The power of the 10,000-watt-class equipment is about 60kw. Air compressor 22kw, dust removal 15kw. If it is cutting with oxygen, it is about 15 for one hour, and for nitrogen, it is about 40 for one hour.Labor is about 30RMB an hour.Excluding depreciation and venue, the cost per hour is about 200RMB or less.

Just to give an example, 10mm stainless steel, 12000 watts is about 10 meters per minute.600 meters in one hour. The charge for 10mm stainless steel is about 6-8RMB per meter, and there is an additional charge for perforation. Calculated according to the minimum 6RMB, it will cost 3600RMB for one hour.

Of course this is a theoretical state. Not too much difference.

To buy a fiber laser cutting machine, you need to see:

-

Industry

What kind of industry are you in? If you are in the advertising industry, you generally need 1kw, 1.5kw is enough, just pick an economical laser cutting machine. If you are in the metal processing industry, you need to know more and compare them. Choose a better quality one.

-

Accessories

It is the most important part to know what laser to use. Generally, there are IPG, Raycus, Max, GW, JPT, etc. on the market. The first three are the most common, with IPG having the best quality and very, very high prices. Raycus in China has a large market share, but it is said that the quality of the products affected by the epidemic is not very stable. Max is still okay, I think the price/performance ratio is relatively high.

-

Laser head

You can choose RayTools or WSX, WSX is cheaper. Divided into manual focus and automatic focus.

-

Bed frame

To be optimistic about the structure of the bed, you can consider buying a cast iron bed, which has good stability and long life. You should buy a heavier welded bed. There are steel pipe welding, plate tube welding, plate welding, and plate welding are the best. It needs to be considered in combination with laser power.

-

Beam

There are cast aluminum beams, aviation aluminum beams, the impact is not very big.

-

Motor

Yaskawa is the best choice, not only depends on the brand, but also depends on the power of the motor, generally better 1800W, 850w, 400w.

-

Control system

The most common and the best is the FSCUT system, with different power and different models, middle and low power FSCUT 1000, FSCUT 2000, pay attention to the different prices…. There are many pitfalls to avoid

In short, it is necessary to consider comprehensively according to your own needs and your own budget.

Many customers think, since they want to buy a laser cutting machine, wouldn’t it be more appropriate for me to buy a second-hand machine.

With the continuous upgrading of the laser industry and the stability of low-power laser cutting machines in the market, the prices of new laser cutting machines are also falling continuously.

For a long time, many people are struggling to buy laser cutting machines and take over second-hand ones. HANTENCNC has been producing for many years Experience tells you that there are 4 major hidden dangers in buying second-hand:

First understand the core components of the laser cutting machine

- Fiber-optic laser

- Cutting head

- Servo motor

- Chiller

- Air supply system

- The host

- Control System

- Power Supply

- Core components such as machine assembly

All machines have a certain service life, and when these core components age beyond the service life, the machine is prone to failure.

For example: the cut out has slag, and the cut out is not round or smooth. Problems such as impenetrable cutting, power attenuation, no light from the machine, water ingress, etc., are not the only ones to be repaired. If the cutter is broken, you can only find the manufacturer to repair such a large object.

After-sales service

When you choose a second-hand one, then the problem comes, what should you do if there is a problem with the machine and there is no after-sales service? Whether it is necessary to find the manufacturer again for maintenance, and replace the core components such as the laser and cutting head of the entire laser cutting machine, the money added up can buy a new laser cutting machine.

The maintenance costs of different manufacturers are also different, and the field needs to be checked, so when choosing a second-hand cutting machine, it is recommended to consider after-sales service.

The overall structural process level

Attention should be paid to the overall structure and technological level of the laser cutting machine. Now the cutting range is getting wider and wider, which is a test for the overall structure of the cutting machine. Both the overall structure and the level of craftsmanship require higher requirements, and the second-hand cutting machine is completely different from the brand-new ones in terms of craftsmanship and equipment. The technology is constantly innovating every year. You may think that buying a second-hand cutting machine to save money is actually a waste of money.

Cost-effective

To choose a product with high cost performance, you should look at the scope of application and the working strength of the machine when choosing a product. Of course, the price of new equipment is also sinking. It is superior to the old equipment in terms of service life and structural function, accuracy and maintenance. The cost is much better than that of the old equipment. With the price drop of lasers, the configuration performance of the earlier lasers has not been updated, and the price is also expensive. The seller is because it was expensive when it was bought, and the price is not cheap when it is sold. Lasers Every year there is a light attenuation. The longer the service life is, the more severe the light attenuation is. This is an inevitable common problem of electronic products. It is recommended to use a new machine for a large amount of processing. The old machine, whether it is power loss, process decline, or slow down, In the long run, it is not possible to start with. If the cutting volume is small and the processing requirements are not high, the price is suitable. In general comparison, when choosing a laser cutting machine, you should know whether to buy a new one or a second-hand one.

There are many factors that affect the laser cutting machine

- The size of the machine tool, generally speaking, the larger the size, the more expensive the price;

- The selection of core components. Core components such as lasers, cutting heads, and chillers will directly affect the quality of the laser. When purchasing equipment, you must confirm the brand and model of the components used. Prices vary greatly depending on the brand and model;

- Investigate the manufacturer’s strength, assembly process, and after-sales service

These are the factors that affect the price.

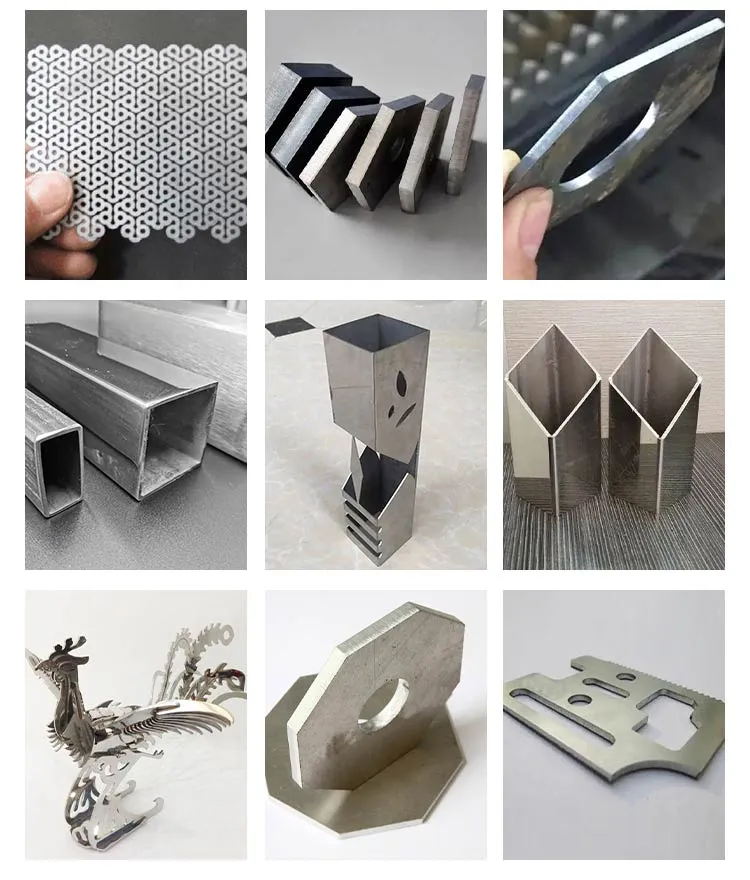

The use of laser cutting machine

I won’t say much about the definition of laser cutting machine. Simply put, it is to use a laser to cut objects, and it has a wide range of uses.

The following are the uses of laser cutting machines:

- Plate cutting

- Cloth, leather

- Graphic engraving

- Signage

- Badge

- LOGO

- Educational teaching aids

- Handicrafts

- Small toys

- Fitness equipment

- Medical devices

Laser cutting machines are widely used, and there are many materials that can be cut.

Materials that can be cut

The following are some materials that the laser cutting machine can cut, welcome to add more:

- Acrylic

- wood

- fabric

- leather

- Metal

- metal processing

- medical instruments

- Fitness Equipment

- Chassis cabinet etc.

Available in different materials depending on the power range.

Han’s, Hongshan, HANTENCNC and Markor are relatively common in the industry. They are equipped with compressors and post-processing equipment for compressed air. Laser cutting has relatively high requirements for air quality. There are relevant national standards that can be queried. Compressed air quality Failure to meet the standards will lead to poor processing such as cutting effects and burrs. Reduce wipes and replace lenses, improve product yield and production efficiency, and recover the investment cost in two months. I believe our company’s technology can help you. The professional commissioned compressed air continues to meet the standards stably. If necessary, you can contact the official website mailbox and WhatsApp.