Single-pendulum and double-pendulum welding are widely used welding techniques. Both are advanced forms among other welding methods. The Single Pendulum and Double Pendulum offer multiple features, making them suitable for a wide range of versatile applications. They both have their unique working principles to operate the welding process. For example, the Single Pendulum works in one direction with a single head, and the double pendulum has two heads that move both horizontally and vertically.

Here, the term “heads” refers to the welding torch or head swings. For the double pendulum, these torches remain on the X and Y axes.

People utilize these two methods for high-precision work. From automotive to robotic arc welding and billboard, they provide services in creating the parts. In this article, we provide comprehensive details about these two welding techniques. Hopefully, this might meet your requirements.

Understanding the Swing System in Laser Welding

The swing system is crucial in laser welding. It refers to a system that decides the movement of the laser beam. This system enables you to create a path for the beam according to the specified pattern. Thus, it helps to spread the heat more evenly to the joints. Additionally, it enhances the quality of welding by reducing flaws and mistakes.

A Single Pendulum has one swing system that typically follows a linear path. On the other hand, double pendulum welding has two systems. It allows you to hold two movements simultaneously. As a result, it easily increases efficiency and precision during welding.

What is Single-Pendulum Laser Welding

Single-pendulum laser welding is a method where the head oscillates back and forth during welding. When it passes over the material, it moves in one direction. The motion is similar to that of a simple pendulum. This way, it helps distribute the heat more evenly and strengthens the connection. People commonly employ it for small welding tasks. Additionally, you can utilize it in tight spaces for welding. Its design allows it to function in areas that are challenging to access.

Overall, the technique is suitable for performing simple operations on thin materials. It improves joints and reduces weak spots and defects.

What is Double Pendulum Laser Welding

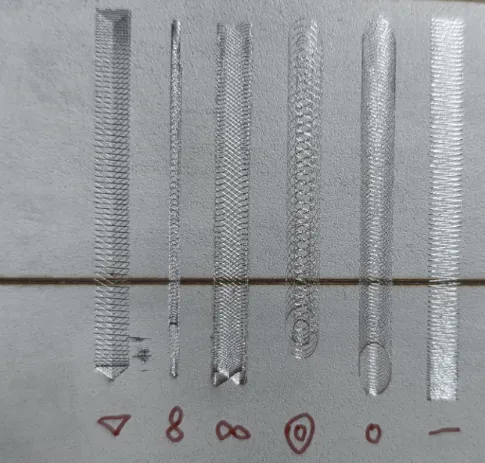

The double pendulum welding operates in two directions during welding. This method utilizes two heads for welding metals. One moves horizontally, and the other moves vertically, simultaneously. It swings side to side and up and down, like two pendulums working together. The method follows a wide range of patterns, like triangles, circles, and eight shapes. This variety typically increases flexibility and offers many advantages. It spreads heat far better than single-pendulum welding.

By using this method, you can easily handle intricate designs and complex shapes. Moreover, you can improve joint strength and minimize defects.

Single VS Double Pendulum Laser Welding: What’s the Difference?

The common thing between them is that both follow pendulum oscillation techniques for welding. Otherwise, there are lots of differences between these two welding techniques. If you want to know the differences, then this is the right place for you. Below, we will break down everything part by part.

Structural Performance & Flexibility of Movement

Regarding structural performance, it encompasses welding quality, position, and heat input. Single-pendulum welding has unidirectional movements. It is suitable for light jobs. You can get excellent performance for narrow joints. However, it will provide you with stable performance on thin and flat surfaces.

On the other hand, double pendulum welding is an advanced method. This method provides more control and versatility during welding. It helps you work on complex operations. It can deal with curves, spaces, and thicker materials. Extra motion helps to create strong joints and welds. Both systems have good heat distribution capability.

Welding Effect & Precision

A single-pendulum weld gives a clean, smooth weld on plain surfaces and joints. If you are keen to work with the single-pendulum welding method, you need to understand its effects. Additionally, consider the precision of certain materials.

As you are aware, a single pendulum is more suitable for basic welding tasks. We do not usually recommend using it for welding thicker materials. However, you may want to consider this method for welding thinner surfaces.

Double pendulum welding will provide you with high precision when used on thicker materials. If you require deeper penetration or strong welds, this option will be suitable for you. This method is highly popular for its high accuracy.

Maintenance Requirements

The choice between the two options can sometimes depend on maintenance requirements. A single-pendulum welding machine is much simpler and easier to operate. This machine features a user-friendly manual and fewer moving parts.

On the other hand, the Double pendulum welding machine is relatively complex due to its dual movements. They have more parts for adjustment. If you want to work with thin materials, you can adjust the settings accordingly. Once you learn how to operate it, the machine will ultimately benefit you.

Overall Efficiency

Both welding machines are effective in their specialized welding work. As mentioned earlier, single-pendulum welding is suitable for basic welding work. You can use it in automotive, construction, or other manufacturing sectors for simple tasks.

The double pendulum welding is better for extensive applications. People opt for it because it gives many efficiencies during welding. You can use it in aerospace, automotive, and other sectors for durable work.

Cost

A single-pendulum welding machine is less expensive due to its simplicity in design. The equipment used in this machine is also cheaper. Maintenance and repair costs are also lower. For this reason, people with a lower budget tend to prefer this machine.

On the contrary, a double pendulum is comparatively costlier. The complex motion, setup, and maintenance of a double pendulum are the main reasons for its higher cost. However, utilizing it will yield long-term benefits. Please make your decision carefully before purchasing it.

Which one Should You Prefer the Most?

When choosing between them, consider a few key factors to determine which one is best suited for the job. A single pendulum method will work well if you need to weld thin materials. Most people use it for basic welding work. Additionally, you are already aware that this method is relatively inexpensive and produces simple joints.

For higher accuracy, complex work, and deeper welds, double pendulum welding is the best option. It provides flexibility and more control, resulting in the best possible outcome. Although it costs more, it’s worth it for advanced jobs. Therefore, select the option that matches your quality needs, machine setup, and budget.

Your Project Needs

When choosing the correct method, you must first know what your project needs. If it always involves high quality and strict precision, then opting for a double pendulum is crucial. For this, you can thoroughly research all aspects of your project. Like the welding volume, type of materials, joint quality, strength, and productivity are noteworthy.

The Level of Welding Quality

Quality heavily depends on the project type and the welding method you follow.

Single-pendulum welding has limitations, but it is a speedy process. It is ideal for welding thin pieces, resulting in clean joints. The disadvantages include spattering and reduced effectiveness for deep porosity.

Double-pendulum welding is highly effective in ensuring quality control. You can use it for making deeper, wider, and stronger welds. It is more precise and reliable for every task. This versatility is the main reason for its vast popularity.

Device Configuration

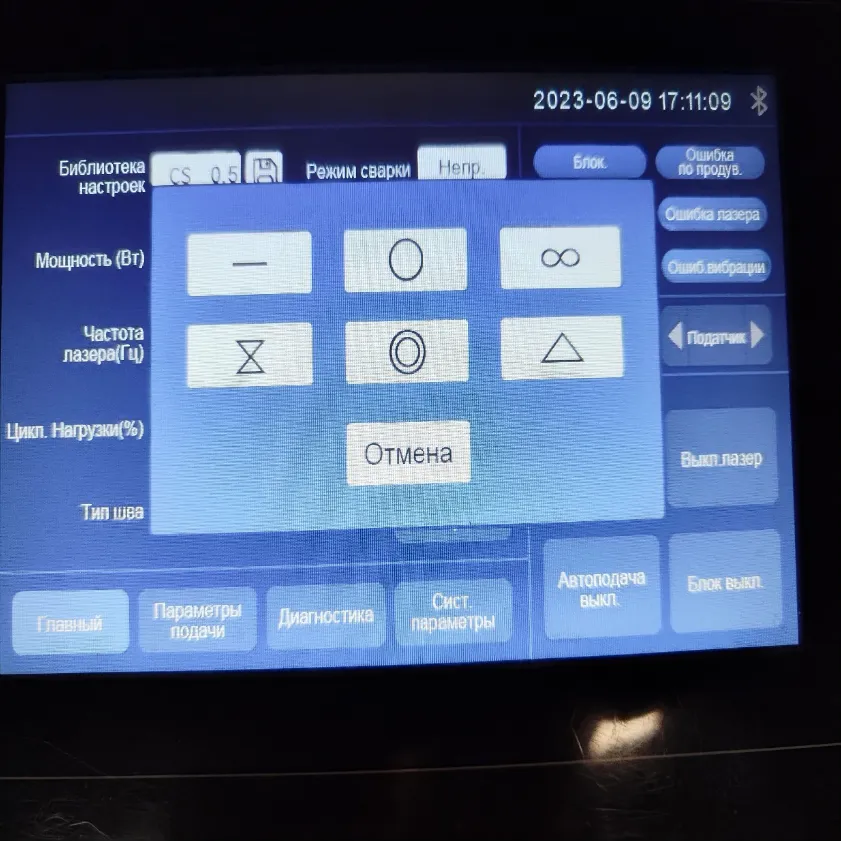

For practical and detailed work, device configuration plays a key role in welding. Single-pendulum welders utilize one-way movement for arcing. It uses a welding torch for a secure power supply connection. There is a control panel that allows you to set parameters according to your requirements. These machines are easier to install and require less programming.

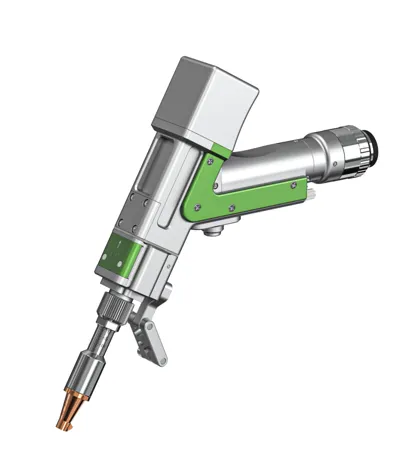

Double-pendulum welding uses two heads, a laser source, and a focus lens. You may opt for a CCD monitoring system, which is optional for the buyers. For better control, it offers a control system, feeder, and power supply with well-kept wiring. Thus, it allows you to work with high efficiency by reducing defects.

Budget

The budget is also an essential factor to consider when making a purchase. The simplicity of design and equipment makes single-pendulum machines affordable. This machine is less expensive and minimizes maintenance expenses. Hobbyists or small business owners prefer it for simple projects.

In contrast, the double pendulum system is costly and requires skilled workers to operate the machine. This increases overall expenses. It may seem initially expensive, but it will benefit you through mass production. Consequently, it has a long-term value.

Explore 6 Modes of Double Pendulum Laser Welding Techniques

Using a double pendulum for laser welding is worthwhile. The machine features six modes for welding materials according to specific requirements.

The straight-line welding beam moves along the line for a linear joint. Circle mode helps spread heat and welding in a circular shape.

8-shape modes are ideal for deep welding, mostly. Double circle mode operates well to strengthen weak joints. To fuse in better condition, the triangle and double triangle modes are suitable. You can easily weld thicker materials by using this method.

Contact Us Today

At this point, you know the advantages and disadvantages of both methods. Now, the rest depends on your decision. If you need any clarification, please don’t hesitate to contact us. We have a team available to answer your questions or provide you with the information you need.