customer service team if you have more questions about laser tools. Our experts are always ready to help. If you’re interested in laser welding machines, browse our product information pages.